6

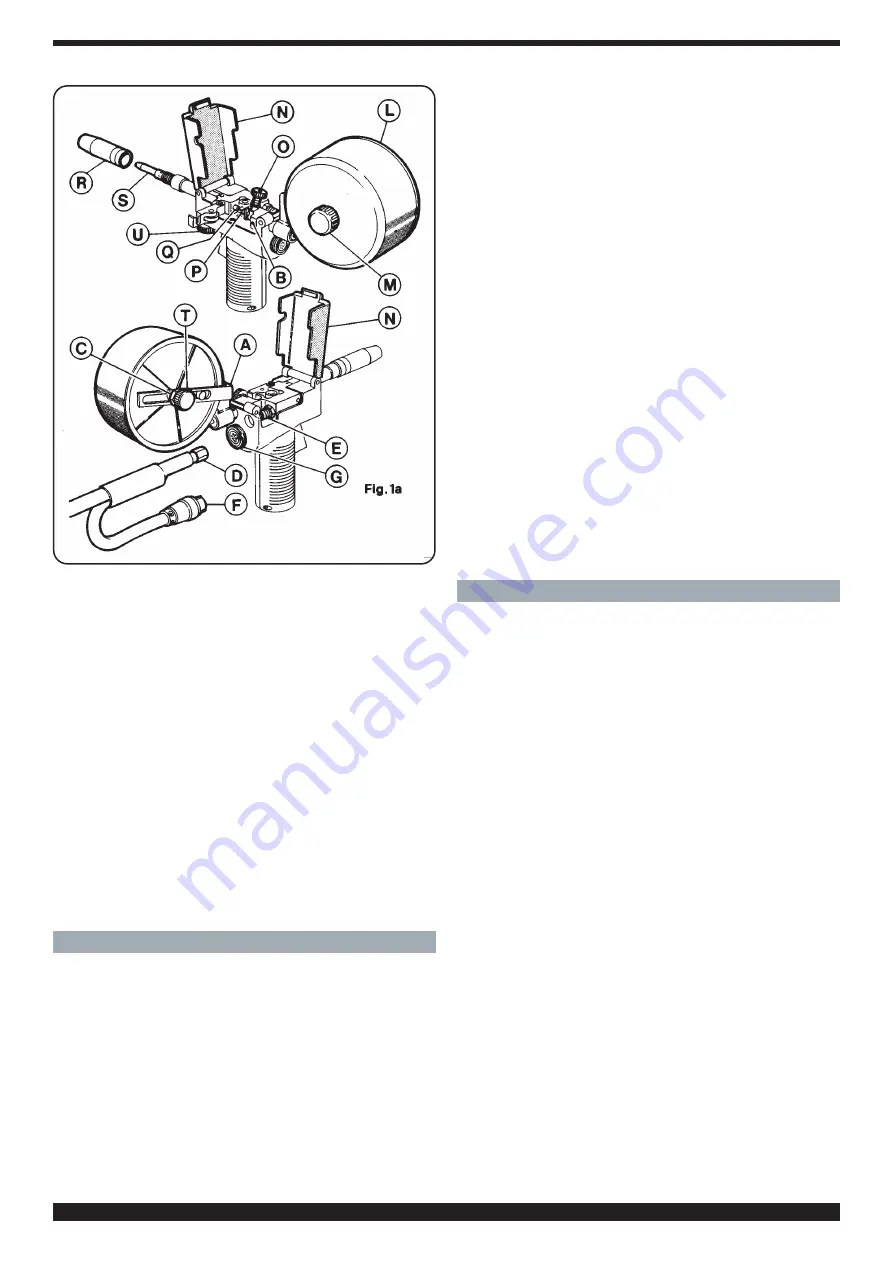

A)

Spool Support

B)

Lock screw

C)

Lock nut

D)

Fitting

E)

Fitting

F)

Connector

G)

Connector

H)

Fitting

I)

Connector

L)

Spool cover

M) Knob

N)

Spool cover

O)

Roller presser pin

P)

Teflon tube

Q)

Teflon tube

R)

Gas nozzle

S)

Contact tip

T)

Knob

U)

Wire speed control knob.

4. INSTALLATION

4.1 INSTALLING THE SPOOL-GUN ART 1562

This spool-gun has been designed for use with genera-

tors art. 582 and art. 584 using the extension cable art.

1324. Other set-ups may be used provided that the com-

ponents are compatible.

Turn the spool support (A) to the position required and

lock it in position using the lock screw (B).

Depending on the welding type and location, it may be

necessary to change the maximum rotation angle of the

spool support (A). To change the angle of the spool sup-

port, loosen the lock nut (C) and move the spool contain-

er along the support slot.

Using the spanner supplied, screw the fitting (D) of the

extension cable (art. 1324) to the union (E) of the spool-

gun. Connect the connector (F) of the extension cable to

the connector (G) of the spool-gun.

Connect the extension cable (art. 1324) to the generator

following the instructions given in section 3.5. E2. of the

generator instruction manual.

4.2 INSTALLING THE JAW-FEED WIRE FEED UNIT

ART 1428

This jaw-feed wire feed unit has been designed for exten-

sion to generators art. 582 and art. 584 using the exten-

sion cable art. 1324. Other set-ups may be used provid-

ed that the components are compatible.

Screw the fitting (D) of the extension cable (art 1324) to

the wire feed unit fitting (H). Plug the connector (G) of the

extension cable into the wire feed unit connector (I).

Connect the extension cable (art. 1324) to the generator

following the instructions given in section 3.5.E2. of the

generator instruction manual.

Select a wire-feed roller with a suitable groove. Fit the

wire spool. Insert the wire into the wire drive motor and

ensure that the wire-feed roller groove and the wire are

aligned.

Connect up the welding torch.

5. WELDING GUIDELINES

5.1

MILD STEEL WELDING

To weld mild steel use 75% Argon + 25% CO2 or 100%

CO2.

Select the welding voltage you require by means of the

welding voltage switch on the generator.

Approach the point to be welded and press the torch

push button (70).

• Adjust the potentiometer (U) (see figs. 1a and 1b) until

the welding noise is constant and continuous.

If the speed is too high, the wire will tend to get stuck on

the workpiece causing the torch to bounce back.

If the speed is too slow, the wire will melt irregularly or

else the arc will switch off.

When you have finished welding, switch off the machine

and shut off the gas bottle.

For the correct welding angle, see figure 2.

5.2 ALUMINIUM WELDING

The machine set-up for aluminium is the same as that for

mild steel with the following differences:

1.100% Argon as welding protection gas.

2. Wire of composition suitable for the material to be

welded.

- To weld ALUMAN, use 3÷5% silicon wire.

- To weld ANTICORODAL, use 3÷5% silicon wire.

- To weld PERALUMAN, use 5% magnesium wire.

- To weld ERGAL, use 5% magnesium wire.

Note for Jaw-feed wire feed unit art.1428

If you are using a torch suitable for steel wire welding, the

same must be modified as follows:

Summary of Contents for JAW-FEED

Page 19: ...19 SPOOL GUN ART 1562...

Page 21: ...21 JAW FEED ART 1428...

Page 23: ...23 JAW FEED ART 1428...

Page 24: ...24...