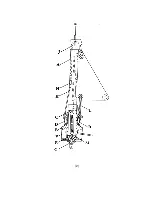

7. Pass the forestay, starting with the swage-end, down

through the halyard top fitting /luff assembly. If the mast is

up, pass a light line through the luff and make it fast to the

cotter pin hole in the swage-end of the turnbuckle using a

piece of wire to make the link. Pull the line while pushing

the luff up the forestay. When the swage-end and wire

appear, screw on the turnbuckle body to prevent the luff

from falling down.

connecting swage stud pushing extrusion up screwing turnbuckle

to messenger line forestay on stud

8. If the turnbuckle thread size is 5/16” in diameter, drill out

the center hole of the bearing with a 21/64” drill.

9. Place a washer over the T-bolt. Add extra washers on top

of the T-bolt to increase the reach of the clevis pin to the

chain plate hole (see photos below).

10. Select the appropriate pair of holes (on the bottom of the

cup) based on the orientation of the chainplate and furling

line. (See page 10 for more information.)Then screw the

antirotation strap, bearing and cup together.

Adding washers to the T-bolt so the Assembling cup, bearing

toggle will reach the chain plate hole and antirotation strap

(7)

Summary of Contents for FLEXIBLE FURLER 2

Page 4: ... 2 ...