WARNINGS –

READ BEFORE INSTALLING OR USING YOUR

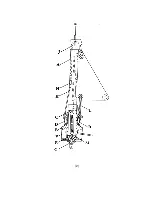

FURLER

Improper installation of the Flexible Furler or improper reinstallation of the

forestay can cause failure of the forestay, and could result in the loss of the

mast and injury to crew members.

PRE-INSTALLATION WARNING:

You must use

toggles

at both ends

of the forestay

. Improper toggling

may cause the forestay to fatigue due to bending stresses.

POST INSTALLATION WARNINGS & SAFETY CHECKLIST:

1. All

clevis pins

and

cotter pins

(especially

turnbuckle cotter pins

)

removed during installation must be replaced.

2.

Turnbuckle threads

must have full engagement.

3. Make sure your furler

rotates freely

.

4. The luff and the inside of the drum

must not touch the turnbuckle

body

. If they touch, furling may unscrew the turnbuckle.

5. The

luff support pin

must be installed, or the turnbuckle will unscrew

and cause dismasting.

6. Insure that the

bearing is not jammed

, as winching with a jammed

bearing will transmit torsional loads to the turnbuckle which could lead

to failure.

7. There must be at least

3” clearance

on the sides and above the

halyard top fitting.

OPERATION WARNINGS & SAFETY CHECKLIST:

1.

Never winch

the unit without checking for jams or snarls. Winching

against an obstruction can sever or cause hidden damage to your

forestay.

2.

Keep your unused halyards

flipped to the after side

of your spreaders

and

lightly tensioned.

3. If the unit becomes hard to furl,

investigate and correct the cause

.

Failure to do so can lead to the failure of the forestay.

USAGE WARNINGS:

The Flexible Furler is NOT designed to be used while your boat is in the

water and passing under low clearance obstructions (bridges, power lines,

etc.) with mast tipped forward and headstay attached to the bow. Lowering

the mast in this manner is dangerous even without a furler, and can be

further complicated by the weight of the furler and the sail.

“This product is intended for use only on sailboats having masts

fixed vertically in place at all times while the boat is in the water,

wherein the mast may only be lowered in accordance with the boat

manufacturer’s instructions when the boat is on land.

Any other

use of the product constitutes misuse, and may result in

damage to the product, and/or serious injury to the user.”

Summary of Contents for FLEXIBLE FURLER 2

Page 4: ... 2 ...