User’s Guide for Hydraulic Garage Jacks, model

YAK 40/Q

Warnings – Safe Usage Instructions

1.

This is a lifting device only.

2.

Do not move or transport the load while on the jack.

3.

The load must be supported immediately by axle stands.

4.

Do not overload. Overloading may cause damage to or failure of the jack.

5.

Lift only on areas as specified by the manufacturer. Make sure that the saddle cushion cannot slip

during lifting (Note: the saddle will describe a curve)

6.

This jack is designed for use only on hard level surfaces capable of sustaining the load. Use on

other than hard level surfaces may result in jack instability and possible loss of load.

7.

Point the wheels forward and apply the brake.

8.

No person should remain in, on, or get bodily under a load that is being jacked or is only supported

by a jack.

9.

The safety valve being adjusted and sealed by the manufacturer shall not be additionally adjusted.

10.

Do only apply options recommended. See “Options”.

11.

Failure to heed these warnings may result in loss of load, damage to jack, and/or failure resulting in

personal injury or property damage.

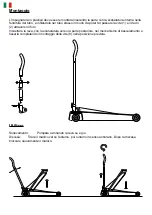

Assembly

Place the plastic handle with the inner groove in the slot of the lever tube and press it far into the tube to

mount screw (1) and nut (2) through transverse hole.

Push lever completely into the tipping gear with slot turning backward and fasten it by mounting screw (9)

completely into the slot.

Use of the jacktc “Use of the jack”

Lifting: Activate lever up and down.

Lowering:

Pull handle outward, then turn carefully counter clockwise. Turn handle back to locked

position after lowering.

Maintenancetc “Maintenance”

Daily: Inspect jack for damage.

Monthly: Oil all mechanical parts.

Yearly: Inspect for abnormal wear and tear and lubricate all mechanical part.

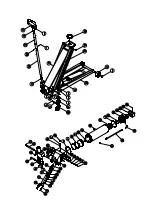

Refilling of oil: Pump and cylinder form a closed system and refilling of oil is only necessary in exceptional

cases. To check the oil level it is necessary to take out the pump, complete:

pump the jack half-way up.

keep the handle vertically and block the piston rod (35) in the inmost position by a screw or the like through

the hole in the release bracket. (44). Mind the inner spring.

Remove handle and tipping gear as well as two screws (8) on the top of the lifting frame.

Unfasten screw (26) and disconnect the piston rod and the base frame by lifting the lifting frame.

Lift the loose complete pump up and out of the lifting frame.

Correct oil level is up to lower edge of filling hole (28) keeping the complete pump vertically and the piston

rod pushed in. Too much oil might cause imperfect pump function.

Oil quantity: YAK 40/Q: 0,8l

Any good hydraulic oil of viscosity of 10°-32°cSt/40° can be used.

NEVER USE BRAKE NLUID.

Destruction

When the jack after several years is worn and must be dismantled, the oil must be drained off and legally

disposed of.