Page 13

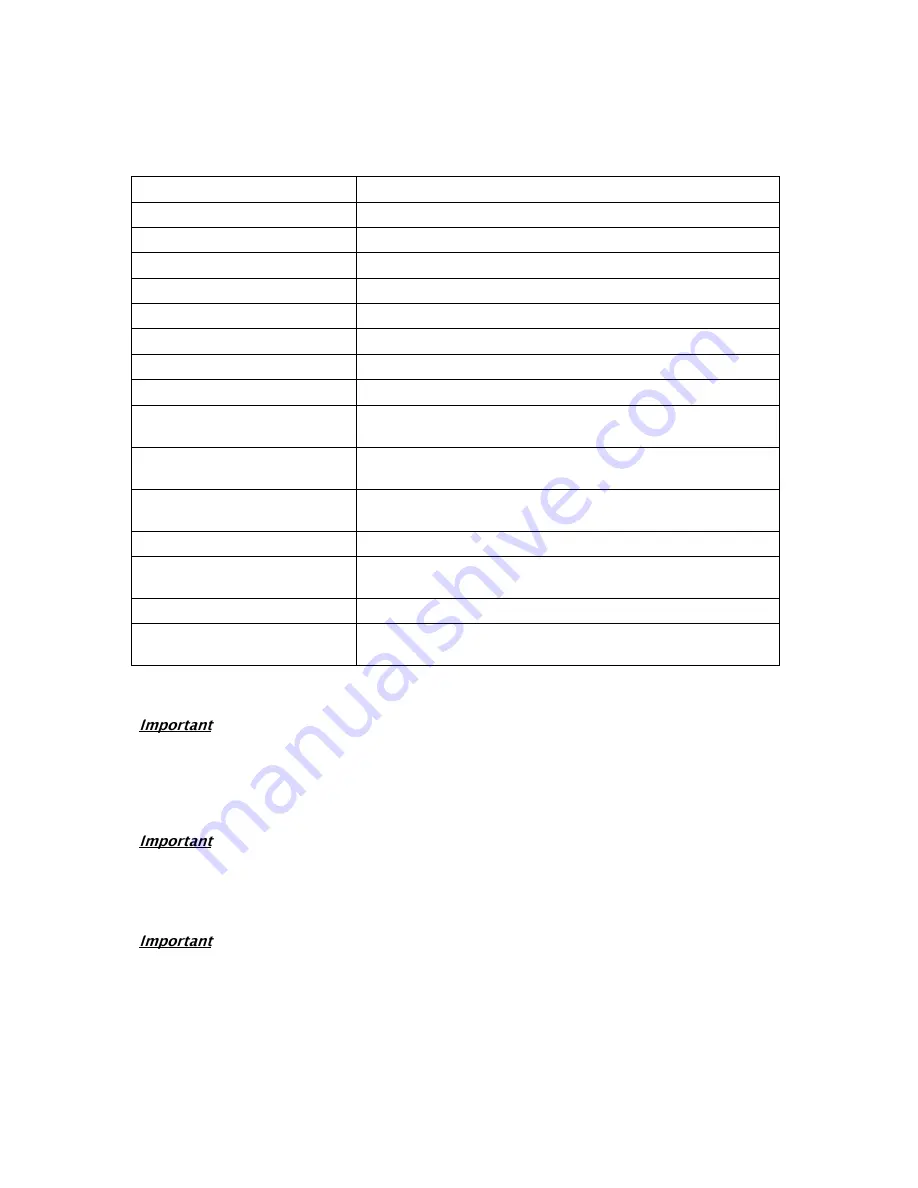

24 Business Cards to view, 85x54mm, (3 columns of 8) on an SRA3 sheet.

Top Margin 6mm

Business Card Height 54mm

Cross Cut Gutter 0mm

Mark registration

Action

Operation

Turn Zip21A on

Machine will initialise and display operating screen.

Press “Cutting Data”

Machine opens current job for editing

Press “Edit”

Edit button flashes and program settings can be adjusted

Press “Mark/Edge button”

Selects Lead Edge or Registration Mark

Press “No of cards button”

Displays a keypad, press 8 and then return arrow

Press “Margin button”

Displays a keypad, press 6 and then return arrow

Press “Card Length button”

Displays a keypad, press 54 and then return arrow

Press “Gutter Length button”

Displays a keypad, press 0 and then return arrow

Press “Last Cut Offset button”

This is normally set at -0.01

Displays a keypad, press selection and then return arrow

Press “Job Name button”

Displays a keypad, enter ZIP21A DEMO SHEET and then

return arrow

Press “Card Size button”

Displays a keypad, enter 85x54 MM 24 UP and then return

arrow

Press “ Edit”

Edit button stops flashing

Press “Save”

Dislay shows memory store locations. Select the location

required.

Press “Save” again

Screen returns to the editing screen

Press “ Main Page”

Returns to main operating screen with job recalled and

displayed

: The recommended trim off from the tail edge of the sheet is between 4mm – 10mm

(0.160" - 0.3937"). Tail edge trim off that is too long may hang up in the guillotine causing the

Zip21A to display an error. If this occurs, turn the power "OFF". Remove the top guard and

remove the tail edge trim off scrap. Assure that the recommended tail trim off dimension is

established when laying out the sheet prior to printing.

: The Zip21A paper handling rollers that convey the stock through the machine are

designed to handle a specific thickness of paper. If the paper is thicker or thinner, there may be

a slight difference in the programmable cut off length. If the paper is thicker, the cut off length

is usually longer. If the paper is thinner, the cut off length is usually shorter. After running the

first sheet, check the cut off size and make any adjustments required in the program.

: Due to the feed system of the Zip21A, the last card cut can sometimes be slightly

longer than the others. This is also affected by the thickness of the paper; the thicker the

paper, the bigger the difference. To overcome this adjust the ‘Last Cut Offset button’ to the

desired value.