TO DISMANTLE PUMP

FREQUENTLY ASKED QUESTIONS

‘’MOTOR DOES NOT START’’

Disconnect switch open; Fuses blown or thermal overload open;

Motor windings burned out; Defective starting switch inside motor;

Disconnected or defective wiring.

‘’MOTOR DOES NOT REACH FULL SPEED’’

Low voltage; Motor windings connected for wrong voltage; Shaft

binding or impeller rubbing.

‘’MOTOR OVERHEATS (Protector trips)’’

Low voltage; Motor windings connected for wrong voltage;

Inadequate ventilation.

‘’PUMP DELIVERS NO WATER’’

Pump not primed; Closed valve in suction or discharge line; Suction

or discharge line plugged; Leakage of air into suction system; Impeller

plugged.

‘’LOW PUMP CAPACITY’’

Check setting of dial valve; Valve in suction or discharge line partly closed;

Suction or discharge line partly plugged; Suction or discharge line too

small; Pump running at reduced speed (see above); Plugged basket in

skimmer or hair in lint strainer; Dirty filter; Impeller plugged.

‘’LOW PUMP PRESSURE’’

Check setting of dial valve; Pump running at reduced speed (see

above); Discharge valve or inlet fitting opened too much; Leakage of air

into suction system.

‘’HIGH PUMP PRESSURE’’

Discharge valve or inlet fittings closed too much; Return lines too small;

Dirty filter.

‘’NOISY PUMP AND MOTOR’’

Plugged basket in skimmer or hair in lint strainer; Defective motor

bearings; Valve in suction line partly closed; Suction line partly plugged;

Vacuum cleaner hose plugged or too small; Piping causing strain on

pump case; Impeller rubbing on pump case.

‘’LEAKAGE OF WATER AT SHAFT’’

Shaft seal requires replacement.

‘’AIR BUBBLES AT INLET FITTINGS’’

Leakage of air into suction line at connections; Cover of hair and lint

strainer not airtight; Restriction in suction line; Low water level in pool.

M22904240

WWW.CARVINPOOL.COM

4

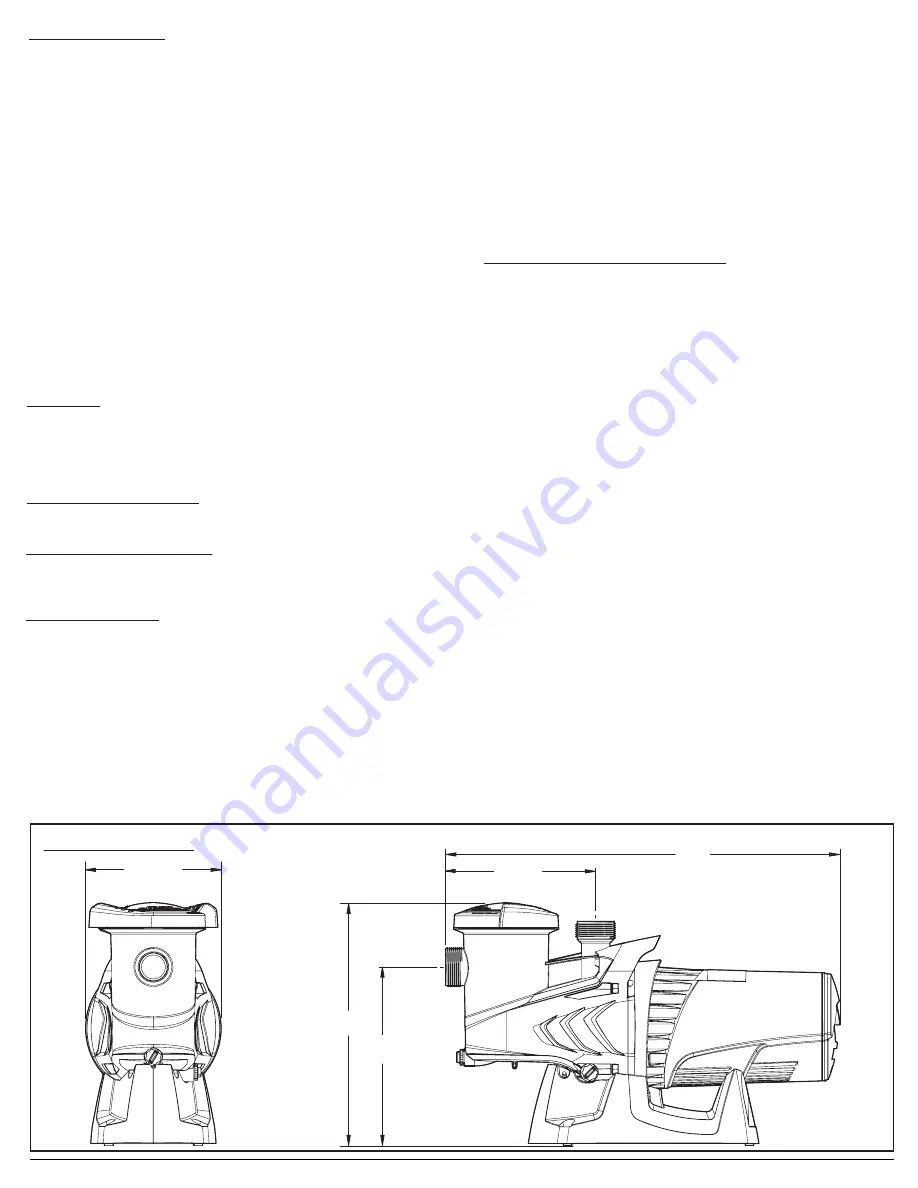

Dimensionnal

(Fig.1)

NOTE: VERIFY THE ELECTRICAL POWER IS DISCONNECTED BEFORE YOU

CONTINUE. Note: Numbers in brackets refer to item numbers in Figure 5.

1). Remove the back plate (19) by taking out two self-tapping screws (17).

2). Disconnect the black wire (30) from the switch (18).

3). Disassemble base(23) blocking the rotation of the splash cover. Turn

the Splash Cover counterclockwise to unlock (see Figure 3).

4).

THE FOLLOWING IS FOR U.S. 2 SPEED SHARKJET PUMP ONLY:

To facilitate access to the motor shaft remove the motor cap screw and

remove back cap. It is not necessary to unplug the motor power cord (29),

unless the motor (15) or the power cord (23) have to be replaced or

repaired.

5). Remove the four screws (13) that holds the pump together, retract the

sub-assembly containing: Motor Bracket ( 12), Main O-Ring (11), Motor

(15), Mechanical Shaft Seal Assy (10), Flinger (14), Impeller (9), Diffuser (7)

and Diffuser O-Ring(6)

6). To disassemble Diffuser (7), insert a small flat screwdriver between the

two small snaps on Motor Bracket (12), gently lift the diffuser assembly

tab and pull the diffuser to free one side at a time. (See Figure 4).

7). Bloc the motor shaft by inserting a flat screwdriver in the slot in the end

of the shaft at the back of the motor, and unscrew the impeller.

8). Remove the four long motor screws holding the motor (15) to the

bracket (12).

INSPECTION

Inspect all parts of the pump for wear or damage, and order replacements

as necessary. Check the shaft seal (10) carefully. Look for cracks in the

ceramic seat. Check the seal faces for wear and nicks. Flex the rubber parts

and check them for holes and cracks. Replace the complete seal if any part

is damaged, or if the seal leaks. Do not use old parts.

SHAFT SEAL REPLACEMENT

Take great care while handling the shaft seal (10) to avoid damage to

its carbon and ceramic sealing faces.

TO REMOVE OLD SHAFT SEAL

After dismantling the pump and removing the impeller as already

described, pull the rotating parts of the seal from the hub of the impeller

(9). Press or tap the stationary section of the seal from the motor bracket

FIT NEW SHAFT SEAL

DO NOT USE OIL OR GREASE ON THE SEAL PARTS,

because either may

damage the thermoplastic material of the pump through overheating

or chemical reaction. Make sure that the pump parts are clean, but be

careful not to scratch the surfaces that come into contact with the seal.

Moisten the rubber cup of the new stationary section with WATER.

Protect the sealing surface with a disc of clean cardboard, and use a

light mallet and small wooden block to tap the seal gently into the

bracket (12). Be sure that the sealing surface faces the pump. Reassem-

ble the bracket (12) onto the motor (15). Moisten the bore of the new

rotating seal assembly with WATER. Push the assembly into position on

the hub of the impeller (9) with its sealing surface facing outward.

Prevent the motor shaft from rotating by inserting a screwdriver in the

screw the impeller (9) to the shaft by hand. Put the diffuser back into

place by snapping the Motor Bracket (12) and the diffuser (7) back

together . Make sure that the diffuser o-ring (6) is still on. Make sure

that the Main O-Ring (11) is properly positioned on the face of the

Motor Bracket (12), then reassemble the bracket (12) to the pump Strain-

er Case(5). Tighten the screws (13) evenly by tightening its opposit

in alternance. Reassemble the splash cover (20) and the base (23) (Fig. 3).

Reinstall the pump and run it for 5 minutes to ensure that no water leaks

from the pump case (which would indicate improper seal installation). If

any water is observed leaking from the pump case, repeat seal installation

procedure.

8 “ (21.27 cm)

3

8

/

24 “

(62.62 cm)

21

32

/

9 “

(24.45 cm)

3

8

/

15 “

(38.48cm)

9

64

/

11 “

(28.30cm)

9

64

/