17

CABINET MAINTENANCE

CASTERS

Caster bearings are equipped with Zerk grease fittings so that they

may be easily lubricated with a grease gun. Lubricate bearings at

least once every six months.

REPLACING THE DOOR GASKET

1. Remove the screws located under the gasket on the cabinet.

2.

Remove the gasket and discard.

3.

Install the new gasket and replace the screws.

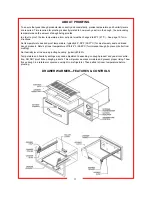

REVERSING THE DOOR

Reversing the door takes about 30 minutes & requires two people.

1. Using a small screwdriver, pry off the hinge covers and set

aside. Removing the covers will allow access to the inside

hinge screws. Remove the three screws that hold each hinge

to the cabinet. DO NOT REMOVE THE SCREWS THAT

HOLD THE HINGES TO THE DOOR. Remove the door, tak-

ing care not to let it fall.

2. Remove the door strike plate and screws adjacent to the door

opening on the cabinet. Reinstall door strike plate and screws

on opposite side of the cabinet.

3. Screw hinges onto opposite side of the door.

4. With the help of another person, hold door up to the cabinet

and attach with the screws removed in step one. Before tight-

ening the screws, be sure the door is flush, level and square.

Replace the hinge covers.

WARNING:

DO NOT perform

these procedures

while the cabinet is turned on

or heated. Turn off the power

and wait for the cabinet to cool

to room temperature.

CAUTION:

Do not move cabinet

unless door is secure-

ly closed. Serious damage to

hinges and door may result if

bumped into tables, walls, or

other equipment when the

doors are open.