43

Remote on-off control

Remote on-off control may be applied by hard-wired con-

nection (see Controls and Troubleshooting literature) or by

connection to a Carrier Comfort Network

®

(CCN) system.

Optional hydronic system selection

Select pump gpm from resulting chiller selection and total

pressure loss in the system plus the chiller internal pressure

loss.

NOTE: Maximum gpm (L/s), pressure and pump hp must

not exceed maximum on pump curve.

Pump flow can be reduced using factory-supplied balanc-

ing valve up to 10%. Beyond that, impeller trimming is rec-

ommended to reduce energy consumption. Contact your

Carrier representative for specific amount of trim required.

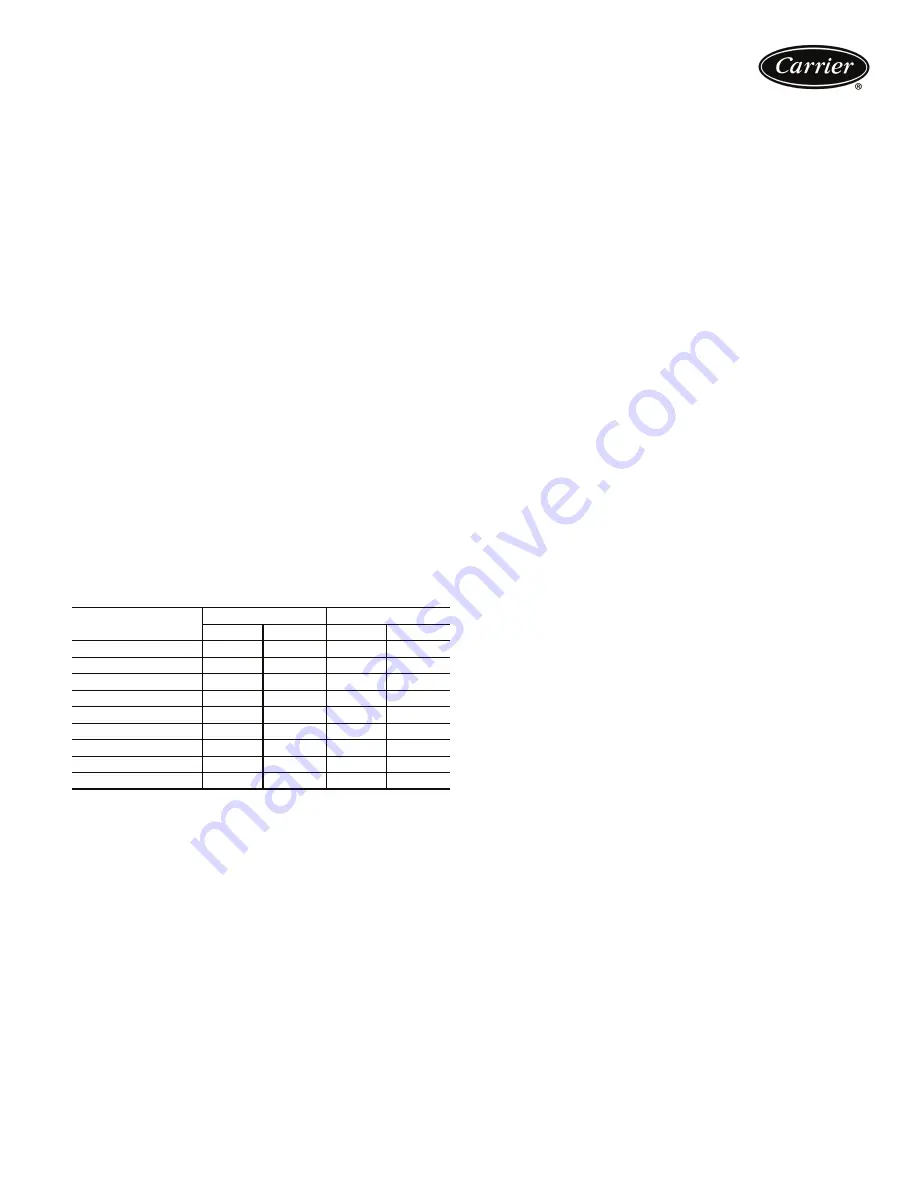

Expansion tank supplied will allow loop expansion due

to ambient fluctuations for loop volumes of up to the values

in the table below. If loop volume exceeds the maximum

loop volume, a larger expansion tank must be field

supplied.

The supplied expansion tanks have the following specifi-

cations: 30RA010-030 — 5.0 total gal., 2.4 gal. accep-

tance volume, 30RA035-055 — 10.0 total gal., 5.5 gal.

acceptance volume.

Maximum loop volume is based on typical system pres-

sure of 12 psig (83 kPa) and 30 psig (207 kPa) of mini-

mum and maximum pressures, and 100 F (37.8 C) mean

temperature.

MAXIMUM LOOP VOLUME

LEGEND

Parallel chillers with hydronic packages require that pump

inlets be equalized to prevent pump cavitation. Pump

expansion tanks must be removed and located together in

the common pump suction header. All materials needed

for expansion tank relocation are field supplied. Appropri-

ate measures must be taken for freeze protection.

Air separation

For proper system operation, it is essential that water

loops be installed with proper means to manage air in the

system. Free air in the system can cause noise, reduce ter-

minal output, stop flow, or even cause pump failure due to

pump cavitation. For closed systems, equipment should be

provided to eliminate all air from the system.

The amount of air that water can hold in solution depends

on the pressure and temperature of the water/air mixture.

Air is less soluble at higher temperatures and at lower pres-

sures. Therefore, separation can best be done at the point

of highest water temperature and lowest pressure. Typical-

ly, this point would be on the suction side of the pump as

the water is returning from the system or terminals. Gener-

ally speaking, this is the best place to install an air separa-

tor, if possible.

1. Install automatic air vents at all high points in the sys-

tem. (If the 30RA unit is located at the high point of

the system, a vent can be installed on the piping

entering the heat exchanger on the ¼-in. NPT female

port.)

2. Install an air separator in the water loop, at the place

where the water is at higher temperatures and lower

pressures — usually in the chilled water return piping.

On a primary-secondary system, the highest tempera-

ture water is normally in the secondary loop, close to

the decoupler. Preference should be given to that

point on the system. In-line or centrifugal air separa-

tors are readily available in the field.

It may not be possible to install air separators at the place

of lowest pressure and highest temperature. In such cases,

preference should be given to the points of highest

temperature. It is important that pipe be sized correctly so

that free air can be moved to the point of separation. Gen-

erally, a water velocity of at least 2 ft per second (0.6 m

per second) will keep free air entrained and prevent it from

forming air pockets.

Automatic vents should be installed at all physically elevat-

ed points in the system so that air can be eliminated during

system operation. Provision should also be made for man-

ual venting during the water loop fill. It is important that

the automatic vents be located in accessible locations for

maintenance purposes, and that they be located where

they can be prevented from freezing.

Minimum time to power chiller before

start-up

In order to ensure that the crankcase heaters are provided

sufficient time to raise the crankcase temperature to the

required operating point, power must be applied to the

chiller and the compressor circuit breakers must be on a

minimum of 24 hours prior to chiller start-up.

CONCENTRATION

30RA010-030

30RA035-055

GAL.

L

GAL.

L

PURE WATER

310

1173

725

2744

10% EG

180

681

425

1609

20% EG

175

662

410

1552

30% EG

155

587

370

1401

40% EG

150

568

350

1325

10% PG

175

662

410

1552

20% PG

150

568

350

1325

30% PG

128

485

300

1136

40% PG

118

447

275

1041

EG —

Ethlyene Glycol

PG —

Propylene Glycol