42

Multiple chillers

Where chiller capacities greater than 55 tons (180 kW) are

required, or where standby capability is desired, chillers

may be installed in parallel. The flow must be balanced

according to the recommendations for each chiller.

Where applied in parallel with optional hydronic pack-

age, expansion tank must be disconnected and a single

expansion tank must be installed in the system.

Unit software is capable of controlling two units as a sin-

gle plant. Refer to Controls, Start-Up, Operation, Service,

and Troubleshooting guide for further details. Hydronic

pump package may not be applied in series applications.

Condenser coil protection (

Enviro-Shield

™)

Refer to the Environmental Corrosion Protection white

paper for more information.

Pre-coated aluminum-fin coils

have a durable epoxy-

phenolic coating applied to the fin prior to the fin stamping

process to provide protection in mildly corrosive coastal

environments. Pre-coated coils have an inert barrier

between the aluminum fin and copper tube. This barrier

electrically disconnects the dissimilar metals to minimize

the potential for galvanic corrosion. This economical

option provides substantial corrosion protection beyond

the standard uncoated coil construction.

Copper-fin coils

provide increased corrosion resistance

in moderate coastal environments where industrial air pol-

lution is not present. All-copper coils eliminate bimetallic

construction to eliminate the potential for galvanic corro-

sion. Application in industrial environments is not recom-

mended due to potential attack from sulfur, sulfur oxide,

nitrogen oxides, carbon and several other industrial air-

borne contaminants. In moderate seacoast environments,

copper-fin coils have extended life compared to standard

or pre-coated aluminum-fin coils.

E-coated aluminum-fin coils

have an extremely flexible

and durable epoxy coating uniformly applied to all coil

surfaces. Unlike brittle phenolic dip and bake coatings,

e-coat provides superior protection with unmatched flexi-

bility, edge coverage, metal adhesion, thermal perfor-

mance and most importantly, corrosion resistance.

E-coated coils provide this protection since all coil surfaces

are completely encapsulated from environmental contami-

nation. Specify e-coated aluminum-fin coils for industrial

environments with high levels of air pollution. This option

also provides better protection compared to standard or

pre-coated aluminum-fin coils in industrial environments.

E-coated copper-fin coils

have the same flexible and

durable epoxy coating as e-coated aluminum-fin coils.

However, this option combines the natural salt and envi-

ronmental resistance of all-copper construction with the

highest level of corrosion protection. Specify e-coated

copper-fin coils in the harshest combination of coastal and

industrial environments.

Electrical/utility interests

Energy management —

Use of energy management

practices can significantly reduce operating costs, espe-

cially during off-peak modes of operation. Demand limiting

and temperature reset are 2 techniques for accomplishing

efficient energy management. See Demand Limiting (also

called load shedding) section on this page for further

details.

Demand limiting (load shedding)

When a utility’s demand for electricity exceeds a certain

level, loads are shed to keep electricity demand below a

prescribed maximum level. Typically, this happens on hot

days when air conditioning is most needed. The energy

management module (EMM) can be added to accomplish

this reduction. Demand may be limited on unit by resetting

fluid temperature, or by unloading the chiller to a given

predetermined percentage of the load. Demand limit may

also be driven by an external 4 to 20 mA signal. These fea-

tures require a signal from an intelligent central control. Do

not cycle demand limiter for less than 10 minutes on and

5 minutes off. Duty cycling cycles electrical loads at regular

intervals regardless of need. This reduces the electrical

operating costs of building by “fooling” demand indicating

devices. Duty cycling of compressors or fans is not recom-

mended since motor winding and bearing life will suffer

from constant cycling.

Application data (cont)

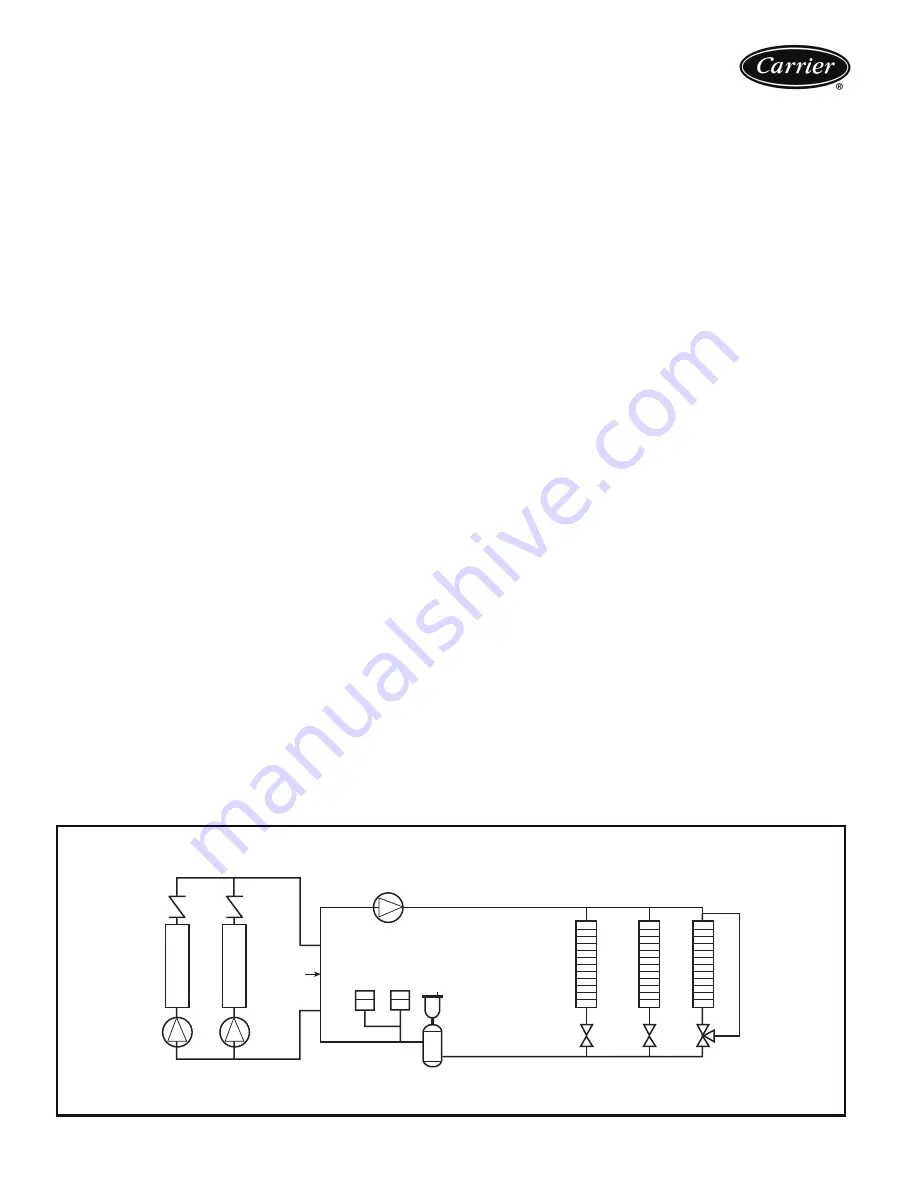

TYPICAL MULTIPLE CHILLER CONFIGURATION WITH AIR ELIMINATOR AND EXPANSION TANK LOCATION

Distri

b

ution Pump

Expansion

Tank(s)

Air Separator

with Vent

Decoupler

Chiller 1

Chiller 2

Zone 1

Zone 2

Zone 3