4

1 - INTRODUCTION

Prior to the initial start-up of the 30RW/30RWA units, the

people involved in the on-site installation, start-up, operation

and maintenance of this unit should be thoroughly familiar

with these instructions and the specific project data for the

installation site.

The 30RW/30RWA liquid chillers are designed to provide a

very high level of safety during installation, start-up, opera-

tion and maintenance. They will provide safe and reliable

service when operated within their application range.

This manual provides the necessary information to fami-

liarize yourself with the control system before performing

start-up procedures. The procedures in this manual are

arranged in the sequence required for machine installation,

start-up, operation and maintenance.

Be sure you understand and follow the procedures and

safety precautions contained in the instructions supplied

with the machine, as well as those listed in this guide.

To find out, if these products comply with European

directives (machine safety, low voltage, electromagnetic

compatibility, equipment under pressure etc.) check the

declarations of conformity for these products.

1.1 - Installation safety considerations

After the unit has been received, when it is ready to be

installed or reinstalled, and before it is started up, it must be

inspected for damage. Check that the refrigerant circuit(s)

is (are) intact, especially that no components or pipes have

shifted (e.g. following a shock). If in doubt, carry out a leak

tightness check and verify with the manufacturer that the

circuit integrity has not been impaired. If damage is detected

upon receipt, immediately file a claim with the shipping

company.

Do not remove the skid or the packaging until the unit is

in its final position. These units can be moved with a fork

lift truck, as long as the forks are positioned in the right

place and direction on the unit.

The units can also be lifted with slings, using only the

designated lifting points marked on the unit.

These units are not designed to be lifted from above. Use

slings with the correct capacity, and always follow the

lifting instructions on the certified drawings supplied with

the unit.

Safety is only guaranteed, if these instructions are carefully

followed. If this is not the case, there is a risk of material

deterioration and injuries to personnel.

DO NOT COVER ANY PROTECTION DEVICES.

This applies to fuse plugs and safety valves (if used) in the

refrigerant or heat transfer medium circuits. Check if the

original protection plugs are still present at the valve outlets.

These plugs are generally made of plastic and should not be

used. If they are still present, please remove them. Install

devices at the valve outlets or drain piping that prevent the

penetration of foreign bodies (dust, building debris, etc.) and

atmospheric agents (water can form rust or ice). These

devices, as well as the drain piping, must not impair

operation and not lead to a pressure drop that is higher

than 10% of the control pressure.

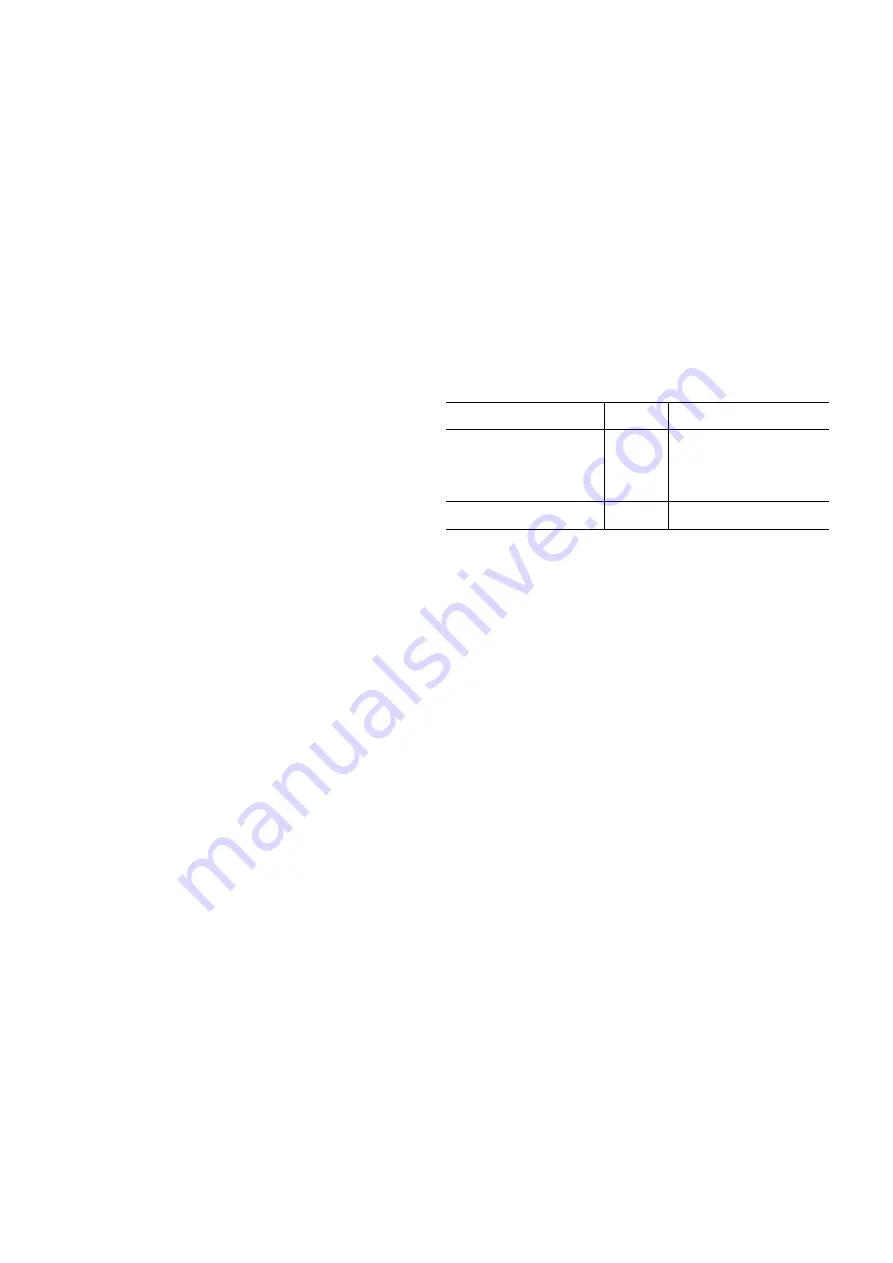

Classification and control

In accordance with the Pressure Equipment Directive and

national usage monitoring regulations in the European

Union the protection devices for these machines are

classified as follows:

Safety

accessory*

Damage limitation accessory**

in case of an external fire

Refrigerant side

High-pressure switch

x

External relief valve***

x

Rupture disk

x

Fuse plug

x

Heat transfer fluid side

External relief valve****

x

x

* Classified for protection in normal service situations.

** Classified for protection in abnormal service situations.

*** The instantaneous over-pressure limited to 10% of the operating pressure

does not apply to this abnormal service situation. The control pressure can be

higher than the service pressure. In this case either the design temperature or

the high-pressure switch ensures that the service pressure is not exceeded in

normal service situations.

**** The classification of these safety valves must be made by the personnel that

completes the whole hydronic installation.

Do not remove these valves and fuses, even if the fire risk

is under control for a particular installation. There is no

guarantee that the accessories are re-installed if the instal-

lation is changed or for transport with a gas charge.

All factory-installed safety valves are lead-sealed to

prevent any calibration change. If the safety valves are

installed on a reversing valve (change-over), this is

equipped with a safety valve on each of the two outlets.

Only one of the two safety valves is in operation, the other

one is isolated. Never leave the reversing valve in the

intermediate position, i.e. with both ways open (locate the

control element in the stop position). If a safety stop is

removed for checking or replacement please ensure that

there is always an active safety stop on each of the reversing

valves installed in the unit.

The external safety valves must always be connected to

drain pipes for units installed in a closed room. Refer to

the installation regulations, for example those of European

standard EN 378 and EN 13136.

These pipes must be installed in a way that ensures that

people and property are not exposed to refrigerant leaks.

As the fluids can be diffused in the air, ensure that the

outlet is far away from any building air intake, or that

they are discharged in a quantity that is appropriate for a

suitably absorbing environment.