between the thermostat and the unit. If the thermostat is located

more than 100 ft. from the unit (as measured along the control

voltage wires), use no. 16 AWG color-coded, insulated (35 C

minimum) wires.

STANDARD CONNECTION

Remove knockout hole located in the electric heat panel adjacent

to the control access panel. See Fig. 2 & 3. Remove the rubber

grommet from the installer’s packet (included with unit) and install

grommet in the knockout opening. Provide a drip loop before

running wire through panel.

Run the low-voltage leads from the thermostat, through the inlet

hole, and into unit low-voltage splice box.

Locate five 18-gage wires leaving control box. These low-voltage

connection leads can be identified by the colors red, green, yellow,

brown, and white (See Fig. 10). Ensure the leads are long enough

to be routed into the low-voltage splice box (located below right

side of control box). Stripped yellow wire is located in connection

box. Route leads through hole in bottom of control box and make

low-voltage connections (See Fig. 10). Secure all cut wires, so that

they do not interfere with operation of unit.

TRANSFORMER PROTECTION

The

transformer

is of the energy-limiting type. It is set to

withstand a 30-second overload or shorted secondary condition.

PRE-START-UP

FIRE, EXPLOSION, ELECTRICAL SHOCK HAZARD

Failure to observe the following warnings could result in

serious personal injury:

1. Follow recognized safety practices and wear protective

goggles when checking or servicing refrigerant system.

2. Relieve and recover all refrigerant from system before

touching or disturbing anything inside terminal box if

refrigerant leak is suspected around compressor terminals.

3. Never attempt to repair soldered connection while refrig-

erant system is under pressure.

4. Do not use torch to remove any component. System

contains oil and refrigerant under pressure. To remove a

component, wear protective goggles and proceed as fol-

lows:

a. Shut off electrical power to unit.

b. Relieve and reclaim all refrigerant from system using

both high- and low-pressure ports.

c. Cut component connecting tubing with tubing cutter and

remove component from unit.

d. Carefully unsweat remaining tubing stubs when neces-

sary. Oil can ignite when exposed to torch flame.

Proceed as follows to inspect and prepare the unit for initial

startup:

1. Remove access panel.

2. Read and follow instructions on all WARNING, CAUTION,

and INFORMATION labels attached to, or shipped with, unit.

3. Make the following inspections:

a. Inspect for shipping and handling damages such as broken

lines, loose parts, disconnected wires, etc.

b. Inspect for oil at all refrigerant tubing connections and on

unit base. Detecting oil generally indicates a refrigerant

leak. Leak test all refrigerant tubing connections using

electronic leak detector, halide torch, or liquid-soap solu-

tion. If a refrigerant leak is detected, see Check for

Refrigerant Leaks section.

c. Inspect all field- and factory-wiring connections. Be sure

that connections are completed and tight.

d. Ensure electrical wiring does not contact refrigerant tubes

or sharp metal edges.

e. Inspect coil fins. If damaged during shipping and handling,

carefully straighten fins with a fin comb.

Verify the following conditions:

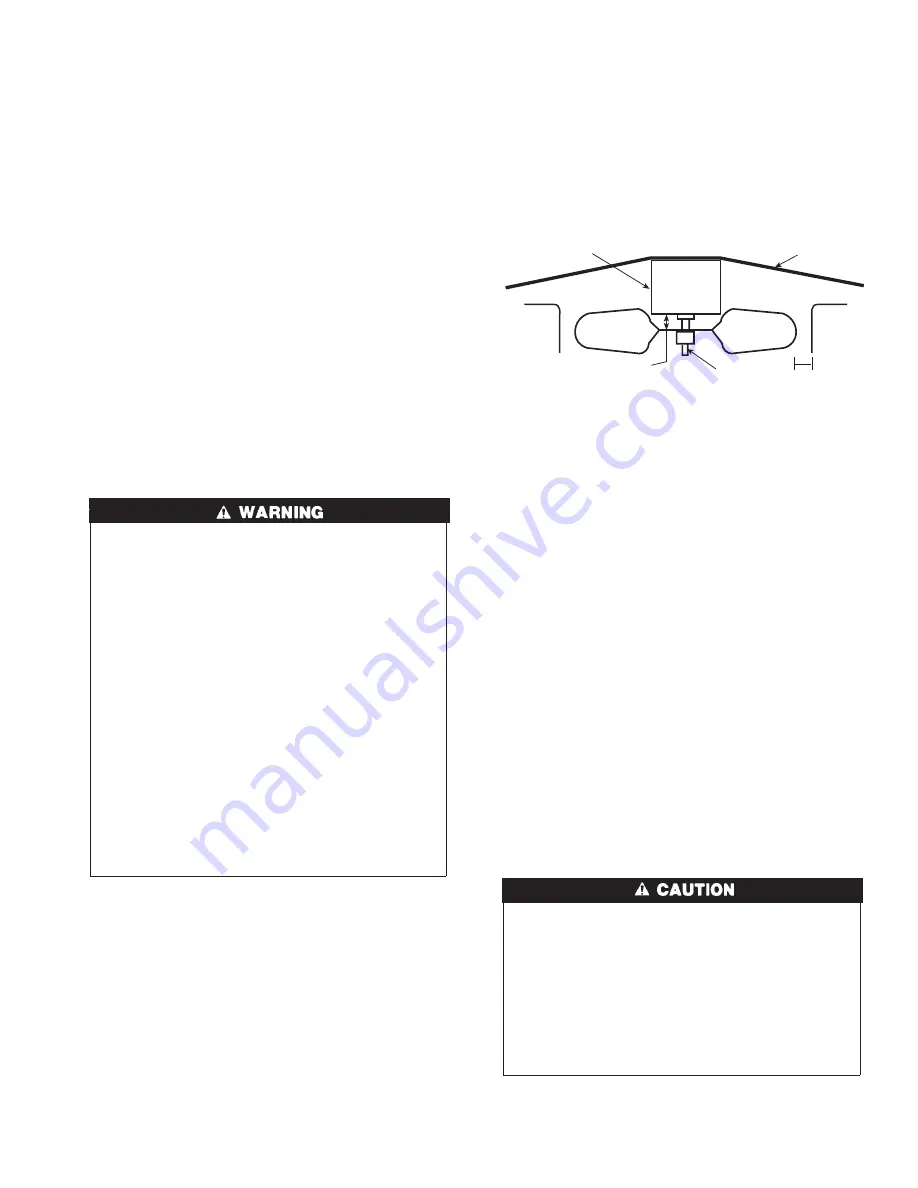

a. Make sure that condenser-fan blade is correctly positioned

in fan orifice. Leading edge of condenser-fan blade should

be 1/2 in. maximum from fan orifice (See Fig. 11).

b. Make sure that air filter(s) is in place.

c. Make sure that condensate drain trap is filled with water to

ensure proper drainage.

d. Make sure that all tools and miscellaneous loose parts have

been removed.

START-UP

CHECK FOR REFRIGERANT LEAKS

Proceed as follows to locate and repair a refrigerant leak and to

charge the unit:

1. Locate leak and make sure that refrigerant system pressure has

been relieved and reclaimed from both high- and low-pressure

ports.

2. Repair leak following accepted practices. NOTE: Install a

filter drier whenever the system has been opened for repair.

3. Add a small charge of R-22 refrigerant vapor to system and

leak-test unit.

4. Recover refrigerant from refrigerant system and evacuate to

500 microns if no additional leaks are not found.

5. Charge unit with R-22 refrigerant, using a volumetric-

charging cylinder or accurate scale.

Refer to unit rating plate

for required charge.

Be sure to add extra refrigerant to

compensate for internal volume of filter drier.

START UP COOLING SECTION AND MAKE ADJUST-

MENTS

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in unit component

damage.

Complete the required procedures given in the Pre-Start- Up

section before starting the unit. Do not jumper any safety

devices when operating the unit. Do not operate the compres-

sor when the outdoor temperature is below 40°F (unless

accessory low-ambient kit is installed). Do not rapid-cycle the

compressor. Allow 5 minutes between “on” cycles to prevent

compressor damage.

CHECKING COOLING CONTROL OPERATION

Start and check the unit for proper cooling control operation as

follows:

Fig. 11—Fan Blade Clearance

C99009

FAN GRILLE

MOTOR

1/8" MAX BETWEEN

MOTOR AND FAN HUB

MOTOR SHAFT

1/2˝

11