50

Failure to provide proper water quality will void the fan

coils unit's warranty.

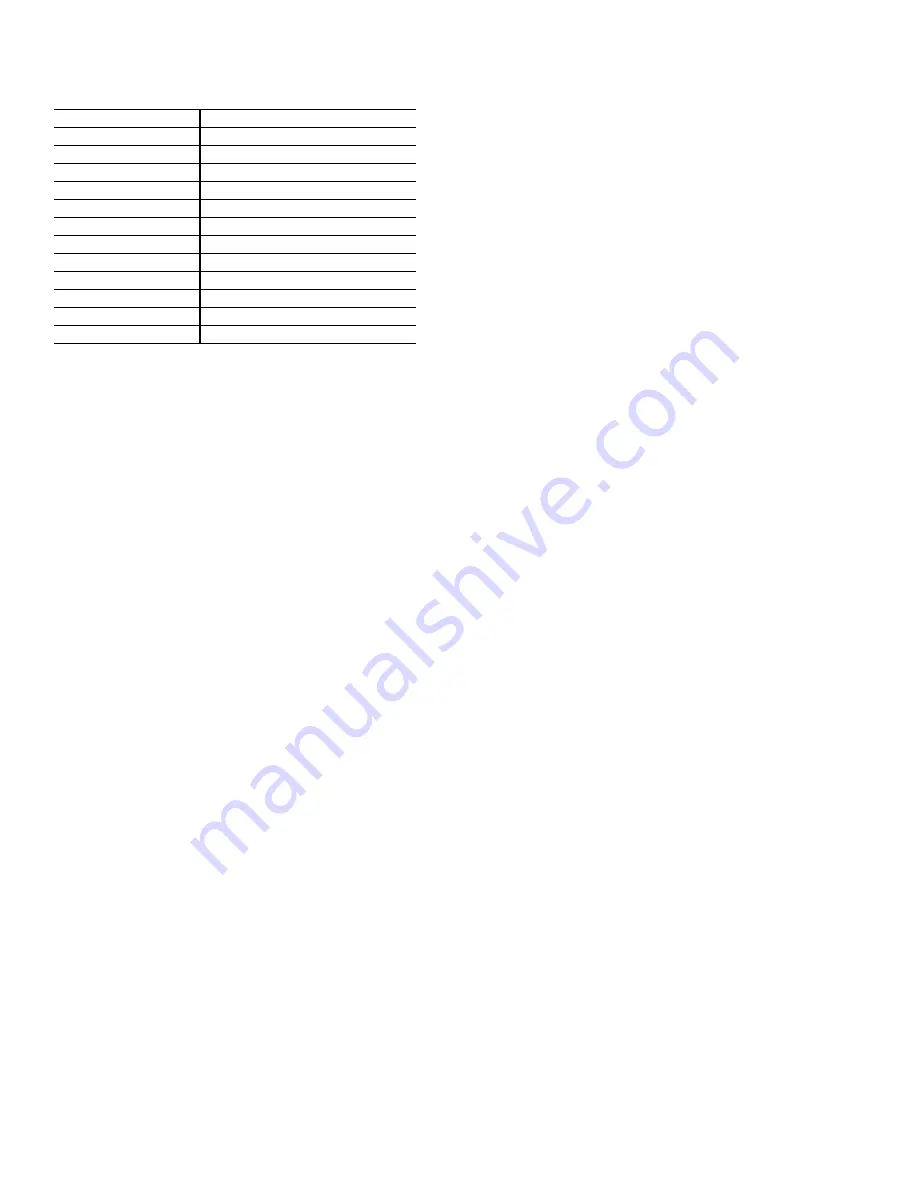

Table 6 — Water Quality Concentrations

Controls Operation —

Before proper control operation

can be verified, all other systems must be operating properly.

The correct water and air temperatures must be present for the

control function being tested. Some controls and features are

designed to not operate under certain conditions. For example,

on a two-pipe cooling/heating system with auxiliary electric

heat, the electric heater cannot be energized with hot water in

the system.

A wide range of controls, electrical options and accessories

may be used with the equipment covered in this manual. Con-

sult the approved unit submittals, order acknowledgments, and

other literature for detailed information regarding each individ-

ual unit and its controls. Since controls and features may vary

from one unit to another, care should be taken to identify the

controls used on each unit and their proper control sequence.

Information provided by component manufacturers regarding

installation, operation, and maintenance of their individual con-

trols is available upon request.

When changing from one mode to another (cooling to heat-

ing or heating to cooling), it may take some time to actually no-

tice a change in the leaving air temperature. In addition, some

units may be designed for a very low air temperature rise in

heating. Before declaring a unit inoperative or a component

defective, it may be necessary to verify operation by more than

one method.

SERVICE

Excessive Condensation on Unit —

Running

chilled water through a fan coil unit with the unit fan off can

cause excessive condensation. If fan cycling is used, a water

flow control valve should be installed to shut off the water

when the fan stops.

Other methods of control that avoid condensation problems

are as follows:

1. Continuous fan operation with motorized chilled water

valve controlled by a thermostat.

2. Continuous fan operation with thermostat control to

switch fan from high to low speed (instead of off).

To Clean Coil

1. Be sure electrical service switch is open, locked, and

tagged while working on unit.

2. Remove return-air grille access panel and brush between

coil fins with stiff wire brush. Care should be taken to not

damage coil fins. Follow-up by cleaning with vacuum

cleaner. If coil is cleaned with air hose and nozzle, take

care not to drive dirt and dust into other components.

Blow air through the coil fins from the leaving air face.

This should again be followed by vacuuming. Units

provided with the proper type of air filters, replaced regu-

larly, will require less frequent coil cleaning.

3. Install clean filter. Refer to Clean or Replace Air Filters

section.

Drain —

The drain must be checked before initial start-up

and at the beginning of each cooling season to assure that the

drain trap and line are clear. If it is clogged, take steps to clear

the debris so that condensate will flow easily.

Make periodic checks of the drain during the cooling season

to maintain a free flowing condensate. Units provided with sec-

ondary or tell-tale drain connection will indicate a clogged

main line by flow from the tell-tale connection.

NOTE: Should the growth of algae and/or bacteria be a con-

cern, consult an air conditioning and refrigeration supply orga-

nization familiar with local conditions for chemical or other

solution available to control these growths.

Check Drain —

Lock open and tag unit electrical service

switch.

Check drain pan, drain line and trap before initial start-up

and at start of each cooling season. A standard type pipe clean-

er for

3

/

4

-in. ID pipe can be used to ensure that pipe is clear of

obstruction so that condensate is carried away. Check the drain

line at filter cleaning time during the cooling season. Be sure

that debris has not fallen into unit through supply-air grille.

Should the growth of algae and/or bacteria be a concern, con-

sult an air conditioning and refrigeration supply organization

familiar with local conditions for chemicals or other solutions

available to control these agents.

Fan Motor Bearings —

Lock open and tag unit electri-

cal service switch.

Standard motors are permanently sealed and lubricated. No

lubrication is required unless special motors have been

supplied or unusual operating conditions exist.

Clean Fan Wheel —

Lock open and tag unit electrical

service switch.

For access to fan assembly, remove front or bottom panel.

Fan assembly may be removed from its tracks if unit has a long

conduit lead. Dirt and debris should not be allowed to accumu-

late on the blower wheel or housing. This can result in an un-

balanced blower wheel condition which can damage a blower

wheel or motor. The wheel and housing may be cleaned peri-

odically using a vacuum cleaner and a brush, taking care not to

dislodge the factory balancing weights on the blower wheel

blades.

Clean Electric Heater —

Lock open and tag unit elec-

trical service switch.

1. Remove dust, dirt, or foreign material before start-up. Do

not block normal airflow to and from units; blockage may

damage electric heaters.

2. Clean heater elements with soft brush or vacuum cleaner

as necessary.

3. To replace blown fusible links (nichrome heaters only):

a. Remove fan deck (horizontal units only) for

access to heater.

b. Remove nut securing link at each end; install new

link; reinstall nuts.

c. Reinstall fan deck (if removed).

Electric resistance heaters typically require no normal

periodic maintenance when unit air filters are changed

properly. The operation and service life may be affected by

other conditions and equipment in the system. The two most

important operating conditions for an electric heater are proper

airflow and proper supply voltage. High supply voltage and/or

poorly distributed or insufficient airflow over the element will

WATER CONTAINING

REQUIRED CONCENTRATION

Sulphate

Less than 200 ppm

pH

7.0 to 8.5

Chlorides

Less than 200 ppm

Nitrate

Less than 100 ppm

Iron

Less than 4.5 mg/l

Ammonia

Less than 2.0 mg/l

Manganese

Less than 0.1 mg/l

Dissolved Solids

Less than 1000 mg/l

CaCO3 Hardness

300 to 500 ppm

CaCO3 Alkalinity

300 to 500 ppm

Particulate Quantity

Less than 10 ppm

Particulate Size

800 micron max