Maintenance and Troubleshooting

AA2204_en | 2012-07-27

3–21

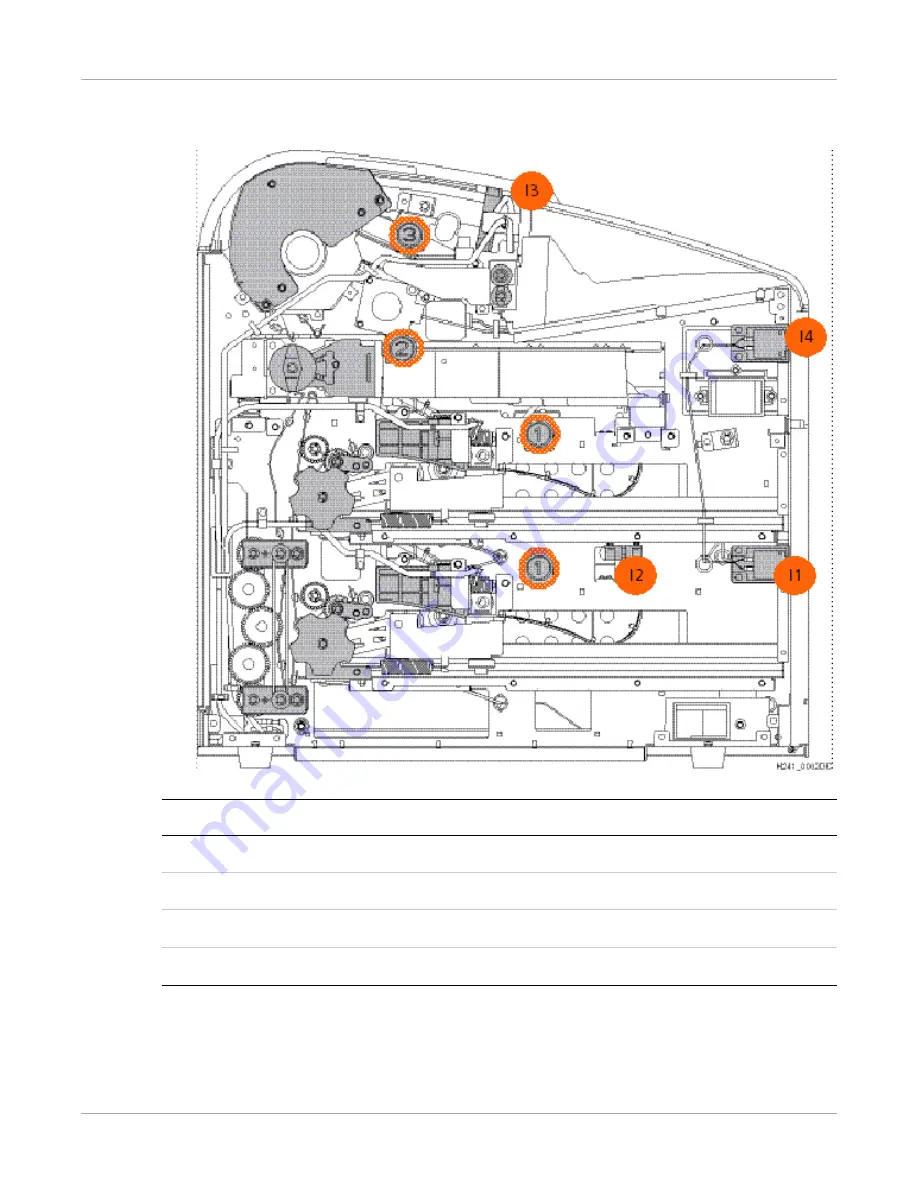

Figure 5:

Film Jam Areas

Jam Areas

Description

Interlocks

Description

1

Upper and Lower film supply

I1

Lower film supply

2

Film path

I2

Left cover

3

Processor / densitometer

I3

Top cover

I4

Upper film supply

SHORT TERM CONFIDENTIAL