E

CLIPSE

Service

Manual

Carefree of Colorado

10

052547-301r10

R

EPLACING THE

G

AS

S

HOCK

CAUTION

The gas shock has approximately 85 lbs. of pressure in the closed position. A

pressurized shock can open rapidly when removed or released causing personal injury and property

damage.

1. Open the awning.

NOTE:

The arm may not completely open when the shock has lost pressure or it is removed. It may be

necessary to pull the arm out and away from the vehicle to open the awning.

2. Remove the stop bolts and save.

3. Remove the two square drive screws attaching

the end cap to the roller tube, then separate

the roller tube and end cap. It will be

necessary to hold the roll bar and motor arm.

Allow the arm to extend out.

4. Use a scaffold or similar device to support the

roller tube.

CAUTION

Do not allow the roller tube

to drop toward the ground. The twisting

motion can cause serious damage to the

idler arm.

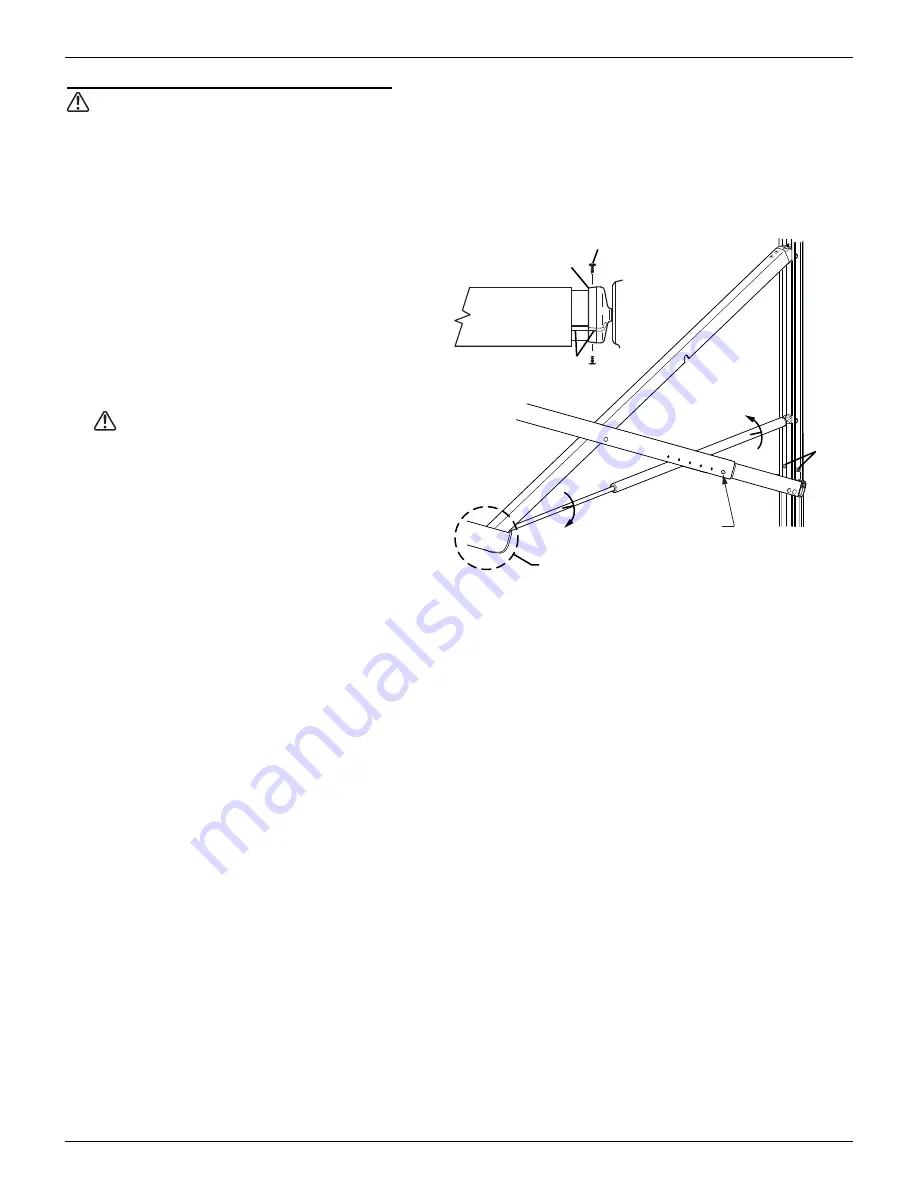

5. Support the arm in the area shown.

6. Unscrew the shock barrel from the clevis in the

mounting channel.

Tip: Wearing a pair of rubber gloves will aid in gripping the surfaces of the shock.

7. Unscrew the shaft from the clevis in the arm joint. Set old shock aside.

NOTE:

It may be necessary to use vice grips or pliers on the old shock to unscrew the shock from the

clevis. DO NOT use vice grips or pliers on the new shock. Damage to the surface of the shaft or

damage to the barrel can cause the new shock to not work.

8. Unpack the new shock and carefully allow it to extend to its maximum length.

9. Insert the new shock between the upright struts.

10. Coat the threads of the shaft of the new shock with a non-permanent thread lock (i.e. loctite) then screw

the rod into the clevis of the arm elbow. Hand-tighten only.

11. Lift and hold the arm up in the area indicated in Figure 9. The arm should be unfolded and extended as

far as possible.

12. Coat the threads of the barrel of the new shock with a non-permanent thread lock (i.e. loctite) then

screw the barrel into the clevis in the mounting channel. Hand-tighten only. It will be necessary to grip

and hold the shaft while turning the barrel.

13. Align the roll bar with the end cap on the arm assembly. Rotate the end cap until the slot in the cap

aligns with the empty slot in the roller assembly, and then press the roller assembly fully into the cap.

The end cap must seat squarely over the end of the roller assembly when complete.

14. Secure the end cap to the roller assembly using two #10 x 5/8 square-drive screws.

15. Partially retract the awning. It may be necessary to lightly pull down on the lower arm at the mounting

channel until the rollers are past the location of the stop bolts. Always pull down from the bottom of the

arm to avoid pinching.

16. Reinstall the stop bolts removed in step 2.

E0054

Loosen

Loosen

Stop

Bolts

Set Arm at

Minimum Pitch

Support and Lift in this area

Align Slots

End Cap

#10 x 5/8 Screw (x2)

Summary of Contents for ECLIPSE 2015

Page 4: ......