10

• These instructions are aimed at professionally qualified "

installers of electrical

equipment

" and must respect the local standards and regulations in force. All

materials used must be approved and must suit the environment in which the

installation is situated.

• All maintenance operations must be carried out by professionally qualified techni-

cians. Before carrying out any cleaning or maintenance operations make sure the

power is disconnected at the mains.

• This appliance must be used exclusively for the purpose for which it has been

made. "i.e.

for the automation of hinged gates

" with one or two gate leaves.

• The unit may be fitted both to the

right

and to the

left

of the passageway. This

product and all its relative components has been designed and manufactured by

Cardin Elettronica who have verified that the product conforms in every aspect

to the safety standards in force. Any non authorised modifications are to be

considered improper dangerous and the complete responsibility of the installer.

Caution!

mechanical stop buffers must be installed in both the open-

ing and closing positions (pos. 1, 2, 3, fig. 7).

It is the responsibility of the installer to make sure that the following public safety

conditions are satisfied:

1) Ensure that the gate operating installation is far enough away from the main

road to eliminate possible traffic disruptions.

2) The ram must be installed on the inside of the property and not on the public

side of the gate. The gates must not swing outwards onto a public area.

3) The ram is designed for use on gates through which vehicles are passing.

Pedestrians should use a separate entrance.

4) The gate must be in full view when it is operating therefore controls must be

situated in a position where the operator can see the gate at all times.

5) At least two warning signs (similar to the example on the right) should be

placed, where they can be easily seen by the public, in the area of the system

of automatic operation. One inside the property and one on the public side of

the installation. These signs must be indelible and not hidden by any objects

(such as tree branches, decorative fencing etc.).

6) Make sure that the end-user is aware that children and/or

pets must not be allowed to play within the area of a gate

installation. If possible include this in the warning signs.

7) Whenever a fully open gate leaf comes within

at least 500

mm

of a fixed structure the space must be protected by

an anticrush buffer.

8) A correct earth connection is fundamental in order to guar-

antee the electrical safety of the machine

9) If you have any questions about the safety of the gate operating system, do not

install the ram. Contact your dealer for assistance.

TECHNICAL DESCRIPTION

200/BLA24S

Self-locking electromechanical

24 Vdc

ram suitable for hinged

gates up to

3 m

in length and

150 kg

in weight (per gate leaf).

200/BLA24L

Self-locking electromechanical

24 Vdc

ram suitable for hinged

gates up to

4 m

in length and

300 kg

in weight per gate leaf (up to

5 m, 300

kg

addition of an electric locking device).

-

24 Vdc

motor with a steel never ending screw.

- External carter in extruded aluminium.

- Release mechanism components in shockproof plastic.

- Geared motor with steel gears enclosed in a die cast 2-piece aluminium

shell.

- Brackets and accessories in zinc-plated steel.

- Lubrication using permanently fluid grease.

ACCESSORIES

206/BLSTA

- Front and rear brackets.

206/BLASR

- Adjustable front and rear brackets.

980/XLSE11C

- Electric locking device

12 Vac

Attention!

Only for EU customers -

WEEE marking

.

This symbol indicates that once the products life-span has expired

it must be disposed of separately from other rubbish. The user

is therefore obliged to either take the product to a suitable dif-

ferential collection site for electronic and electrical goods or to

send it back to the manufacturer if the intention is to replace it

with a new equivalent version of the same product.

Suitable differential collection, environmental friendly treatment and disposal

contributes to avoiding negative effects on the ambient and consequently

health as well as favouring the recycling of materials. Illicitly disposing of this

product by the owner is punishable by law and will be dealt with according

to the laws and standards of the individual member nation.

During the opening/closing manoeuvre check for correct operation and activate

the emergency stop button in case of danger.

During blackouts the gate can be released and manually manoeuvred using the

supplied release key (see manual release mechanism).

Periodically check the moving parts for wear and tear and grease if required,

paying particular attention to the never ending screw pos. 13 fig. 2, using

lubricants which maintain their friction levels unaltered throughout time and are

suitable for temperatures of

-20 to +70°C

.

In case of failure or operational anomalies switch off the power at the mains

do not attempt to repair the appliance yourself. Periodically check the correct

operation of all safety devices (photoelectric cells etc.).

Eventual repair work must be carried out by specialised personnel using original

spare parts. The appliance is not suitable for continuous operation and must be

adjusted according to the model (see technical data on page 20).

The minimum controls which may be installed are OPEN-STOP-CLOSE, these

controls must be installed in a location not accessible to children.

Before starting the installation of the system check that the structure which is

to be automated is in good working order and respects the local standards and

regulations in force.

To this end make sure that the gate is sufficiently rigid (if necessary reinforce the

structure) and that the runner guides slide easily.

You are advised to grease all the moving parts using lubricants which maintain

unaltered friction characteristics over a period of time and are suitable for tem-

peratures of

-20 to +70°C

.

• Check the safety measures between the fixed and moving parts:

- a minimum space of

30 mm

must always be left along the entire distance

between the gate and the support column measured throughout the entire

opening angle of the gate;

- make sure that the space between the bottom of the gate and the pave-

ment never exceeds

30 mm

throughout the entire opening angle of the gate.

• The surface of the gate must not feature openings which allow a person’s

hand or foot to pass through.

• Check the exact positioning of the pivots, and their good working order (the

upper and lower hinges/pivots must be aligned on the same axis).

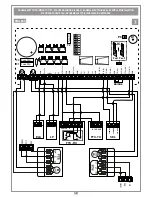

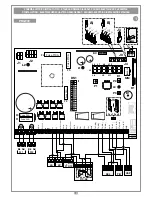

• Work out the run of the cables according to the command and control devices

fitted and make sure the system conforms to the local standard and regulations

in force (see installation example fig. 1 pag. 2).

• Check that the appliance is suitable for the size, weight and duty cycle of the

gate to which it is to be applied (see duty cycle on page 20).

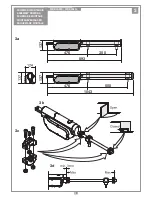

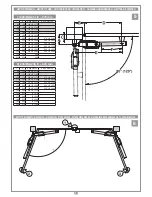

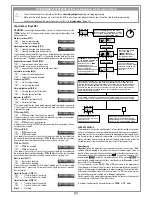

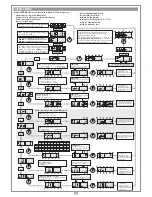

BLA24 INSTALLATION

Before reading the installation instructions, take note of the following basic concepts:

- the joint brackets (front and rear) must be mounted correctly at two different

heights;

- the brackets supplied can be welded directly to the structure or secured with

screws and screw anchors, provided the system is able to withstand the forces

imparted: by the actuator, by manual movement of the gate and (in certain condi-

tions) by the wind;

- the position of the brackets establishes the maximum opening angle and the

length of the actuator's linear stroke; consider that the longer the stroke of the

lead screw, the greater the torque and the smoother the movements of the gate

leaf; on the contrary, with a short stroke, movements may be more abrupt and

there will be less torque available. Tables "

1

" and "

2

" on page 6 show several

examples of bracket positions; the measurements are only guidelines and should

be used solely to prepare for installation.

APERTURA AUTOMATICA

NON AVVICINARSI

NON PERMETTERE A BAMBINI O AD

ANIMALI DOMESTICI DI SOSTARE NEL

RAGGIO D'AZIONE DEL CANCELLO

ATTENZIONE

IMPORTANT SAFETY INSTRUCTIONS

INSTALLATION INSTRUCTIONS

IMPORTANT REMARKS

IMPORTANT REMARKS

IMPORTANT REMARKS

READ THE FOLLOWING REMARKS CAREFULLY BEFORE PROCEEDING WITH THE INSTALLA-

TION. PAY PARTICULAR ATTENTION TO ALL THE PARAGRAPHS MARKED WITH THE SYMBOL

NOT READING THESE IMPORTANT INSTRUCTIONS COULD COMPROMISE THE CORRECT WORK-

ING ORDER OF THE SYSTEM AND CREATE DANGER SITUATIONS FOR THE USERS OF THE SYSTEM.

USER INSTRUCTIONS