S T E P 2

S T E P 2 – Y ‑ R a i l s

10

docs.carbide3d.com

11

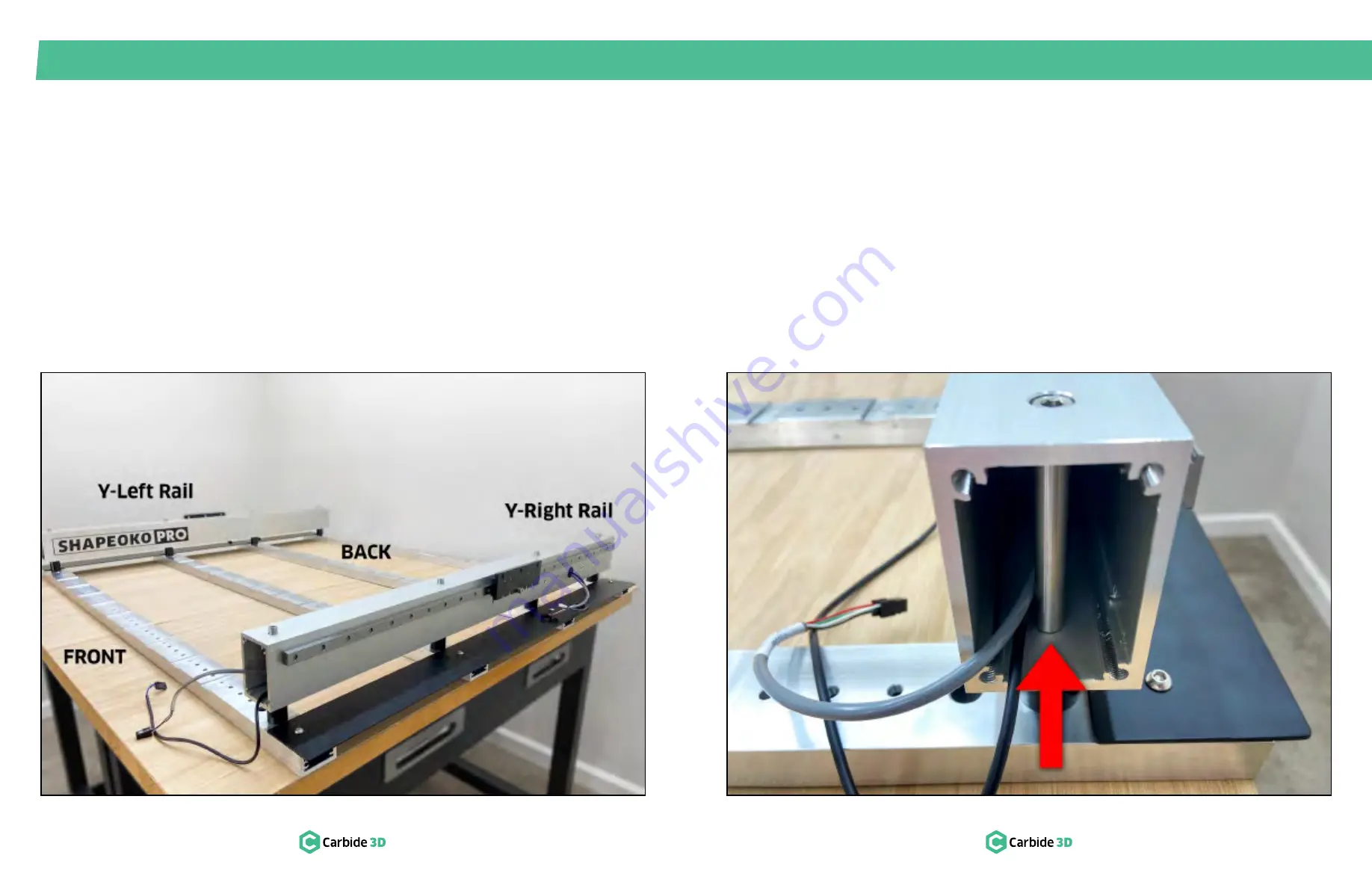

2.1 Install the Y‑Left Rail

1. Position the Y-Left extrusion rail on the four

standoffs on the left side of the baseframe.

See

Fig. 2-2

.

a. Shapeoko Pro decal to inside-front.

b. Linear rail and carrier plate to outside.

NOTE:

Don’t remove the SHCS shipping screws

keeping the carrier plates from moving just yet.

Figure 2-2

2.2 Install Y‑Right Rail

1. Position the Y-Right extrusion rail on the four

standoffs on the right side of the baseframe.

See

Fig. 2-2

.

a. Carbide 3D/flag decal to inside-front.

b. Linear rail and carrier plate to outside.

2. Pull the ends of the two cables out of the front

of the rail.

Figure 2-3

3. Use a 5mm hex key and four (4) M6×85mm

shoulder bolts to loosely attach the Y-Right rail

to the standoffs.

a. Insert bolts in order: front, back, center.

b. Ensure bolts fit snugly into the lower

through-holes with the shoulder flush

against the rail as shown in

Fig. 2-3

.

c. Snug the bolts, then back out ¼ turn.

2. Use a 5mm hex key and four (4) M6×85mm

shoulder bolts to loosely attach the Y-Left rail

to the standoffs.

See

Fig. 2-2

.

a. Insert bolts in order: front, back, center.

b. Ensure bolts fit snugly into the lower

through-holes with the shoulder flush

against the rail as shown in

Fig. 2-3

.

c. Snug the bolts, then back out ¼ turn.