9

step 4: installing anti-tip device

WARNING!

• All ranges can tip

• Injury to persons and

property could result

• Install anti-tip device

packed with range

• See installation instructions

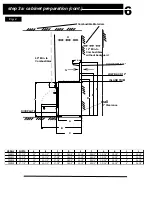

Fig. 5

WARNING!

RANGE TIPPING HAZARD!

1) All ranges can tip and injury can result.

To prevent accidental tipping of the range,

attach it to the floor, wall or cabinet by

nstalling the Anti-Tip Device supplied.

2) A risk of tip-over may exist if the

appliance is not installed in accordance

with these instructions.

3) If the range is pulled away from the wall

for cleaning, service or any other reason,

ensure that the Anti-Tip Device is properly

reengaged when the range is pushed back

against the wall.

4) In the event of abnormal usage (such

as a person standing, sitting, or leaning

on an open door), failure to take this

precaution can result in tipping of the

range. Personal injury might result

from spilled hot liquids or from the

range itself (Fig. 5).

READ THESE IMPORTANT

SAFETY WARNINGS!

WARNING!

ELECTRICAL SHOCK HAZARD!

1) Use extreme caution when drilling

holes into the wall or floor. There may be

concealed electrical wires located behind

the wall or under the floor.

2) Identify the electrical circuits that

could be affected by the installation

of the Anti-Tip Device, then turn off

power to these circuits.

3) Failure to follow these instructions

may result in electrical shock or other

personal injury.

CAUTION!

PROPERTY DAMAGE!

• Contact a qualified installer or contractor

to determine the proper method for drilling holes

through the wall or floor material (such as

ceramic tile, hardwood, marble, etc.).

• DO NOT slide range across unprotected floor.

• Failure to follow these instructions may result in

damage to wall or floor coverings.

NOTE:

The anti-tip device supplied with each range

MUST be installed per these instruictions!

failure to do so WILL void warranty.

TOOLS NEEDED FOR INSTALLATION OF

ANTI-TIP DEVICE!

1. Screwdriver, Phillips

2. Drill, electric or hand

3. Measuring tape or ruler

4. 1/8” drill bit (wood or metal wall or floor)

5. 3/16” carbide-tipped masonry drill bit

(concrete or concrete block wall or floor)

6. 3/16” anchors, drywall, or concrete, 2 each

(not required if mounting bracket is being

attached to solid wood or metal.

7. Hammer

8. Pencil or other marker

start here!

A.