3

where the temperature becomes 80

°

C or higher.

・

When install this product, use flexible coupling.

1.

Before Use

1-1

General Precautions

This section gives general precautions to ensure the correct use of this product.

For safety about individual items, take precautions given at the corresponding

sections.

At the beginning of work, check that this product functions normally.

If this product should become faulty, take full safety measures to prevent damage

to your device.

Do not use the product outside the range specified in this manual or alter it.

Do not disassemble the product or insert a tool through a gap. Doing so may

cause mechanical damage or damage the circuit by static electricity.

1-2

Installation Place

Mount the product in an ambient temperature range from 0 to 50

°

C, avoiding

direct sunlight and a heat source.

Use the product away from a noise source, such as high-voltage power supply,

large capacitance relay, large-current switch, or large-power inverter.

Route the head cable and extension cable away from any power line.

In an environment where oil mist or metal slug is anticipated, attach a cover to

prevent their entry.

1.

1.

1.

1.

Before Use

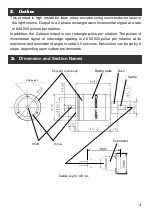

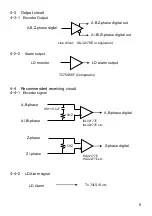

2.

2.

2.

2.