(4) Waste ink counter setting

When the logic board ass'y is replaced, reset the waste ink counter. In addition, according to the waste ink amount, replace the waste ink absorber (the bottom

case unit or the ink absorbers). The standard amount for waste ink absorber replacement is given in the table below.

*1: Check the waste ink amount by service test print or EEPROM information print.

[See 3.3. Adjustment / Settings, (6) Service mode, for details.]

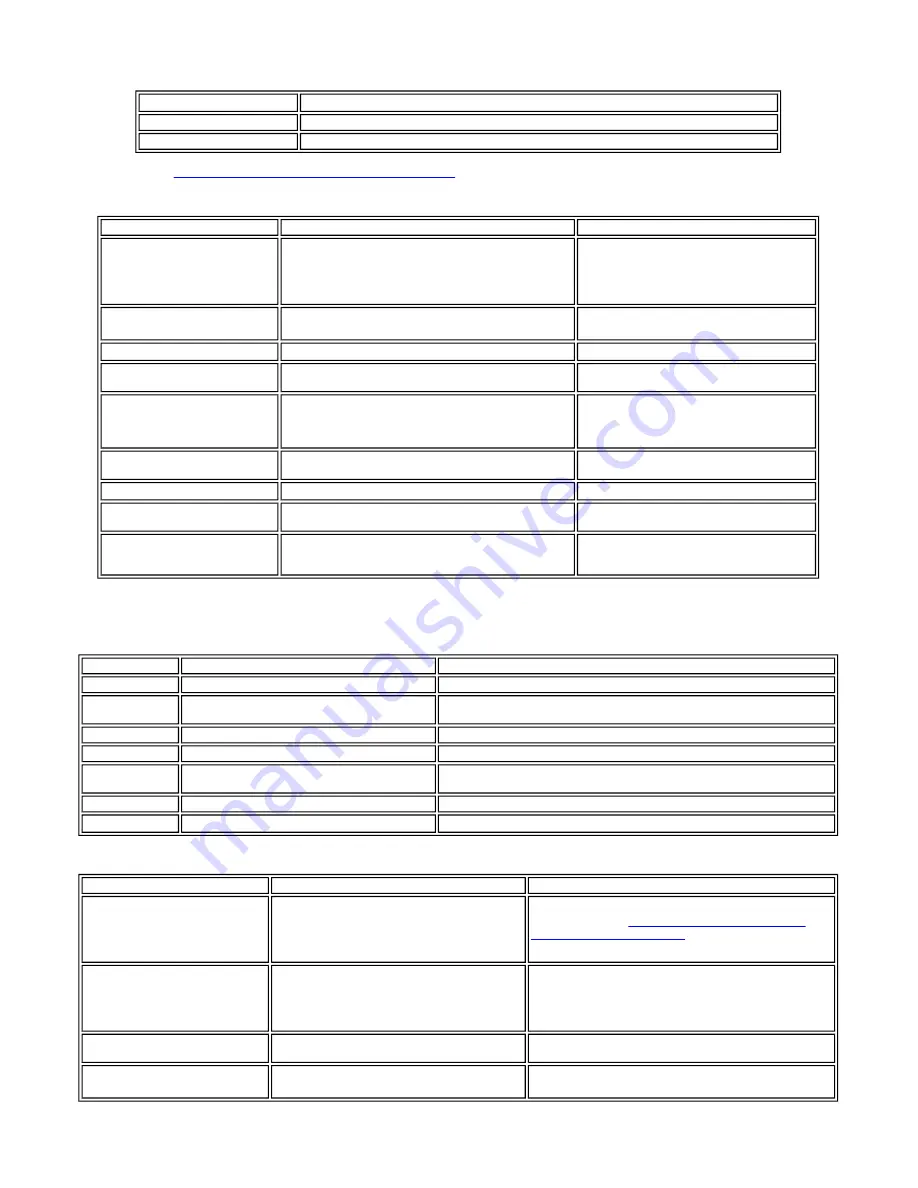

(5) User mode

<Standalone printer operation>

1) Turn on the printer.

2) Press and hold the Resume/Cancel button until the LED blinks the specified number of times listed in the table below, and release it. The operation starts.

(6) Service mode

Note: At the end of the service mode, press the Power button. To protect the media sensor from being dislocated during transportation, the paper lifting plate

of the sheet feeder unit will be raised.

Waste ink amount

*1

Bottom case unit or ink absorber replacement

Less than 7%

Not required.

7% or more

Required.

Function

Procedures

Remarks

Print head manual cleaning

- Cleaning both black and color:

See "Standalone printer operation" below.

- Cleaning black or color separately, or both black and color:

Perform from the printer driver's Maintenance tab.

Print head deep cleaning

- Cleaning black or color separately, or both black and color:

Perform from the printer driver's Maintenance tab.

Paper feed roller cleaning

See "Standalone printer operation" below.

Nozzle check pattern printing

See "Standalone printer operation" below.

Also available from the printer driver's

Maintenance tab.

Print head alignment

See "Standalone printer operation" below.

In Custom Settings of the printer driver's

Maintenance tab, manual print head alignment (by

selecting the optimum values) as with the

conventional models can be performed.

Bottom plate cleaning

Perform from the printer driver's Maintenance tab.

Cleaning of the platen ribs when the back side of

paper gets smeared.

CD-R print position adjustment

Perform from the application software.

Ink tank replacement

Open the access cover. When the carriage stops at the center,

an ink tank can be replaced.

Print head replacement

The print head is replaceable at the same position as for ink

tank replacement. (Open the access cover. When the carriage

stops at the center, the print head can be replaced.)

LED blinking

Operation

Remarks

1 time

Print head manual cleaning

2 times

Nozzle check pattern printing

Set a sheet of plain paper (A4 or letter) in the ASF or the cassette (according to the

Paper Feed switch setting).

3 times

Paper feed roller cleaning

4 times

Automatic print head alignment

Set a sheet of plain paper (A4 or letter) in the ASF.

5 times

Bottom plate cleaning

Fold a sheet of plain paper (A4 or letter) in half crosswise, then unfold and set it in the

ASF with the folded ridge facing down.

6 times

Unspecified

7 times

Set the widest head-to-paper distance

Function

Procedures

Remarks

Service test print

- Model name

- ROM version

- Waste ink amount

- CD-R sensor correction

See "Service mode operation procedures" below.

Set a sheet of A4- , letter-, or larger-sized paper.

For print sample, see

3-4. Verification Items, (1) Service test

print, <Service test print sample>.

EEPROM initialization

See "Service mode operation procedures" below.

The following items are NOT initialized:

- USB serial number

- Destination settings

- Waste ink counter

- CD-R correction value

Waste ink counter reset

See "Service mode operation procedures" below.

If the waste ink amount is 7% or more, replace the bottom case

unit, or the ink absorbers.

Destination settings

See "Service mode operation procedures" below.

Other than Japan: iP8500

Japan: iP8600

1 - 11

Summary of Contents for PIXUS iP8600

Page 5: ...Part 1 MAINTENANCE ...

Page 14: ... 3 Grease application 1 9 ...

Page 22: ...Part 2 TECHNICAL REFERENCE ...

Page 30: ...Part 3 APPENDIX ...

Page 31: ...1 BLOCK DIAGRAM To the top Part 3 1 BLOCK DIAGRAM 3 1 ...