CHAPTER 7 EXTERNALS/AUXILIARY MECHANISMS

COPYRIGHT © 1999 CANON INC. CANON NP6512/6612/7120/7130/7130F REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

7-15

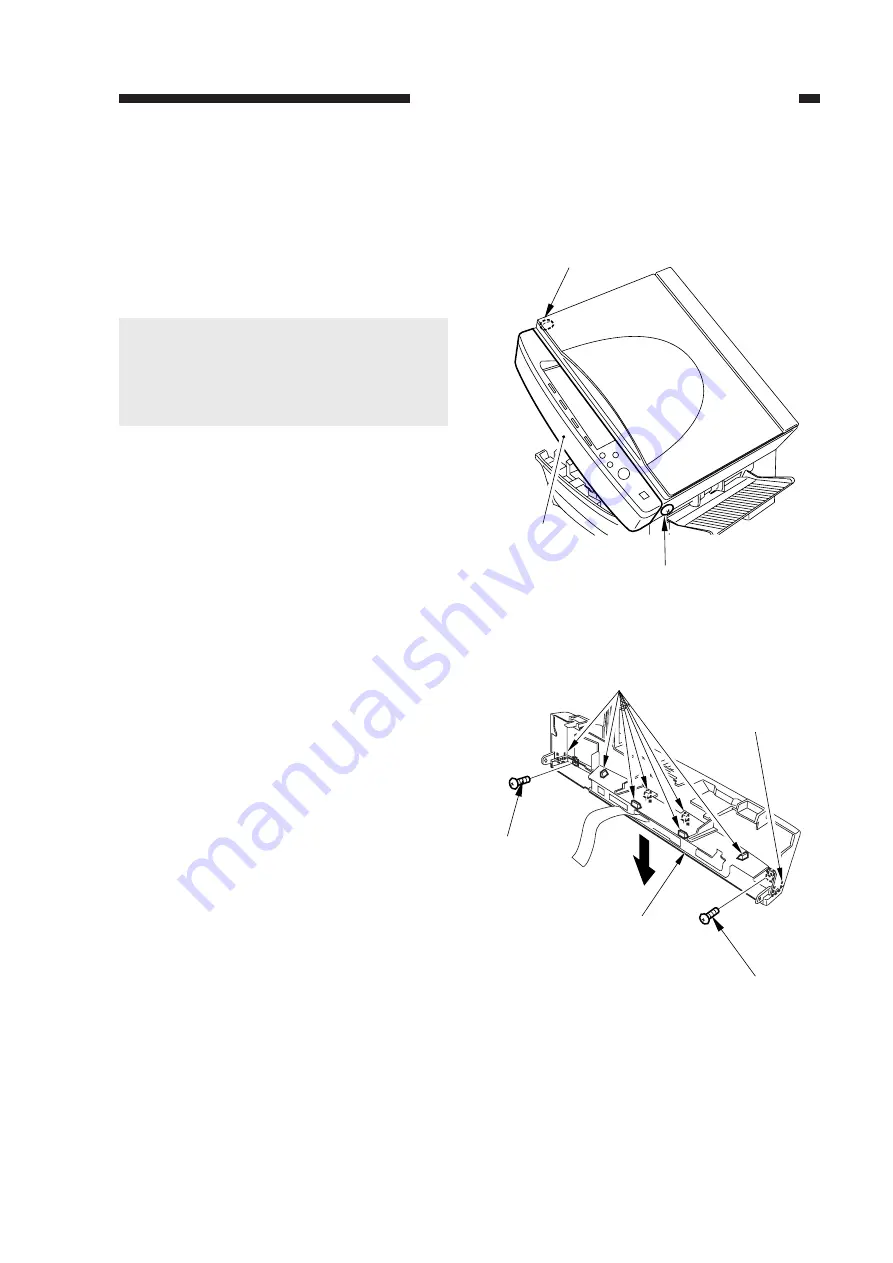

Figure 7-314

Figure 7-315

[1]

[1]

[2]

[4]

[4]

[3]

[3]

[5]

B.

Control Panel

1.

Removing the Control Panel

1) Open the machine’s top unit.

2) Remove the two screws [1], and detach

the front upper cover [2].

3) Remove the two screws [3], and free the

eight claws [4]; then, detach the control

panel [5].

Caution:

A flexible cable for the control panel is

connected to the front uper cover. Dis-

connect the cable from the DC control-

ler.

Summary of Contents for NP6412

Page 6: ......

Page 12: ......

Page 34: ......

Page 46: ......

Page 48: ......

Page 92: ......

Page 144: ......

Page 176: ......

Page 178: ......

Page 192: ......

Page 194: ......

Page 220: ......

Page 222: ......

Page 256: ......

Page 258: ......

Page 282: ......

Page 284: ......

Page 286: ......

Page 384: ......

Page 388: ......

Page 414: ......

Page 424: ......

Page 430: ......

Page 432: ......

Page 434: ......

Page 484: ......

Page 492: ......

Page 502: ......

Page 506: ......

Page 516: ......

Page 599: ...PRINTED IN JAPAN IMPRIME AU JAPON ...