Chapter 2

2-26

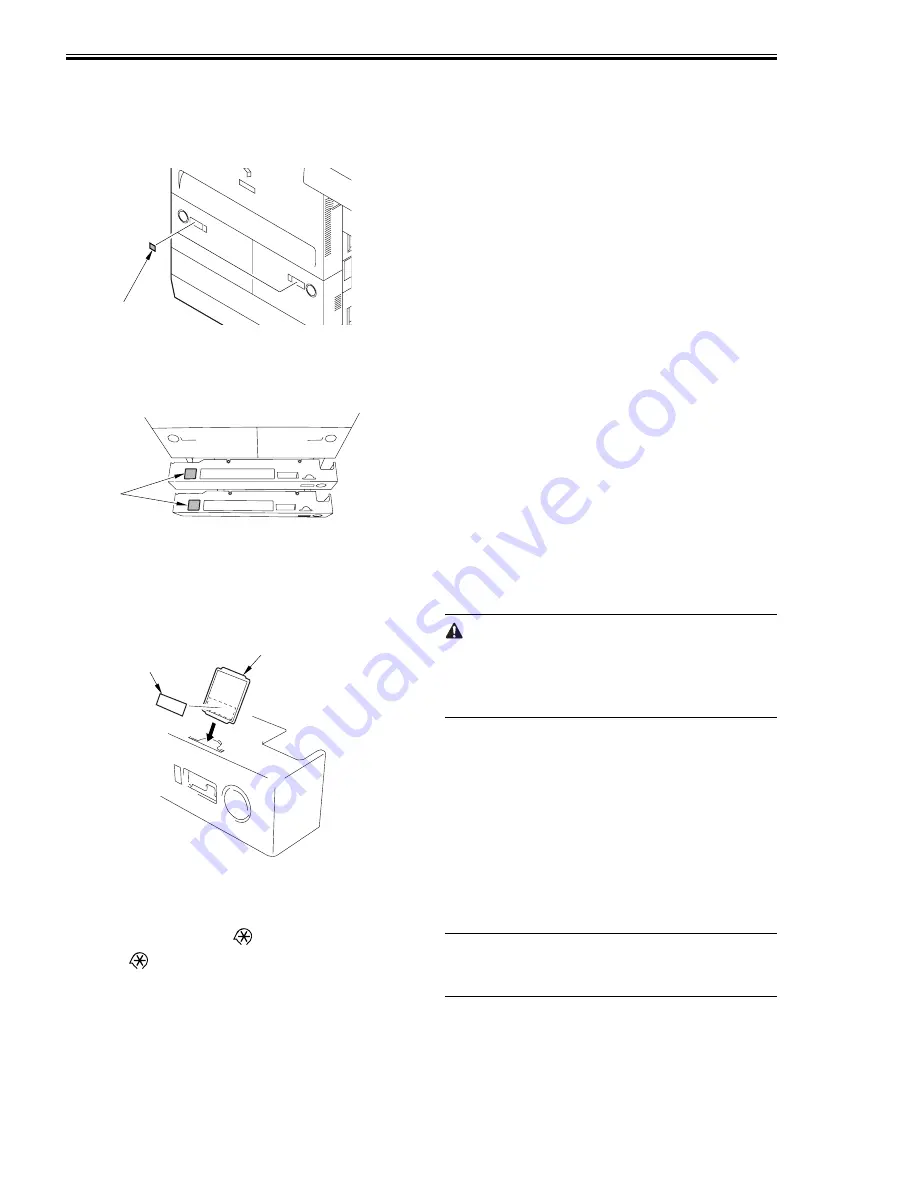

4) Put paper in the front deck (right/left).

5) Close the front deck (right/left). Remove the

appropriate size label (cassette/deck) from the

backing paper, and attach it to the paper size

plate of the deck.

F-2-104

6) Press the release button of the cassette 3/4, and

slide out the cassette.

7) Attach the 3-hole paper placement label [1].

F-2-105

8) Remove the appropriate paper size label

(cassette/deck) from the backing paper, and

attach it to the paper size plate [2] of the

cassette. Fit the paper size plate to the cassette

cover.

F-2-106

9) Close the deck/cassette.

10) To ensure stable reproduction of images,

generate 2 solid black prints (A3) as follows:

11) Start service mode. (

'2' and '8' at the same

time >

)

12) Make the following selections: COPIER >

TEST > PG > PG-PICK.

13) Select the source of paper containing A3

paper, and press the OK key.

('3' for cassette 3; '4' for cassette 4)

14) Make the following selections: COPIER >

TEST > PG > TYPE.

15) Type in '7', and press the OK key.

('7' for solid black; PG-TYPE7)

16) Press the Start key to generate a single solid

black (A3) print. Check the output, and wait for

about 5 sec. Then, press the Start key to

generate another print.

17) When done, press the Reset key twice to end

service mode.

18) Place the test sheet on the copyboard, and

check the copy image.

Check to be sure that the pickup operation for

all sources of paper is normal (by making 3 test

copies each from decks and cassettes).

- check to be sure that there is no abnormal

noise.

- check to see that images at all default

magnifications are normal.

- check to see that as many copies as

specified are made normally.

- if there is a difference in density between

left and right, correct it by adjusting the

height of the primary charging wire at the

front or the rear.

- Check to see that copying operation is

normal.

horizontal registration standard (margin at

image left): 2.5 +/-1.5 mm

lead edge registration standard (margin at

image lead edge): 4.0 +1.5/-1.0 mm

If not as indicated, make adjustments by

referring to the instructions under "Adjusting

the Horizontal Registration" and "Adjusting the

Lead Edge Registration."

At times, the first 10 copies or so may show

soiled images because of toner dropping from the

drum separation claw. The symptom should dis-

appear as additional copies are made.

19) Make double-sided copies to check the

machine operation.

20) Make standard settings in user mode and

service mode to suit the needs of the user.

21) Press the Reset key twice to end service

mode.

22) Clean up the area around the machine.

23) Move the machine to its final place, and fix it

in place using the adjusters.

24) If you are installing accessories, do so

according to their respective Installation

Procedures.

MEMO:

For the Card Reader-D1, see "Card Reader-D1

Installation Procedure."

25) Fill out the service sheet.

[1]

[1]

[1]

[2]

Summary of Contents for IMAGERUNNER 7095 PRINTER

Page 20: ...Chapter 1 Introduction...

Page 46: ...Chapter 2 Installation...

Page 88: ...Chapter 3 Basic Operation...

Page 94: ...Chapter 4 Main Controller...

Page 116: ...Chapter 5 Original Exposure System...

Page 165: ...Laser Exposure Chapter 6...

Page 175: ...Chapter 7 Image Formation...

Page 231: ...Chapter 8 Pickup Feeding System...

Page 287: ...Chapter 9 Fixing System...

Page 312: ...Chapter 10 External and Controls...

Page 346: ...Chapter 11 MEAP...

Page 350: ...Chapter 12 RDS...

Page 360: ...Chapter 13 Maintenance Inspection...

Page 375: ...Chapter 14 Standards Adjustments...

Page 407: ...Chapter 15 Correcting Faulty Images...

Page 433: ...Chapter 16 Self Diagnosis...

Page 460: ...Chapter 17 Service Mode...

Page 559: ...Chapter 18 Upgrading...

Page 583: ...Chapter 19 Service Tools...

Page 588: ...APPENDIX...

Page 615: ......