75

imagePRESS C850/C750/C650/C65

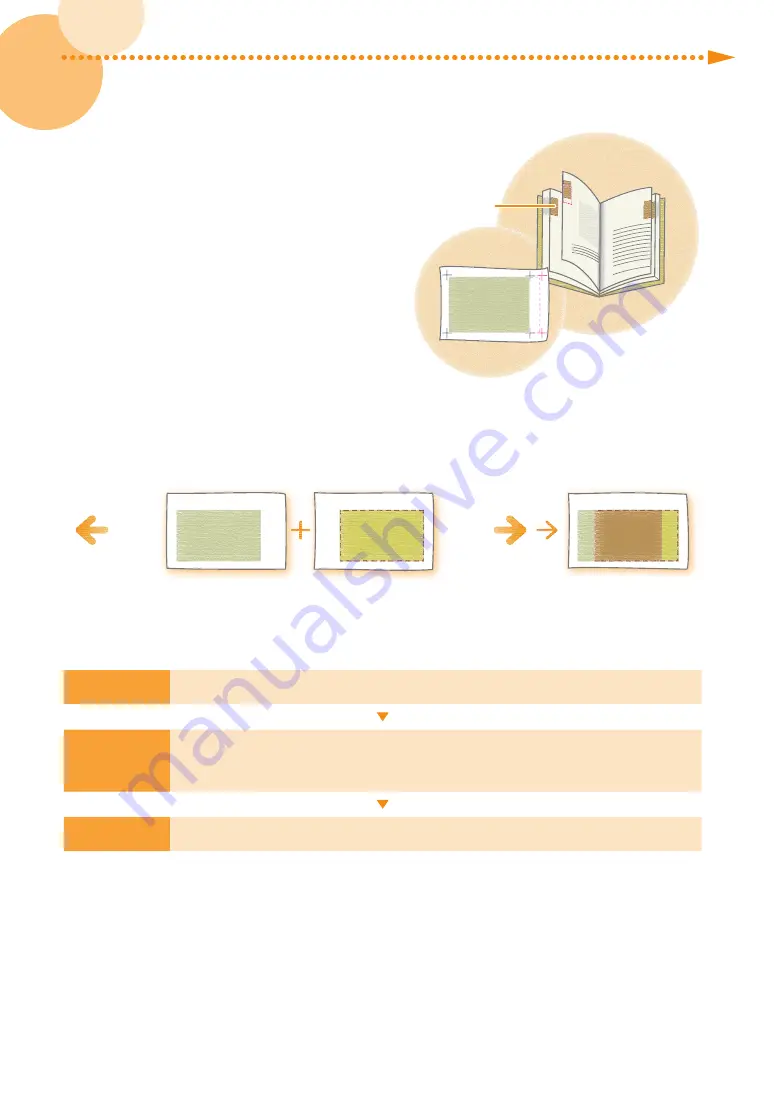

How to Fix Misalignment of Images

If the following troubles often occur, the machine may have

alignment problems� Follow the procedures described in this

section to solve such problems�

• The register marks on one side of a printed sheet do not

match those on the other side�

• The thumb indexes on the printed pages are not aligned�

• The image is not printed within the register marks�

NOTE

• You may not be able to correct misalignment that is less

than 1�0 mm (1/25")�

• The machine decides the printing start position based on

the leading edge of the paper� After the front side of the

paper is printed, the paper is reversed and the back side of the paper is printed from the trailing edge� Because of

this, the position where printing starts may be slightly different on opposite sides of the paper�

Front

Leading

Edge

Feeding

Direction

Back

Left Edge

Left Edge

Leading

Edge

Feeding

Direction

Images are misaligned on

both sides of the paper.

Step 1

Eliminating the Basic Causes of Misalignment (p� 76)

Step 2

Changing Settings on the Machine According to Paper Characteristics (p� 78)

• If Using the scanner (p� 78)

• If Not using the scanner (p� 82)

Step 3

Changing Print Settings on the Printer Driver (p� 86)

Thumb Index

Summary of Contents for imagePRESS C850

Page 2: ......