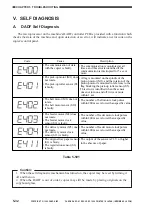

CHAPTER 5 TROUBLESHOOTING

5-32

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

V. SELF DIAGNOSIS

A.

DADF Self Diagnosis

The microprocessor on the machine's DADF controller PCB is provided with a function which

checks the state of the machine and, upon detection of an error, will indicate an error code on the

copier's control panel.

Table 5-501

Caution:

1. When the self diagnostic mechanism has turned on, the copier may be reset by turning it

off and then on.

2. When the DADF is out of order, copies may still be made by placing originals on the

copyboard glass.

Code

Cause

• The communication of data

with the copier is faulty.

• The communication is monitored at all

times, and this error is identified if the

communication is interrupted for 5 sec or

more.

• The pick-up motor (M1) does

not rotate.

• The pick-up roller sensor (S5)

is faulty.

• A flag is mounted on the spindle of the

pick-up motor (M1), and the rotation of the

pick-up motor is mounted in reference to the

flag blocking the pick-up roller sensor (S5).

This error is identified when the sensor

does not turn on and off twice or more

within 1 sec

• The belt motor (M3) doe not

rotate.

• The belt motor sensor (S10)

is faulty.

• The number of belt motor clock pulses

within 200 msec is lower than specific value.

• The feeder motor (M2) does

not rotate.

• The feeder motor clock

sensor (S9) is faulty.

• The number of feeder motor clock pulses

within 200 msec is lower than a specific

value.

• The delivery motor (M5) does

not rotate.

• The delivery motor clock

sensor (S13) is faulty.

• The number of feeder motor clock pulses

within 200 msec is lower than a specific

value.

• The original tray paper sensor

(S1) is fauity.

• The registration sensor (S3)

is faulty.

• The output of the sensor is 2.3 V or higher

in the absence of paper.

Description