Chapter 1

1-8

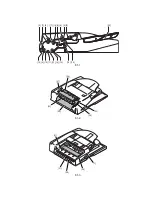

3. No. 1 Registration Roller, No. 2 Registration Roller, No. 1 Registration Roll, No. 2 Registration Roll, and

Reversing Roller.

1) Clean the following in the order indicated: platen roller, No. 1 registration roll [1], No. 1 registration roller [2],

No. 2 registration roll [3], No. 2 registration roller [4], reversing roller [5].

1. make the following selections in service mode to highlight [ROLL-CLN], and press the OK key to rotate the

rollers: FEEDER>FUNCTION>ROLL-CLN.

2. force lint-free paper moistened with alcohol against the rollers to clean them.

3. press the OK key to stop the rollers.

Memo:

The No. 1 registration roller and the No. 2 registration roller will not rotate even when the foregoing service mode is

executed (i.e., FEEDER>FUNCTION>ROLL-CLN).

F-1-8

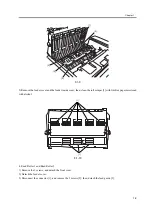

2) Clean the feeder inside cover [1], feed guide [2], reversing guide [3], delivery guide [4], and registration guide [5]

(including sheets) with lint-free paper moistened with alcohol.

[1]

[2]

[3]

[4]

[5]

Summary of Contents for DADF-M1

Page 1: ...Feb 21 2005 Portable Manual Feeder DADF M1 ...

Page 2: ......

Page 6: ......

Page 9: ...Chapter 1 Maintenance and Inspection ...

Page 10: ......

Page 12: ......

Page 26: ...Chapter 1 1 14 F 1 20 F 1 21 4 Clean the top face plastic film 1 of the prism 1 2 1 ...

Page 31: ...Chapter 2 Standards and Adjustments ...

Page 32: ......

Page 34: ......

Page 44: ......

Page 45: ...Chapter 3 Error Code ...

Page 46: ......

Page 47: ...Contents Contents 3 1 User Error Code 3 1 3 1 1 Alarm Code 3 1 ...

Page 48: ......

Page 50: ......

Page 51: ...Chapter 4 Outline of Components ...

Page 52: ......

Page 54: ......

Page 59: ...Chapter 5 System Construction ...

Page 60: ......

Page 62: ......

Page 69: ...Feb 21 2005 ...

Page 70: ......