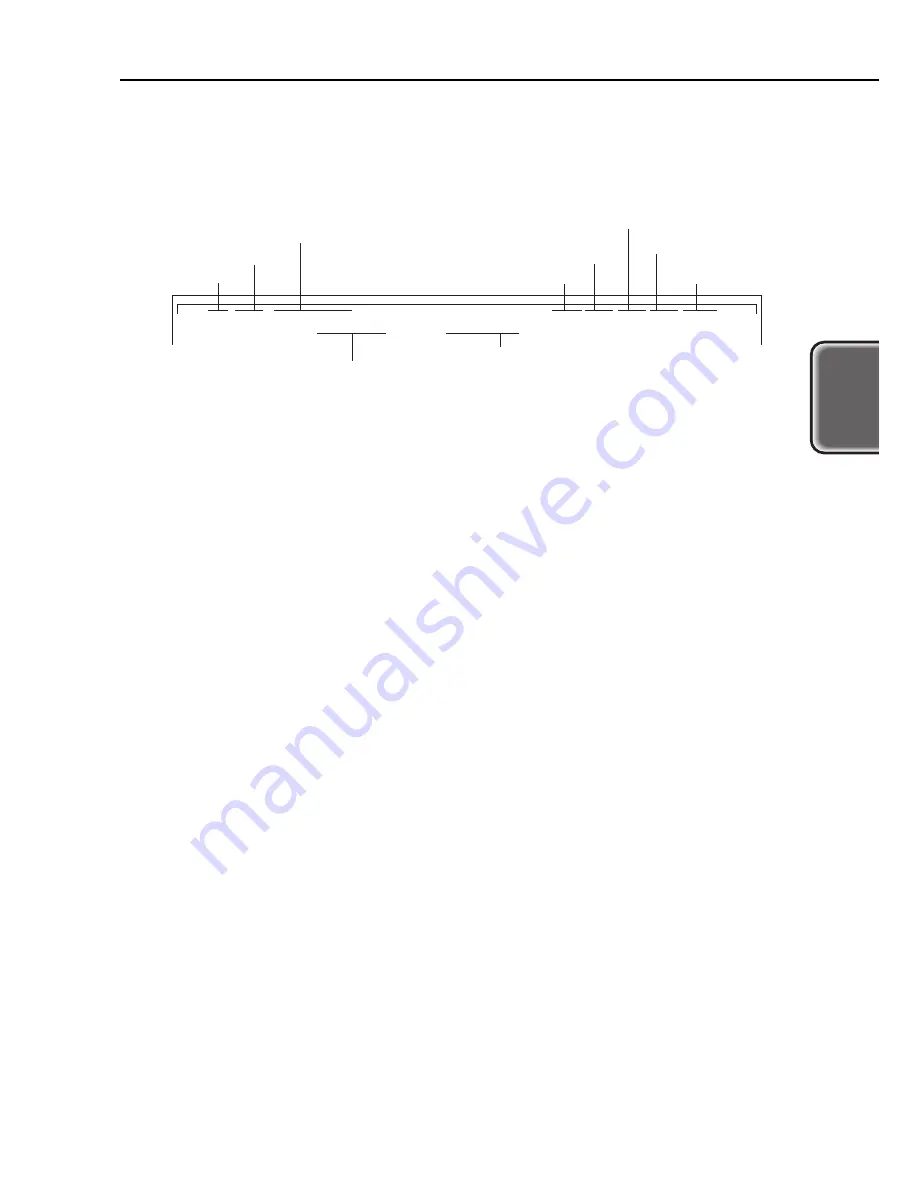

7.2 Service/Factory Test Printout

The header of the service/factory test printout shows the control ROM version, model setting, total printed

sheet count, total waste-ink absorption amount, and other information.

* USB serial No.

If multiple BJS-6200 printers are connected via USB, each printer will have a unique USB serial No. (in

accordance with USB standards) so that the computer can distinguish between them.

The unique USB serial No. is written in the EEPROM when the control board is manufactured. The USB

serial No. written in the EEPROM is not cleared even when the EEPROM is reset. Also, the USB serial

No. cannot be modified.

2-29

BJC-6200

Part 2: Troubleshooting

T

roub

leshooting

Installed cartridges

Model designation

Total printed sheet count with black/color

BJ cartridge

ROM version

Total printed sheet count with photo/color BJ cartridge

Total waste-ink amount (Waste-ink absorber's absorption capacity: %)

Serial No.* for USB

ROM Ver Vx.xx BJC-6200

Use Head <BC-30,BC-31> HeadTemp0=031.0 HeadTemp1=032.5 EnvironmentTemp=031.0 Bk=00000 C1=00257 Ph=00000 Sc=00000 ScC1=00000

Factory Area=01 00 00 00 00 01 1B 89 LostInkCount =03.9% Destination =01 USBSerialNo=(109BNF)

Total passed sheet count

with scanner cartridge

Unused

Unused

Figure 2-16 Service/Factory Test Printout (Sample)

Summary of Contents for BJC-6200

Page 2: ...042000 AB 0 20 0 ...

Page 3: ......

Page 10: ......

Page 12: ......

Page 22: ......

Page 34: ......

Page 54: ...Part 2 Troubleshooting BJC 6200 2 32 This page intentionally left blank ...

Page 56: ......

Page 72: ...Part 3 Appendix BJC 6200 3 16 This page intentionally left blank ...

Page 79: ......

Page 80: ...PRINTED IN JAPAN IMPRIME AU JAPON CANON INC The printing paper contains 100 waste paper ...