3

CUSTOMER CARE

Page

Guarantee ............................................................................................................................................................2

Statutory Requirements .......................................................................................................................................2

Contents ...............................................................................................................................................................3

INTRODUCTION ..................................................................................................................................................4

INSTALLER’S INSTRUCTION .............................................................................................................................5

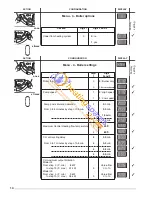

1 DESCRIPTION.................................................................................................................................................5

2 DIMENSIONS .................................................................................................................................................6

3 HYDRAULIC DATA .........................................................................................................................................6

4 INSTALLATION REQUIREMENTS .................................................................................................................7

Location ...................................................................................................................................................7

Flue ..........................................................................................................................................................7

Ventilation ................................................................................................................................................7

Gas Supply .............................................................................................................................................7

Electrical Supply ....................................................................................................................................7

Showers ...................................................................................................................................................7

Flushing and Water Treatment ...............................................................................................................7

System Controls ......................................................................................................................................7

Contents

STATUTORY REQUIREMENTS

The installation of this appliance must be carried out by a CORGI Registered person or other competent person and in

accordance with the requirements of the Gas Safety (Installation and Use) Regulations and the rules in force.

In GB it is necessary to comply with the Water Supply (Water Fittings) Regulation 1999, for Scotland, The Water Bylaws 2000,

Scotland. The Centora Green is an approved product under the Water Regulations.

To comply with the Water Regulations, your attention is drawn to The Water Regulations guide published by the the Water

Regulations Advisory Scheme (WRAS) gives full details of the requirements. In IE the requirements given under the current

edition of I.S.813 must be followed. installation must also comply with the current bylaws of Local Water Undertakings.

Installation should also be carried out in accordance with Building Regulations, Local Authority Building Standards (Scotland)

Regulations and current editions of the following British Standards Codes of practice: BS 7593, BS 5440 parts 1 and 2, BS

5449, BS 7593, BS 6798, BS 5546, BS 7074, BS 7671 and document IGE/UP/7.

In the Republic the Republic of Ireland the installation should be carried out in accordance with the following codes of practice:

I.S.813 Domestic Gas Installation, the following BS Standards give valuable information: BS 5546, BS 5449, BS 7074 and BS

7593.

The electrical connections must be made in accordance for GB with current I.EE. Wiring Regulations, in Scotland with the

electrical provisions of the Building Regulations applicable in Scotland, the Safety Document 635 The Electricity at Work

Regulation and in the Republic of Ireland in accordance with I.S.813 and the current ETCI rules.

The Centora Green does not contain any asbestos or asbestos products, or mercury derivatives. Additional CFC’s have not

been used in this product.

The appliance does not contain any potential hazard in relation to the COSHH regulations.

If there is a possibility of the incoming mains water pressure exceeding 10 bar then a suitable pressure limiting valve must be

fitted where pressures exceed 6 bars a pressure limiting valve is preferred.

Precautions: During servicing, keep the dust generation to a minimum and avoid inhaling any dust and contact with the skin

and eyes. Normal handling and use will not present any discomfort, although some people with a history of skin complaints

may be susceptible to irritation. When disposing of the ceramic lining, ensure that it is securely wrapped and wash hands after

contact.