10

11

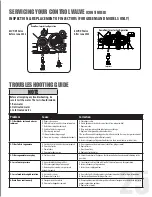

Turbidity Filter

(NEX) NexSand

Media Bed

nextSand

(Green)

Support Bed

(when supplied)

Fine, and/or Coarse

Gravel

Greensand

(IF/GS/ISF)

Media Bed

Greensand

(Grey)

Pot

Feeder

Support Bed

(when supplied)

Fine, and/or Coarse

Gravel

D-Tube

Unscrew Spill Cap

Internal O-ring

Upper cone on

TO models only

Tank Seal O-ring

PREPARATIONS

(CONTINUED)

4.

Apply the supplied lubricant (part #92360) to the internal O-ring at the bottom of the control valve.

Apply lubricant to the larger O-ring on the bottom of the valve that seals with the tank threads.

5.

Remove the tape from the top of the riser tube. Carefully position the valve over the riser tube, inserting riser into the internal O-ring.

Turn the valve clockwise into the threads of the tank until secure.

NOTICE

Make sure the quick connect power cord is not yet

connected to prevent the cord getting caught between

the threads of the tank and the valve.

NOTICE

Do NOT use petroleum-based

lubricants as they will cause

swelling of the O-ring seals.

Summary of Contents for 85DF

Page 27: ...Page intentionally blank...