XB, HV, HVA, HVAR, ADD, ADDR, DDS, DDP, SXB, SADD

M0112_NOV 2020

Page 4 of 8

www.CANARM.COM

Canarm Ltd. - Corporate Head Office

2157 Parkedale Avenue, PO Box 367 Brockville, Ontario Canada K6V 5V6

Tel: (613) 342-5424 Fax: (613) 342-8437

www

.canarm.com

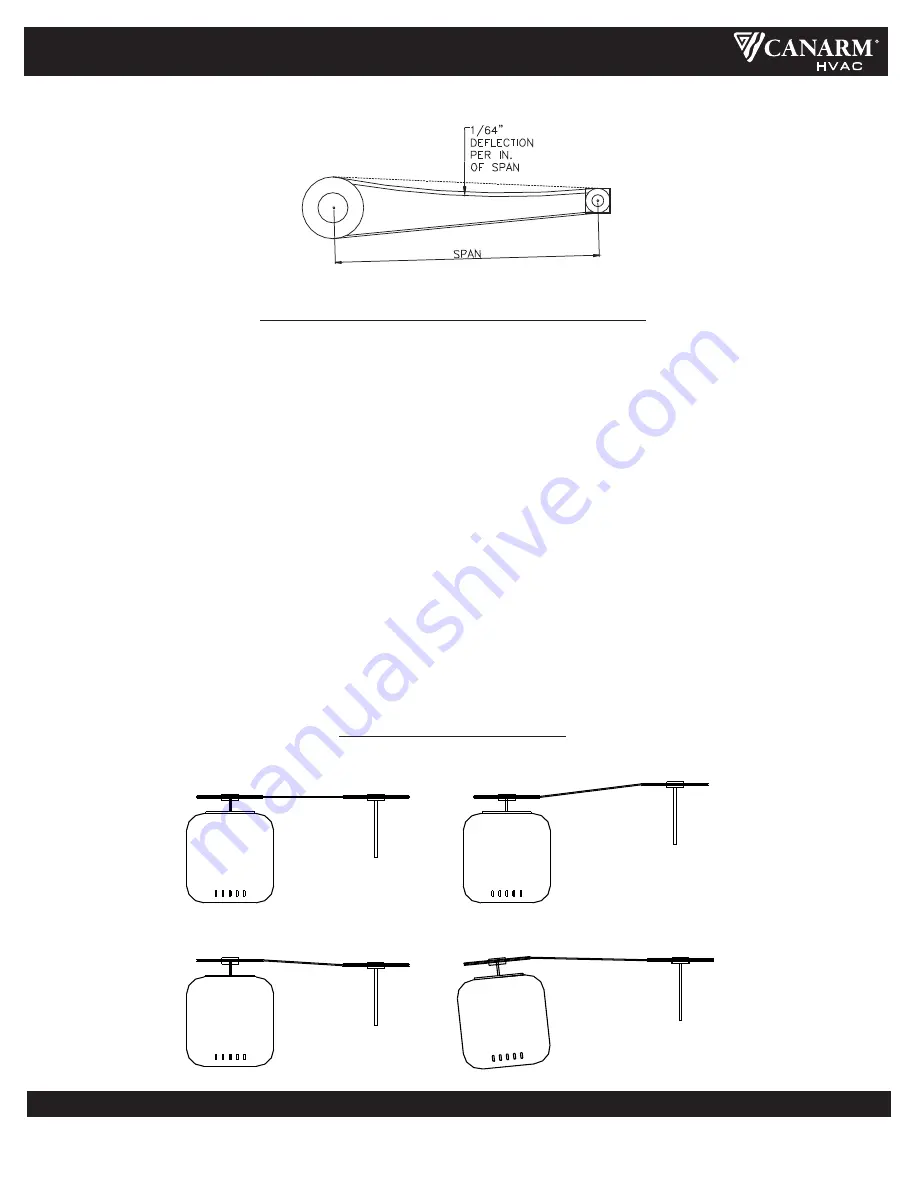

Belt Tension

BELT AND PULLEY REPLACEMENT

In the course of regular maintenance the belts and pulleys may have to be changed and or adjusted the

recommended procedure is as follows.

• Do not change the pulley pitch diameter in order to tension the belts. This will result in a change in the fan speed.

• Loosen the nuts on the motor plate or motor in order to reduce the belt tension such that the belts will easily slip

over the pulleys. Never force the belts over the rim of the pulley.

• Loosen the setscrews on the pulleys and remove from either the motor or fan shaft using a two or three jaw

puller.

• Remove any shaft imperfection such as setscrew mark using a file or emery cloth.

• Install the replacement pulleys tightening all setscrews to the recommended torque rating (see chart) and

ensuring that they are properly aligned.

• Pulley alignment is achieved by moving the pulleys on their respective shafts or moving the entire motor until

the pulleys are correctly aligned (see figure). Using a square with one edge parallel to the motor shaft adjust the

pulleys until the other edge is parallel to the belts.

• Slip the belts over the pulleys then adjust the motor/ motor plate until the proper tension is reached (1/64”

deflection, half way between pulley centers, per inch of belt span when pressed firmly).

• Tighten the motor plate/ motor adjusting nuts in place.

PULLEY ALIGNMENT

INCORRECT

CORRECT

INCORRECT

INCORRECT