Camus ProtoNode Start-up Guide

Page 26 of 87

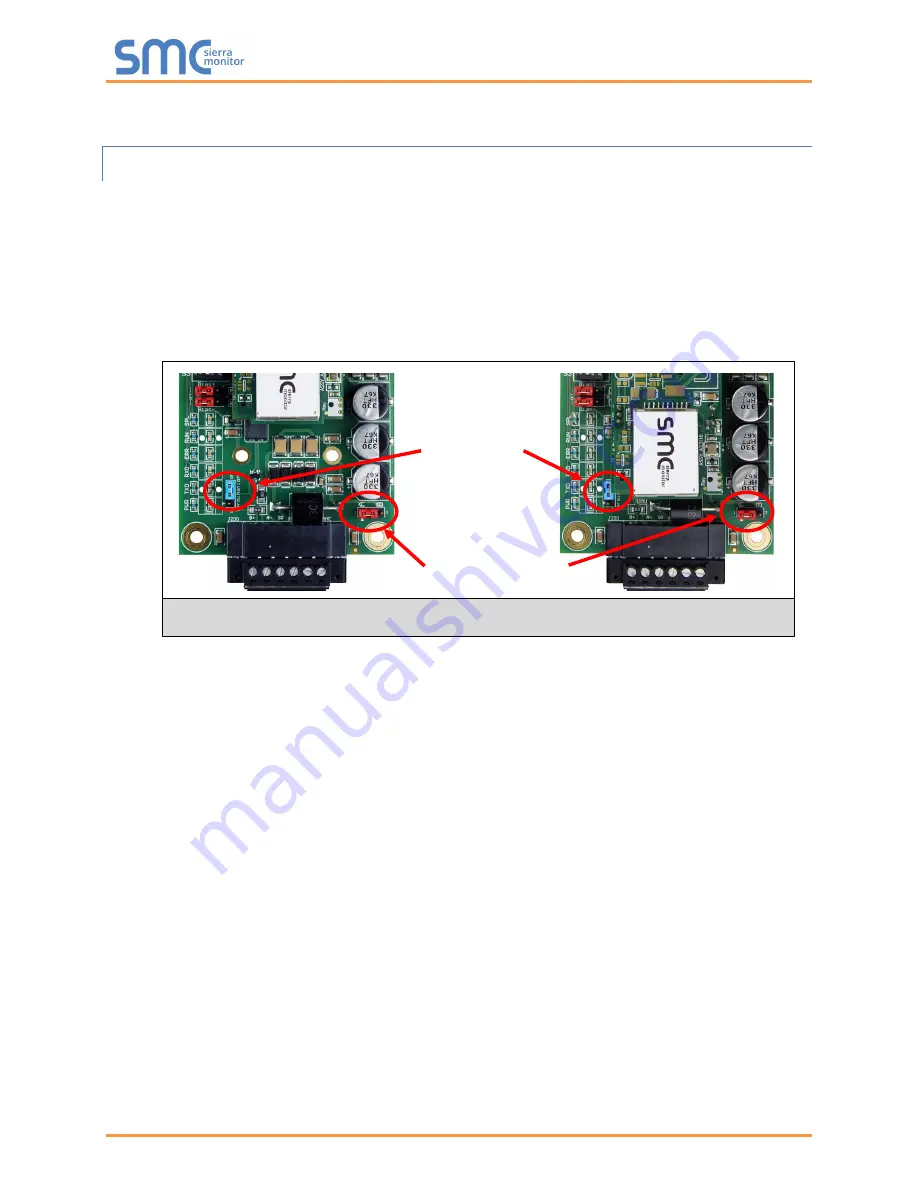

4.6.2 End of Line Termination Switch for the RS-485 Device Network

•

On long RS-485 cabling runs, the RS-485 trunk must be properly terminated at each end.

•

The ProtoNode has an end of line (EOL) blue jumper. The default setting for this blue EOL switch

is OFF with the jumper straddling the pins closest to the inside of the board of the ProtoNode.

o

On short cabling runs the EOL switch does not to need to be turned ON

•

If the ProtoNode is placed at one of the ends of the trunk, set the blue EOL jumper to the ON

position straddling the pins closest to the outside of the board of the ProtoNode.

•

Always leave the single red jumper in the A position (default factory setting).

RS-485 EOL

Switch

(off)

Leave in Position A

Figure 12: RS-485 End-Of-Line Termination Switch on the ProtoNode N34 (Left) and

ProtoNode N35 (Right)