13

2.1.3

APPROVED VENTING MATERIALS

Exhaust Vent for Use for Dynaforce® Category ll or lV

Installations

1 Manufactured prefabricated UL/ ULC listed vent of AL29-

4C or equivalent, Single or Double Wall.

2 316L stainless steel is limited to use in applications where

there is no possibility of contaminants in the air such as

refrigerants, chlorine etc.

3 “BH” type.

4 PVC and CPVC Schedule 40 or 80 approved to ULC S636

5 PVC-DWV approved to comply with ANSI/ASTM D2665

(US Jurisdictions ONLY when permitted)

6 PVC Schedule 40 approved to comply with ANSI/ASTM

D1785 (US Jurisdictions ONLY when permitted)

7 CPVC Schedule 40 approved to comply with ANSI/ASTM

F441. (US Jurisdictions ONLY when permitted)

8 Polypropylene approved to comply with ULC S636 up to 12”

diameter.

NOTE

1) Use of cellular core PVC (ASTM F891), cellular core

CPVC or Radel® (polyphenosulfone) in venting systems

is prohibited.

2) Covering non-metallic vent pipe and fittings with thermal

insulation is prohibited.

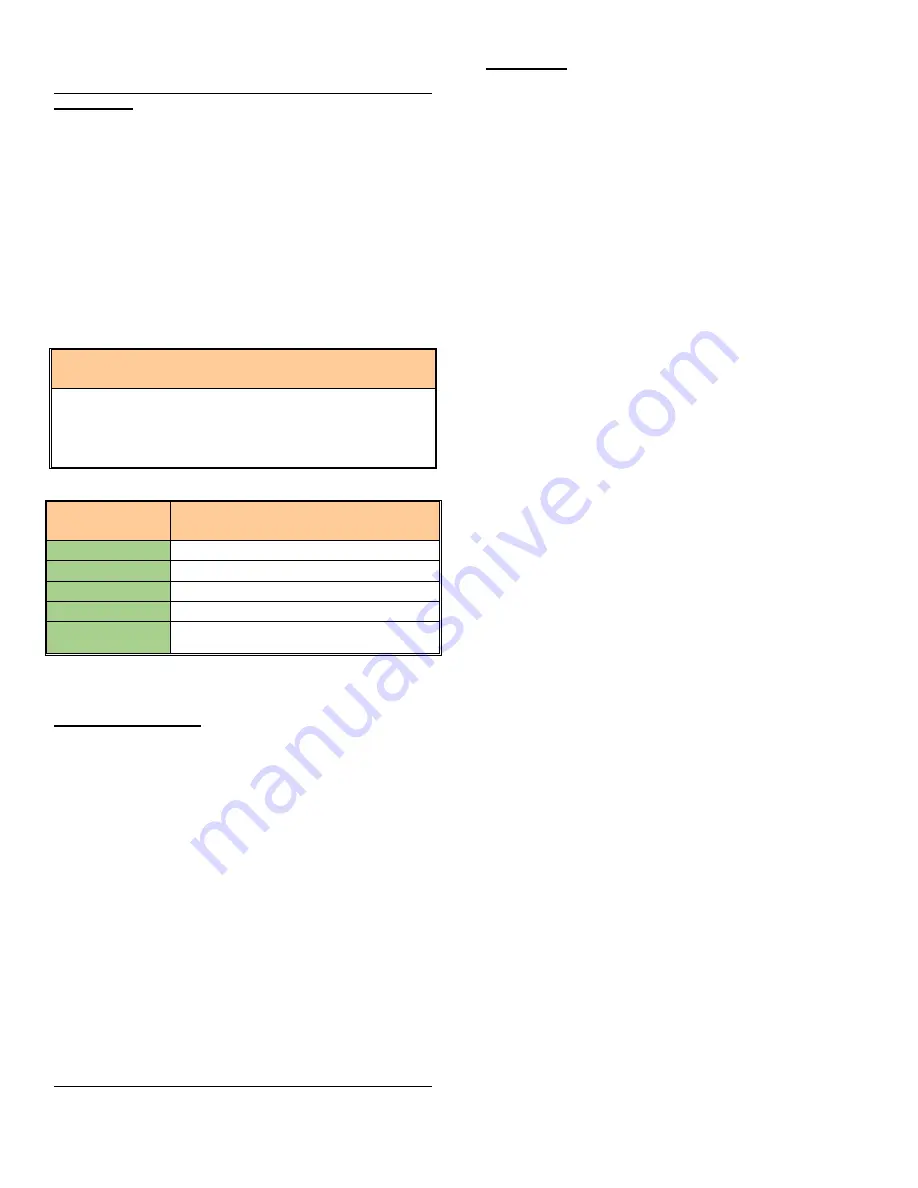

Table 4: Maximum Flue Temperature for Various Vent Materials

Vent Material

Maximum Flue Temperature [

o

F]

PVC

149

CPVC

194

Polypropylene

230

AL29-4C

300+, limited only by rating of seals

316L Stainless

Steel

300+, limited only by rating of seals

Stack temperature is 10-15

o

F above boiler inlet temperature

when operating at steady-state.

Vent material selection

When selecting vent material take into consideration that

appliances installed near a corrosive or potentially corrosive air

supply must be isolated from it or they will suffer damage to the

appliance and the venting system.

The corrosion resistance of AL29-4C is typically higher than that

of 316L. Always choose the venting system which best satisfies

the requirements of the application

.

This recommendation does not supersede local codes or

the provision of the B149 in Canada or the National Fuel

Gas Code in the United States

Single wall air intake pipes are to be insulated 5 feet from wall

toward the interior of the building to minimize external sweating.

Intake Air (Supply Air, or Fresh Air) Piping for Direct Vent

Applications

Air intake material must be of a type listed by a nationally

recognized testing agency.

1

PVC

Non Foam Core Pipe.

2

CPVC

Non Foam Core Pipe.

3

Polypropylene

4

ABS

(Acrylonitrile-Butadiene-Styrene).

Single wall vent pipes to be insulated 5 feet from wall toward the

interior of the building to minimize external sweating.

2.1.4

VENT TERMINATION CLEARANCES

•

Do not terminate the vent in a window well, stairwell, alcove,

courtyard or other recessed area. The vent cannot

terminate below grade. The bottom of the vent terminal shall

be located at least 12 inches (30cm) above grade and

above normal snow levels. In all cases the appliance shall

be installed in accordance with local codes.

•

The vent outlet MUST NOT terminate below a forced air

inlet at any distance.

•

The vent cannot terminate below grade. Position the vent

termination where vapours will not damage walls or plants

or may otherwise be objectionable.

•

The vent terminal shall not be installed closer than 3 feet (1

m) from an inside corner of an L-shaped structure, window

well, stairwell, alcove, courtyard or other recessed area as

wind eddies could affect boiler performance or cause

recirculation.

•

DO NOT terminate closer than 4 feet (1.25m) horizontally

and vertically from any electric meter, gas meter, regulator,

relief valve, or other equipment. In all cases local codes

take precedence

•

Position terminations so they are not likely to be damaged

by foreign objects, or exposed to a build-up of debris.

•

The vent piping must terminate in an elbow pointed outward

or away from the air inlet.

•

To avoid a blocked flue condition, keep the vent

cap/terminal clear of snow, ice, leaves, debris, etc.

•

Flue gases from this appliance may contain large amounts

of water vapour that will form a white plume in winter. Plume

could obstruct a window view.

•

Flue gas condensate can freeze on exterior walls or on the

vent cap. Frozen condensate on the vent cap can result in

a blocked flue condition. Some discoloration to exterior

building surfaces can be expected. Adjacent brick or

masonry surfaces should be protected with a rust resistant

sheet metal plate.

2.1.5

INLET CAP FOR ROOFTOP TERMINATION

The air inlet cap consists of two 90° elbows installed at the point

of termination for the air inlet pipe. The first 90° elbow is installed

on the rooftop at the highest vertical point of the air inlet pipe

and turned horizontal; the second 90° elbow is screened and is

installed on the horizontal outlet of the first elbow and turned

down. A 90° elbow and a 90° street elbow may be used to make

this assembly. If a straight piece of pipe is used between the two

elbows, it should not exceed 6" (150mm) in length.

2.1.6

LOCATION OF A ROOFTOP AIR INLET AND VENT

CAPS

•

The point of termination for the combustion air inlet cap

MUST be at least 3 feet (0.91M) below the point of flue gas

termination (vent cap) if it is located within a 5 foot (1.5M)

radius of the flue outlet. Use care to ensure that the 90°

elbow assembly is properly installed on the air inlet pipe.

Summary of Contents for Dynaforce Series

Page 2: ...99 0171 REV 0 9...

Page 35: ...35...

Page 48: ...48...

Page 67: ...67 PART 12 EXPLODED VIEW 19 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 20...

Page 68: ...68 21 22 23 24 26 35 34 33 32 31 30 29 28 27 25 36 37 38 39 40 42 43 56...

Page 75: ...75 PART 13 ELECTRICAL DIAGRAMS...

Page 76: ...76...

Page 77: ...77...

Page 78: ...78...

Page 79: ...79...