CBP-436(2017) Operation and Maintenance Manual-CTS Tractors

Camso | 12-17 | 31

Idlers and rollers

Check the general condition of vulcanized midroller and idler wheels.

x

Review the inner side of the wheels where they contact the drive lugs. Excessive wear in

these areas can be caused by continuous hillside work: see the “Proper use,

precautions, not authorized use” section.

x

Look for material imbedded into the surface of the idlers and midrollers. Remove

imbedded objects to prevent damage to the inside surface of the track.

x

Inspect for material build up on the rubber surface. If material build up is related to the

rubber coating worn too thin, replace midroller or idler.

x

Inspect for missing or damaged rubber surface. Replace midrollers or idlers if any of the

following conditions exists:

o

More than 1/3 of the rubber is missing all the way around the wheel

o

Anytime the rubber is missing all the way across the width of the wheel

o

The wheel has a flat spot or does not turn smoothly.

o

The steel core is bent, cracked or damaged

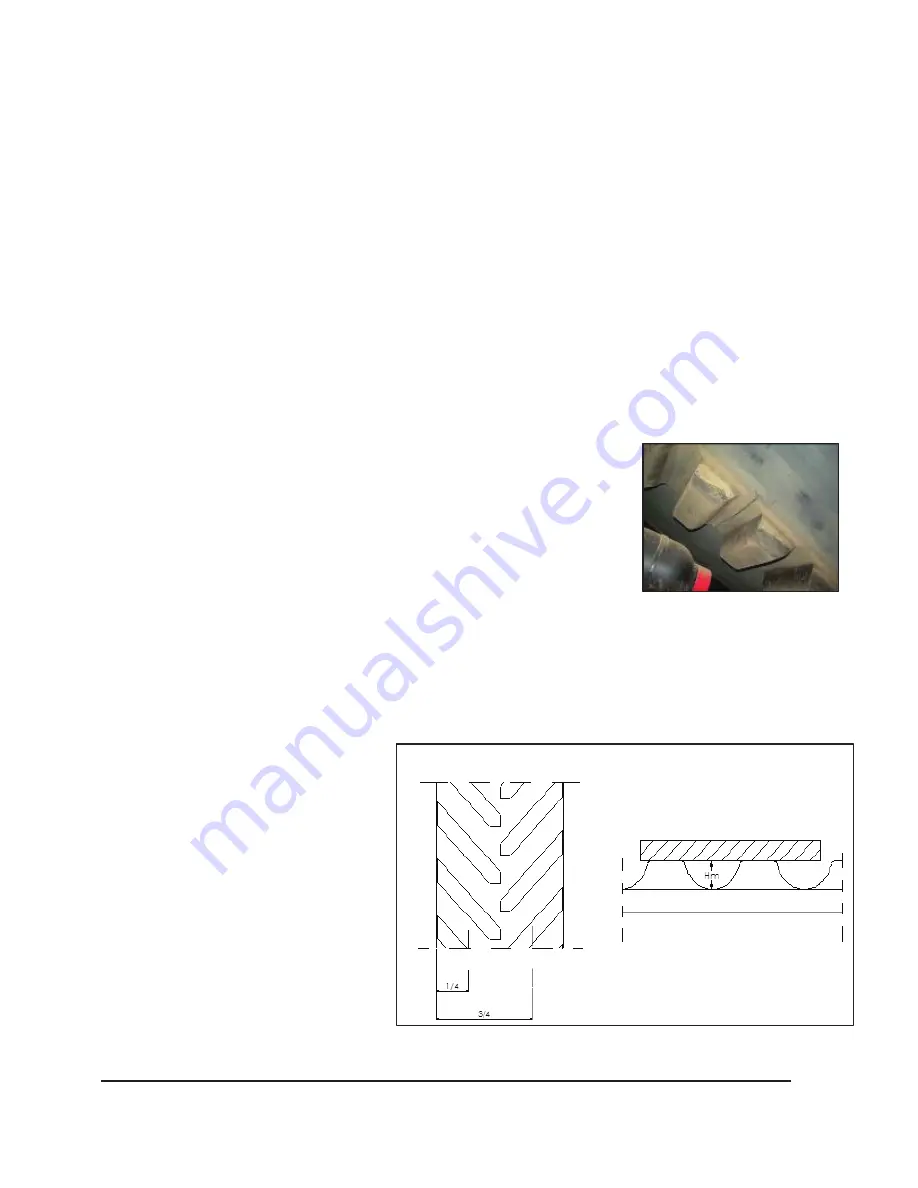

Rubber track drive lugs

Sharp cuts could be visible at the base of track drive lugs, even after a

short work period. This is related to the track bending and the forces

applied to the drive lugs during use on the undercarriage. The cuts are

typically spread randomly and stop growing once they are some

millimeters in depth. These cuts are typical and do not compromise the

performance or life of the track.

Track carcass

Inspect track surface to remove imbedded stones or debris. This contamination can work its way

into the track and damage the steel cable.

Steel wire may come out from the track carcass without affecting the performance of the track.

Remove loose wires by cutting them at the rubber surface.

Track tread

Muddy soils usually cause limited

wear, while roading long distances

can bring about accelerated tread

wear. Due to the crown of the road,

and deflection in the system, the

tread closest to the tractor will tend to

wear faster than the tread on the

outer portion of the track.

Should the height difference between

the tread measured on ¼ and on ¾

of the track width differ averagely of

more than 5 mm (see the picture),

swap tracks side to side on the

machine following the instructions of

“Track exchange side to side”

paragraph in “Scheduled maintenance”

section.