E N G I N E E R E D & P R O C E S S V A L V E S

07/2011 / IOM-GEN-TWIN-03

11

Installation, Operation and Maintenance Manual

GENERAL VALVE

®

Twin Seal

™

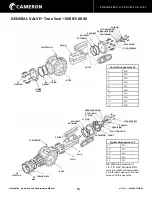

MODEL 375H

Item

No.

375 H

Part No.

Description

Req’d

1

21-419

Operator Housing

1

2

22-417

Upper Stem

1

3

22-418

Lower Stem

1

4

27-418

Indicator Shaft

1

5

27-419

Indicator Flag

1

6

28-406

Handwheel

1

7

45-411

Key

1

8

46-425

Bushing

1

9

48-405

Roller

1

10

50-402

Grease Retainer

1

11

62-32

O-Ring

1

12

64-415

Protector

1

13

64-417

Insignia Plate

1

14

65-402

Grease Seal

1

15

66-409

Ball Bearing

1

16

72-5

Capscrew

4

17

74-6

Screw

1

18

74-9

Set Screw

1

19

75-434

Nut

1

20

76-411

Lube Fitting

1

21

77-407

Guide Pin

1

22

77-423

Drive Pin*

1

23

77-453

Roll Pin

1

24

78-413

Retaining Ring

1

25

78-414

Retaining Ring

1

375 H is Used on Models:

2”

C811

2”

C821

3”

CA811

3”

CA821

OPERATOR DISASSEMBLY

1.

Unscrew (17) and remove indicator flag (5).

2.

Remove the stem protector (12).

3.

Remove the handwheel nut (19),

handwheel (6), key (7) and grease

retainer ring (10).

4.

Remove the retainer ring (25) and pull out

the upper stem (2) with lower stem (3),

bearing (15), roller (9) and indicator shaft

subassembly (4) out through the top of

the housing (1).

5.

Remove set screw (18) from bottom of

lower stem and push indicator shaft sub-

assembly (4) out through the bottom of

the lower stem.

6.

Separate the stems and remove the

retaining ring (24) and the bearing (15)

from the upper stem.

7.

Remove grease seal (14) and bushing (8)

(if required) from top of upper stem (2).

8.

Remove O-Ring (11) from inside housing

.

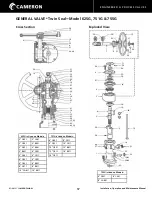

OPERATOR ASSEMBLY

1.

Install O-Ring (11) in housing (1).

2.

Place the bearing (15) on the top of the

upper stem (2). Install retaining ring (24).

3.

Apply a liberal coating of grease to all

surfaces of upper stem (2) and inside and

outside of lower stem (3).

4.

Thread the upper stem and lower stem

together such that the drive pin (22) in the

upper stem comes against the shoulder at

the TOP of the lower stem (3) and the

detent recess in the upper stem is exactly in

line with roller opening in the lower stem.

NOTE: This operation may require several

attempts as the threads are multiple start

and do not always assemble correctly with

the first try.

5.

Install the indicator shaft sub-assembly (4)

up through both stems. Align the detent

hole in the indicator disc with the threaded

hole in the lower stem and fasten with

set screw (18). Set screw must be below the

outside surface of the lower stem.

6.

Place the roller (9) in the side opening of

the lower stem. A liberal application of

grease will hold the roller in position.

7.

Place the stem assembly into the housing

taking care that roller is aligned with roller

groove in housing. Push the entire

assembly down until the bearing rests on

the shoulder in the housing.

8.

Install the retaining ring (25) in the top of

the housing (1).

9.

Install grease retainer (10) in handwheel (6)

and place handwheel and key (7) on upper

stem. Install bushing (8) and grease seal

(14) in handwheel nut (19). Screw the nut

on the upper stem and tighten down on

handwheel securely.

10. Install stem protector (12).

11. Install indicator flag (5) and secure

with screw(17).

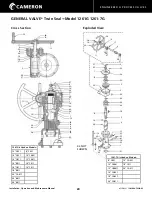

Cross Section

19

17

20

25

15

22

9

18

21

4

5

12

14

8

6

10

24

7

2

3

1

16

23

13

11

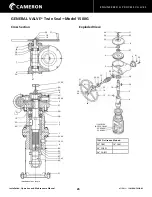

17

5

12

4

19

7

25

10

24

15

22

9

1

2

3

18

21

16

5

8

6

11

Exploded View

* not available separately.