Pa

g.

2

5

25

-

Ma

n

u

al

c

od

e:

11

9

G

U

5

5

11

9

G

U

5

5

ve

r.

0

.2

0.

2

0

3

/2

0

10

© C

A

M

E c

an

ce

lli

auto

m

ati

ci

s.p.a. -

Th

e d

ata a

n

d i

nf

or

m

ati

on r

ep

orte

d i

n th

is

in

sta

lla

tio

n m

an

u

al

a

re s

u

sc

ep

tib

le to c

h

an

g

e at a

ny ti

m

e a

n

d w

ith

ou

t o

b

lig

ati

on

o

n C

A

M

E c

an

ce

lli

auto

m

ati

ci

s.p.a. to n

otify u

se

rs.

ENGLISH

11 Demolition and disposal

In its premises, CAME CANCELLI AUTOMATICI S.p.A. implements an Environmental Management System certifi ed in compliance with the UNI EN ISO 14001

standard to ensure environmental protection.

Please continue our eff orts to protect the environment—which CAME considers one of the cardinal elements in the development of its operational and market

strategies—simply by observing brief recommendations as regards disposal:

DISPOSAL OF PACKAGING – The packaging components (cardboard, plastic, etc.) are all classifi able as solid urban waste products and may be disposed of easily,

keeping in mind recycling possibilities.

Prior to disposal, it is always advisable to check specifi c regulations in force in the place of installation.

PLEASE DISPOSE OF PROPERLY!

PRODUCT DISPOSAL – Our products are made up of various types of materials. Most of them (aluminium, plastics, iron, electrical wires, etc.) may be disposed of

in normal garbage collection bins and can be recycled by disposing of in specifi c recyclable material collection bins and disposal in authorized centres. Other compo-

nents (electrical boards, remote control batteries, etc.), however, may contain polluting substances. They should therefore be removed and given to qualifi ed service

companies for proper disposal.

Prior to disposal, it is always advisable to check specifi c regulations in force in the place of disposal.

PLEASE DISPOSE OF PROPERLY!

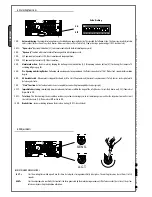

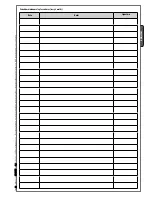

10.3 Problem solving

MALFUNCTIONS

REFERENCES

CHECKS

The unit neither opens nor shuts

1-2-3-4-6-8-18

1 – Close the inspection hatch with the key and check the release lock

The unit opens but does not close

4-7-10

2 - Disable “steady movement” with dipswitch

The unit shuts but does not open

4-7-9

3 – Check power supply and fuses

No automatic closure

11-12-13

4 - N.C. safety contacts open (1-2 / 2-C1 / 2-C5)

The unit does not work if the remote control is used

2-14-16

6 - Disable master-slave function

The unit inverts direction

7-18

7 – Check spring tension and balancing

The unit works only with remote control

22

8 – Disable obstacle detection with dipswitch

The photoelectric cell does not react

12-23-24

9 – Check if end stop opens

The signalling LED indicator flashes rapidly

4

10 – Check if end stop closes

The signalling LED indicator remains on

13

11 - Activate “automatic closure” dip switch

The unit does not end its run

7

12 – Check the correct direction of movement

The bar is not properly balanced

7-15

13 - (2-3 / 2-4 / 2-7) command button

The unit does not slow down

7-15

14 –Check jumper on AF43S, turn on/off power

The unit does not work with the back-up batteries

8-25-26

15 – Check the bar length ratio with mountable accessories

The unit is slow to respond

7

16 – Re-save radio code

18 – Adjust sensitivity

22 - Enter or duplicate the same code in all the remote controls

23 – Activate the photoelectric cell with the dipswitch

24 – Connect the photoelectric cells in a series, not in parallel

25 – Dead batteries

26 –Respect the photoelectric cells’ polarity