14

T

h

e d

at

a a

n

d i

n

fo

rm

at

io

n p

rovi

d

ed

i

n

t

h

is

m

an

u

al

a

re to b

e c

o

n

si

d

er

ed

s

u

sc

ep

ti

b

le to c

h

an

g

e a

t a

n

y t

im

e w

it

h

o

u

t w

ar

n

in

g

, by CAM

E c

an

ce

ll

i a

u

to

m

at

ic

i S

.p

.A

.

ENGLISH

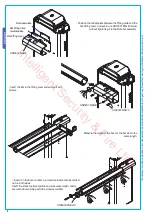

6.1 Periodic maintenance

The unit does not require specifi c maintenance. Only as a precautionary measure and in case of intensive use, we re-

commend periodic checks (every 6 months) on the state of the electric wire connected to the motor, the spring-bar balance, the

tightness of the nuts and the proper oiling of the sliding points between fi xed and mobile parts.

All checks must be recorded (in a dedicated record-book).

6 Maintenance

6.2 Problem solving

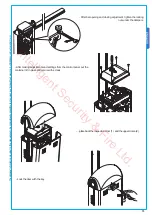

WARNING! The release

procedure may constitute a

hazard for the user when,

for whatever reason – the

bar is fixed improperly to

the housing during assem-

bly, or the bar is cracked or

broken in an accident, and

so on – the tension springs

no longer provide balance!

These can thus cause a

brusque rotation of the bar

attachment and/or of the

bar itself.

5.9 Manual release of the barrier

- Manually raise the bar

and block it again by

turning the key counter-

clockwise.

- Insert the key into the lock and

turn it clockwise.

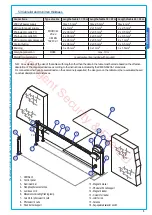

MALFUNCTIONS

REFERENCES

CHECKS

The unit neither opens nor shuts

1-2-3-4-6-8-18 1 – Close the inspection hatch with the key and

The unit opens but does not close

4-7-10

2 - Disable “steady movement” with dipswitch

The unit shuts but does not open

7-9

3 – Check power supply and fuses

No automatic closure

11-12-13

4 - N.C. safety contacts open (1-2 / 2-C1)

The unit does not work if the remote control

is used

2-14-16

6 - Disable master-slave function

The unit inverts direction

7-18

7 – Check spring tension and balancing

The unit works only with remote control

22

8 – Disable obstacle detection with dipswitch

The photoelectric cell does not react

12-23-24

9 – Check if end stop opens

The signalling LED indicator flashes rapidly

4

10 – Check if end stop closes

The signalling LED indicator remains on

13

11 - Activate “automatic closure” dip switch

The unit does not end its run

7

12 – Check the correct direction of movement

The bar is not properly balanced

7-15

13 - (2-3 / 2-4 / 2-7) command button

The unit does not slow down

7-15

14 –Check jumper on AF43S, turn on/off power

The unit does not work with the back-up

batteries

8-25-26

15 – Check the bar length ratio with mountable accesso-

ries

The unit is slow to respond

7

16 – Re-save radio code

18 – Ad just the trimmer

22 - Enter or duplicate the same code in all the remote controls

23 – Activate the photoelectric cell with the dipswitch

24 – Connect the photoelectric cells in a series, not in parallel

25 – Dead batteries

26 –Respect the photoelectric cells’ polarity

Intelligent Security & Fire Ltd.