3

T

h

e d

at

a a

n

d i

n

fo

rm

at

io

n p

rovi

d

ed

i

n

t

h

is

m

an

u

al

a

re to b

e c

o

n

si

d

er

ed

s

u

sc

ep

ti

b

le to c

h

an

g

e a

t a

n

y t

im

e w

it

h

o

u

t w

ar

n

in

g

, by CAM

E c

an

ce

ll

i a

u

to

m

at

ic

i S

.p

.A

.

ENGLISH

14

CAME

CAME

CAME

CAME

:,

12

8

1

2

3

4

5

6

6

11

10

7

8

9

13

1

2

3

5

4

12

7

9

11

13

10

13

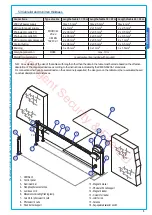

4.2 Technical information

#

#

4.3 Parts description

AUTOMATION UNIT

ACCESSORIES

VIEW FROM THE BAR

SUPPORT BRACKET

VIEW FROM INSPECTION

HATCH

GEARMOTOR

Power supply: 230V A.C. 50/60Hz

Motor power supply: 24V D.C. 50/60Hz

Max. absorption: 1.3A (230V) / 15A (24V)

Rated power: 300W

Max. torque: 600 Nm

Reduction ratio: 1/202

Opening time: 4÷8 s

Operative intermittence: intensive operation

Protection level: IP54

Weight: 90 kg

Insulation class: I

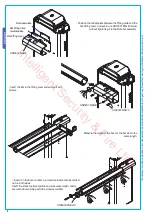

1)

G02000/G04000 - aluminium bar, painted white, Ø 100 mm

2)

G02040 - Ø40 (yellow) balancing spring

3)

G04060 -Ø50 (green) balancing spring

4)

G06080 - Ø55 (red) balancing spring

5)

G02806 - Rack

6)

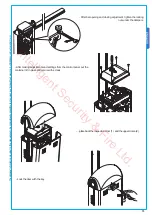

G02802 - Support for DIR photoelectric cells

7)

G02803 - Luminous cord

8)

G02807 - Fixed barrier support

9)

G02808

- Mobile barrier support

10)

G02809 - Adhesive reflector strips

11)

G02801 - Flashing dome lamp

12)

G02805 - Emergency battery housing support

13)

ZL38 - Electric board designed to accommodate radio board coupling

14)

G06803 - Telescopic joint and additional insert to attach the bar

1) Upper dome

2) Bar beam plate

3) Bar fitting intermediate plate

4) Cover for aluminium bar

5) Anti-shearing protection cover

6) Sheet-steel or stainless steel cabinet with

galvanized and painted finish

7) Features for housing accessories

8) ABS container for electric

board with transformer

9) End-stop assembly

10) Lever arm

11) Transmission rod

12) Inspection hatch

13) Bar position adjustment buffers

14) Gearmotor

Intelligent Security & Fire Ltd.