{

{

{

8

8

8

10”

1”

p.

19

- M

anu

al

FA

0

1

2

0

6

-E

N

- 0

6

/2

0

18 - © C

A

M

E S

.p

.A

. - T

ransla

te

d o

riginal inst

ru

ct

io

ns

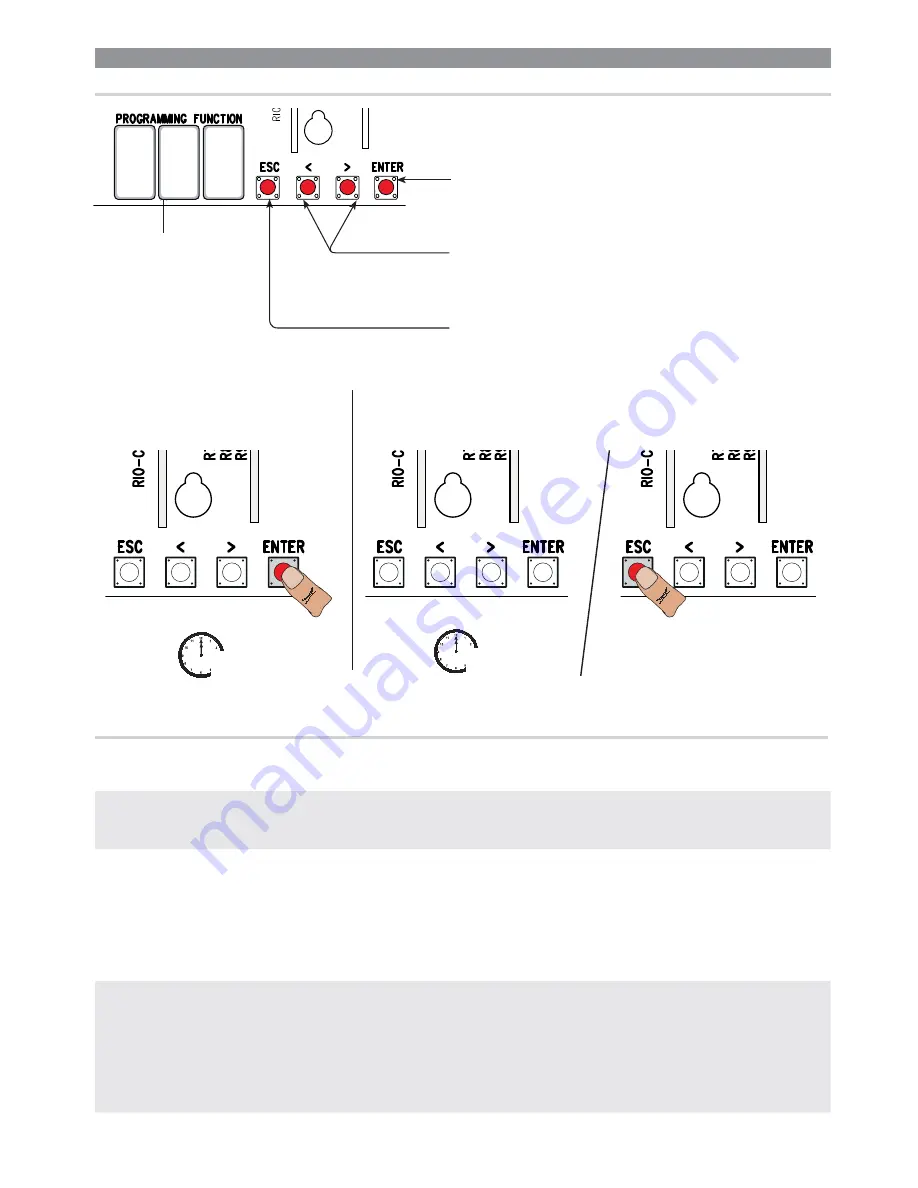

The < > keys are for:

- moving from one item to another;

- increasing or decreasing a value;

- opening and closing the gate (only when testing).

The ESC button is for:

- exiting menus;

- deleting changes;

- stopping the gate (only when testing).

The ENTER key is for:

- entering menus;

- confirming or memorizing set values.

To exit the menu, wait 10 seconds or press ESC.

To enter the menu, keep the ENTER button

pressed for at least one second.

Display

PROGRAMMING

DESCRIPTION OF THE COMMANDS

F1

Total stop [1-2]

NC input – Gate stop that excludes any automatic closing; to resume movement, use the control device. The

safety device is inserted into (1-2). If unused, select 0.

OFF

(

default

) /

ON

F2

Input [2-CX]

NCinput – Can associate: C1 = reopening during closing by photocells, C2 = reclosing during opening by

photocells, C3 = partial stop, C4 = obstruction wait, C7 = reopening during closing by sensitive safety-edges

(with clean contact), C8 = reclosing during opening by sensitive safety-edges (with clean contact), r7 =

reopening during closing for sensitive safety edges (8K2 resistive input), - r8 = reclosing during opening for

sensitive safety edges (8K2 resistive input).

The C3 Partial stop function only appears if the F 19 Automatic closing time function is activated.

OFF

(

default

) /

1

=C1 /

2

=C2 /

3

=C3 /

4

=C4 /

7

=C7 /

8

=C8 /

r7

=r7 /

r8

=r8

F3

Input [2-CY]

NC input – Can associate: C1 = reopening during closing by photocells, C2 = reclosing during opening by

photocells, C3 = partial stop, C4 = obstruction wait, C7 = reopening during closing by sensitive safety-edges

(with clean contact), C8 = reclosing during opening by sensitive safety-edges (with clean contact), r7 =

reopening during closing for sensitive safety edges (8K2 resistive input), - r8 = reclosing during opening for

sensitive safety edges (8K2 resistive input).

The C3 Partial stop function only appears if the F 19 Automatic closing time function is activated.

OFF

(

default

) /

1

=C1 /

2

=C2 /

3

=C3 /

4

=C4 /

7

=C7 /

8

=C8 /

r7

=r7 /

r8

=r8

⚠

When programming, the operator needs to be in stop mode.

FUNCTIONS MENU