Page 14

Page 15

Once the lid or side panel are removed, access to the Service Area

has been gained. This access must be restricted to persons having

knowledge and practical experience of the appliance, in particular as

far as safety and hygiene are concerned.

De-scale

Note

: Whenever the body lid has been removed from the boiler a new lid

gasket will be required to ensure a steam-tight joint. Damage to the unit

caused by a poor lid seal is not covered under the warranty of the unit.

Scale deposits should be removed from all internal surfaces, particularly

the heating element and thermistor’s, by gently tapping or scraping. If

the deposits are soft, use a nylon pad and flush out. Abrasive cleaning

materials containing scouring powders and detergents must not be used,

such materials can cause taste problems. Chemical de-scalants must only

be used in accordance with the manufacturer’s instructions.

Basic operation

The water-fill and heat functions of the CB boiler are completely

independent of each other.

Heater function

The printed circuit board (PCB) controls the heating function of the boiler

by monitoring the top and bottom thermistors, the safety cutout and

the economy switch. The function of this switch is to bring the bottom

thermistor in or out of circuit. In the ‘ECON’ position, the bottom thermistor

is ignored resulting in a reduced volume of water being maintained

at operating temperature. In the ‘MAX’ position, both thermistors are

monitored and a larger volume of hot water is available for use at any one

time. The PCB also controls the external light unit to indicate when the

water is at the correct temperature: green for ready (i.e. top thermistor

satisfied), red for wait (i.e. water below temperature). If both lights are

displayed together, the low water safety cutout has tripped, or some

section of its circuit has become open. This would occur either because

the machine has been switched on without first allowing it to fill with

water, (and the element has energised in air), the safety cutout is faulty

(and should be replaced), or there is a poor contact at the PCB connector

pins. Removing and re-fitting the connector usually remedies the latter

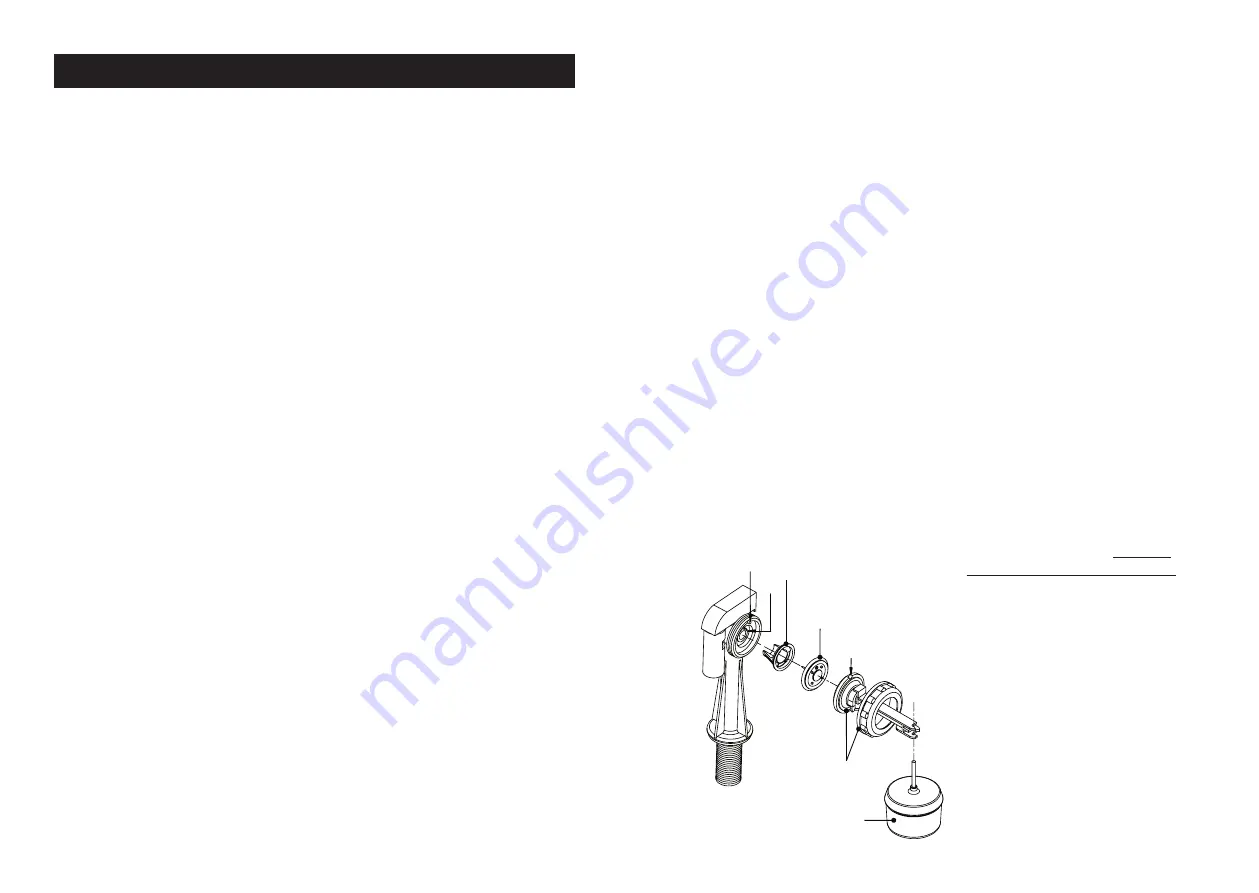

Diaphragm (FVD)

Central pin pointing

towards valve body

Filter (FVF)

Cutout

Locating boss

(FVAFC)

Float (FVFL)

Pin

Float arm

& cap

fault. The possibility also exists that the setting of the cutout has been

turned down. These are factory set to 120°C, but turning it down below

100°C would cause it to constantly trip. The red LED on the PCB will

flash when first energised indicating program initialisation. There after

the LED indicates ‘Neutral’ switched to element. Note: the element has a

permanent ‘Live’ feed.

Should an element fail and need to be replaced, it is necessary to replace

the four-piece lid gasket to ensure a reliable steam-seal.

In the event of a PCB failing and a replacement being required, full

instructions will be supplied. It is important to note, however, that the

integral Triac must be securely mounted against the copper heat-sink /

mounting bracket to ensure reliable heat dissipation.

Water-fill function

A Torbeck float valve controls the water level in the cold water tank, which

feeds the main boiling chamber (referred to as the ‘body’). This is generally

a reliable component, but problems can arise if the incoming water supply

contains debris. Occasionally, dirt can pass through the internal filter and

become lodged on the diaphragm, causing the valve to weep. This can

be remedied by dismantling the valve (as shown opposite) and gently

cleaning the diaphragm with fresh water. When re-assembling the valve,

the diaphragm must be re inserted with its central pin facing into the body

of the valve and with the pin on the body passing through the hole in the

diaphragm. Before tightening the nut, ensure that the cut-out in the float

arm is positioned around the locating boss on the valve body. The nut

should be hand-tightened only.

Note: The valve can take up to

15 seconds to fully close after

the float arm is raised. This is

a normal feature of the valve

and is intended to reduce the

effects of water / pipe hammer

For assistance with any aspect of

the machine, please call Calomax

directly on 0113 249 6681 or

e-mail [email protected]

SERVICE INSTRUCTIONS