REGUL8OR – User’s Manual

26

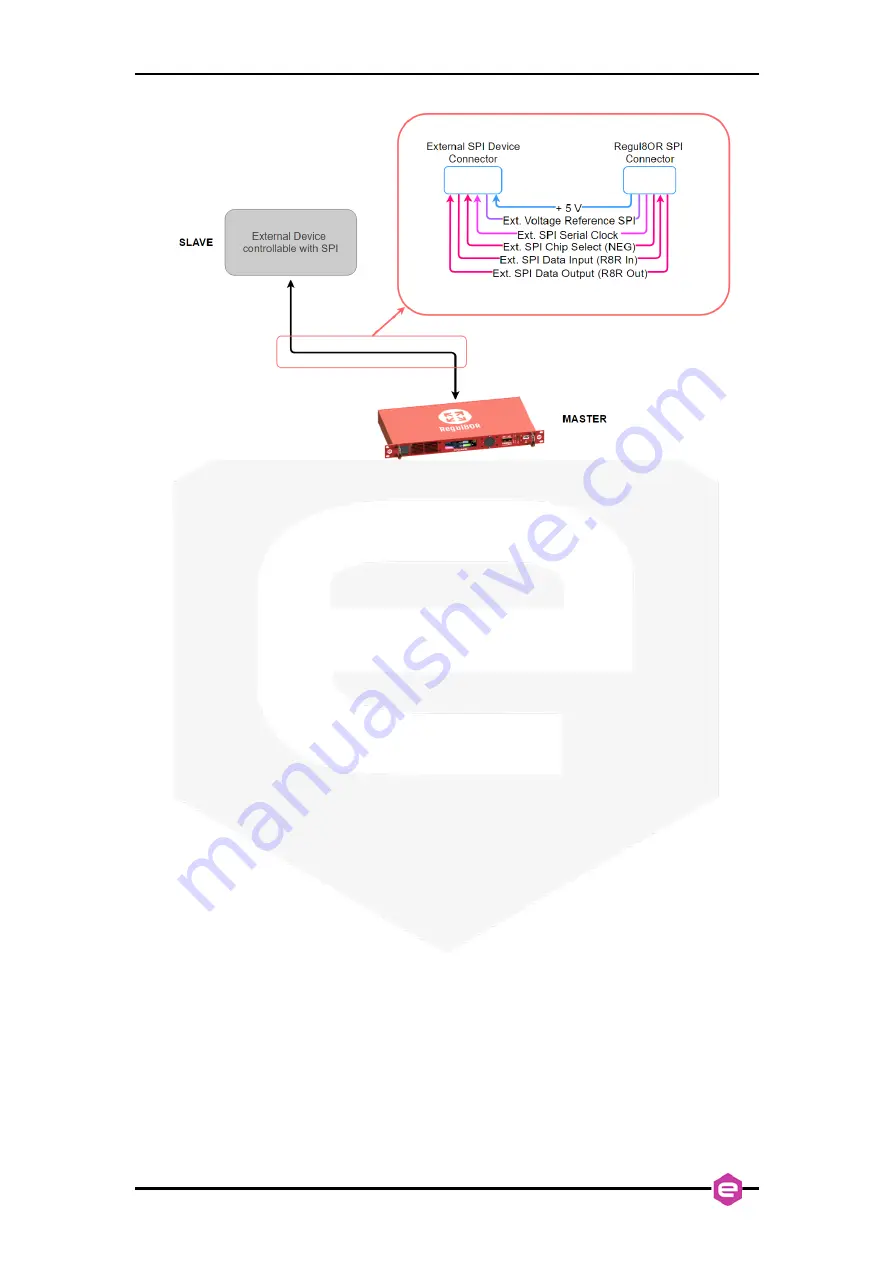

Figure 10:

schematic representation of a connection between the Regul8OR and a generic external

device made with the SPI

1.9

Output Connectors

The REGUL8OR has been designed to control an external power

stage/programmable power supply with an analog output voltage or, in specific cases,

an analog output current (to close a 4-20 mA loop).

Two connectors, an isolated BNC (voltage output) and a 4-pin LEMO (current

path and voltage output), are provided on the rear panel to feed the isolated output

signals.

Typically, a general-purpose programmable power supply can be controlled via

an external analog voltage with typical values ranging from 0 V to 10 V or from 0 V to

5 V (unipolar operation). In some specific applications, these signals can range from -

10 V to +10 V or from -5 V to +5 V (bipolar operation).

The analog output voltage is generated by a state-of-the-art 20-bit 1-MSPS

Digital to Analog Converter (DAC).

The 4-20 mA current control loop is often used in industrial process control. Its

name refers to the current range used to control or to measure in the loop, where the

current spans from a minimum value of 4 mA (0 %) to a maximum value of 20 mA

(100 % or full-scale). The main reason for the use of this current-based signal has to be

found in the fact that current signals are less sensitive to noise than voltage signals and

are so sometimes preferred in noisy environments – e.g. industrial facilities. The chosen

loop driver is a single-channel, 16-bit converter.