7

2.3

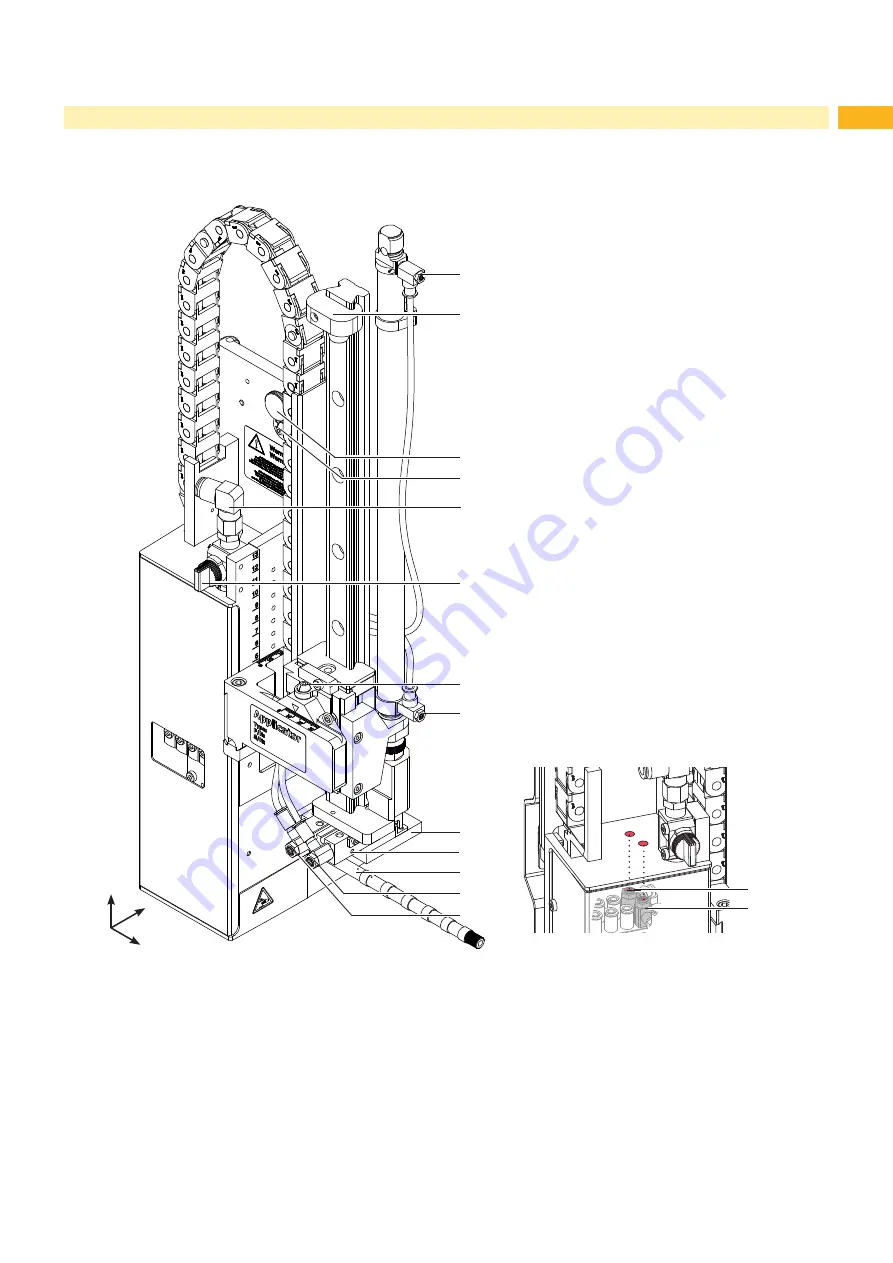

Overview without Cover

1

2

3

4

5

6

7

8

9

11

12

13

10

support air

vacuum

14

15

Fig. 2

Overview - front view

1 Stopper for the operation mode "Blow on",

transport lock

2 Throttle valve cylinder - move in Z-direction

3 Knurled screw for attaching the applicator to the

printer

4 Setting screw to adjust the angle between appli-

cator and printer

5 Compressed air connector

6 Shutoff valve

7 Setting screw for vertical adjustment cylinder

assembly

8 Throttle valve

cylinder - move out Z-direction

9 Pad - customized

10 Cylinder Y

11 Blow tube for supporting air

12 Throttle valve cylinder - move out Y-direction

13 Throttle valve cylinder - move in Y-direction

14 Support air throttle valve

15 Vacuum throttle valve

Front view

Throttle valves vacuum/support air

y

x

z

Summary of Contents for 4114 Series

Page 1: ...Made in Germany 4114 4116 Stroke Applicator Service Manual ...

Page 40: ...40 40 11 Drawings 11 2 Pneumatic Drawing Type 4114 Fig 41 Pneumatic drawing type 4114 ...

Page 41: ...41 11 Drawings 11 3 Pneumatic Drawing Type 4116 Fig 42 Pneumatic drawing type 4116 ...

Page 42: ...42 42 11 Drawings 11 4 Label Position Type 4114L 4116L Fig 43 Label position 4414L 4116L ...

Page 43: ...43 11 Drawings 11 5 Label Position Type 4114R 4116R Fig 44 Label position 4114R 4116R ...