10. Tie a knot loop approximately 12” down on the new replacement line. Grasp

the line and pull it towards the knot loop behind the nozzle. Untwist the portion

of webbing between the nozzle and the screwdriver that secures the webbing.

Check that the screwdriver is still vertical, and has not rotated during line

replacement. If so, reorient the screwdriver to its original position. Also check

that the black mark is still on the upper portion of webbing.

13. Extract the line and untie the knot loop. A second pair of hands will be

required to help secure the webbing. Return the new line into the housing

slowly, in a controlled manner, while maintaining a secure grip on the line.

14. Inspect prior to use by extracting all of the line, and returning it once again to

the housing. Check for smooth operation and proper line retraction.

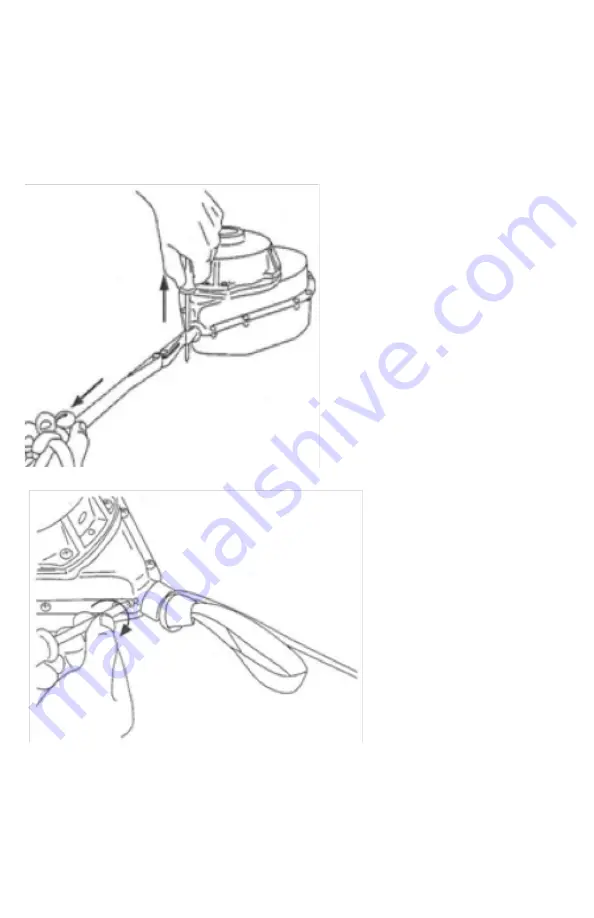

11. With the nozzle slot oriented

vertically, and no twists in the line,

apply tension to the nozzle and

knot loop while removing the duct

tape and screwdriver that secured

the webbing

(Figure 11). Feed the

line back into the housing until the

nozzle and knot loop are against

the housing. Press the nozzle into

the housing so that the nozzle slot

remains vertical, and the nozzle

screw hole is aligned with the

housing screw hole. Again make

certain that the webbing has not

twisted as the nozzle is installed.

12. Install the sheet metal screw

through the housing screw hole

and into the nozzle screw hole

(Figure 12). Tighten the screw

until snug. Avoid over-tightening,

as you may strip the threads of the

nozzle.

Figure 11

Figure 12

10.

11.

12.

13.

14.