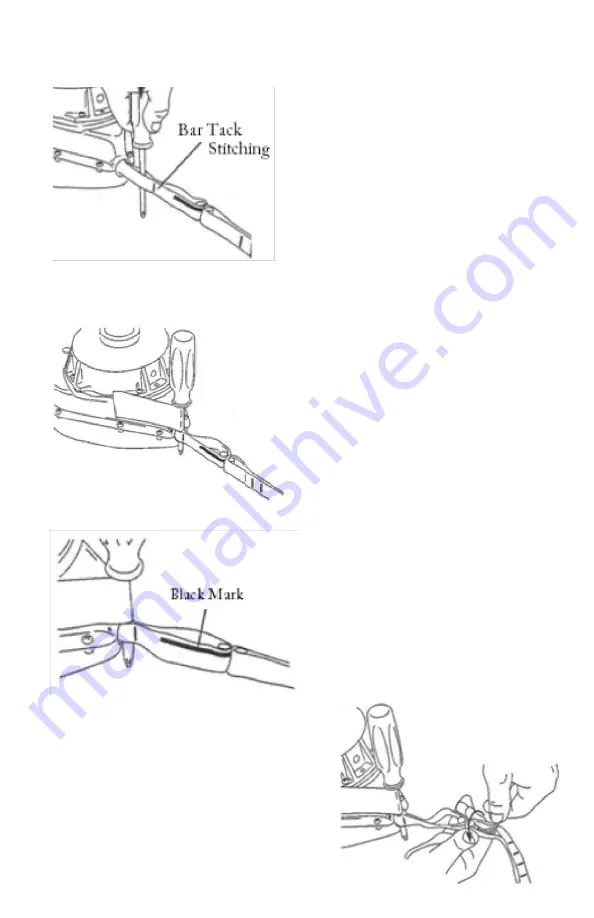

5. Using a 5/16 inch Allen wrench,

remove the webbing joint bolt

(Figure 7).

Figure 4

Figure 5

Figure 6

Figure 7

4. Secure the line by inserting a

Phillips head screwdriver between

the two layers of blue webbing

where indicated in

Figure 4. To

prevent twisting it is important that

the webbing maintain its vertical

orientation (screwdriver oriented

vertically). The screwdriver will

prevent the joint from returning into

the housing during replacement.

Release the webbing, making

certain that the line is adequately

secured, and that the screwdriver

will not slip loose or rotate.

Place some duct tape across the

screwdriver and housing nose to

prevent the screwdriver and line

from twisting

(Figure 5). If the

detached end of the line retracts and

is lost within the housing, the Perfect

Descent will require factory repair.

A black mark should appear on

the upper portion of the web

(Figure 6). If not, the webbing

has become twisted. Untwist the

webbing by carefully examining the

webbing as it exits the housing and

rotating the webbing so the mark

appears in its proper location.

4.

5.