ConneX1 Operator’s Manual

15

+'

Startup Message:

Enter text to display on the detector LCD during startup (25

characters maximum).

4.1.2 ,

For more information, refer to

5. Mandown Alarm on page 19

.

Enable Mandown Feature:

If enabled, the detector alarms if movement is not

detected after a certain time period. The time period is defined in

Mandown Timeout

.

Mandown Idle Time:

Defines how long no motion must be detected before a

Mandown alarm (10 to 240 seconds). The default value is 10 seconds.

Mandown Sensitivity:

Define the sensitivity of the detector accelerometer. 100

equals high sensitivity and 0 equals low sensitivity.

4.1.3 ',

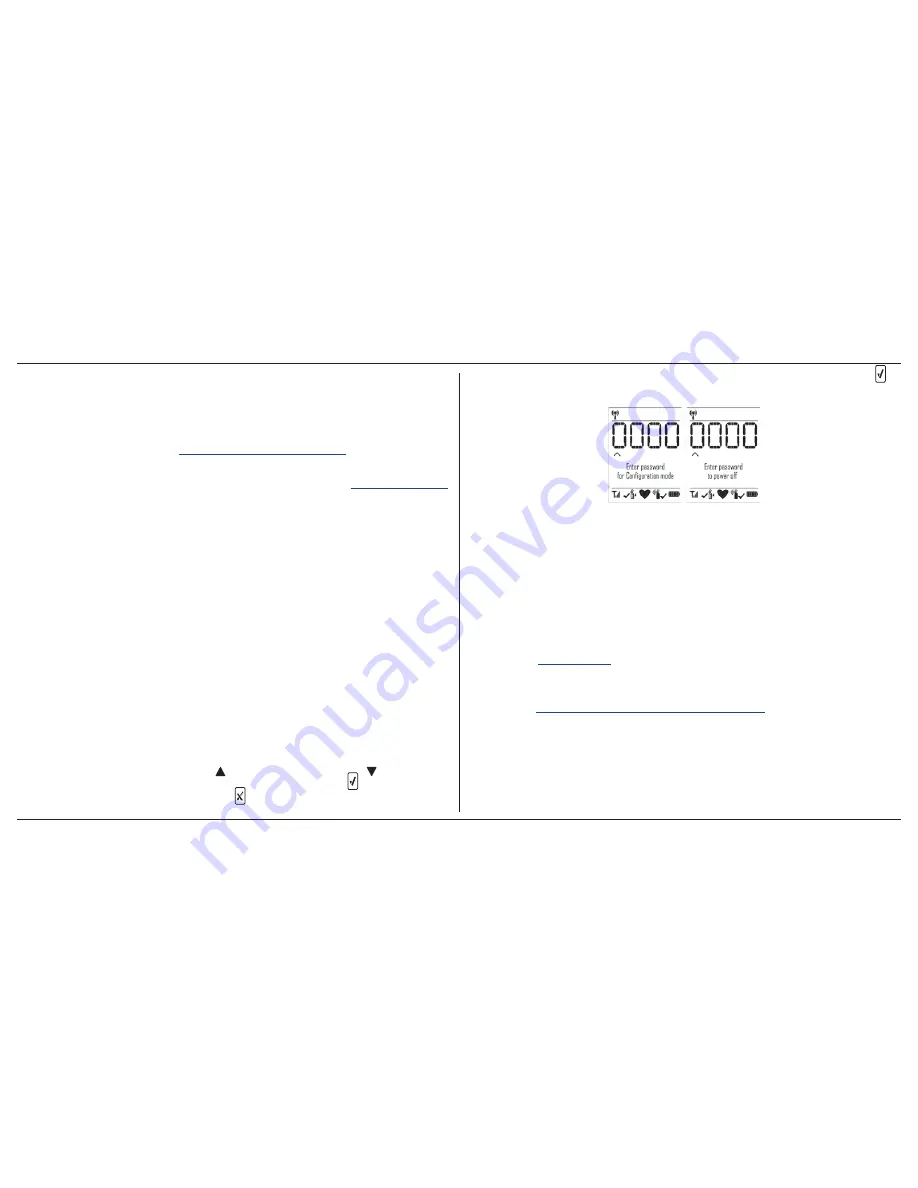

"# ',!

When enabled, a password must be entered

to to enter Configuration Menu on the detector. The detector is shipped with the

password disabled.

Enable Password Protection for Device Shutdown:

When enabled, a password

must be entered to deactivate the detector. The detector is shipped with the

password disabled.

Password:

Set the 4-digit password.

4.1.3.1 Entering a Password

To enter the password on the detector. Complete the following procedure.

1.

Change the digit by pressing to increment the digit and to decrement

the digit. Move the cursor to the next digit by pressing . Move the cursor

to the previous digit by pressing .

2.

When at the last digit and the correct number is selected, press to

enter the password.

4.2 +'

A profile is a set of configuration options which allows the user to quickly change

the configuration and behaviour of the instrument, depending on the situation.

4.2.1 ' -$

$$&$!

If enabled, every time a button is pressed, the beeper sounds.

The detector is shipped with the beep per key press enabled. Beep per key press

is disabled if

Stealth Mode

is enabled.

$!

If enabled, the Confidence Beep provides continuous audible

confirmation that the detector is operating correctly. Frequency of the beep is

defined with

Confidence Beep/Flash Interval (seconds)

.

Summary of Contents for CONNEX1

Page 1: ...Gas Detector Operator s Manual...

Page 2: ......

Page 7: ...ConneX1 Operator s Manual v...

Page 8: ...ConneX1 Operator s Manual vi...

Page 9: ...ConneX1 Operator s Manual vii...

Page 71: ......

Page 72: ...D6657 0 50104992 032 BW Technologies by Honeywell 2012 All Rights reserved...