- 14 -

4. Maintenance and Repair

Important

:

Before executing maintenance and repair works, always first unplug from the mains!

−

During the operation of the ball machine, make sure that no small parts (for example hairs, in-

dented balls, etc.) get into the collection net and thus into the machine, because they can lead to

ball jams.

−

The ball shooting discs are very durable (at least 500 hours). Nevertheless, these discs will finally wear

off after intense use. One sign for a worn disc is that the machine releases the balls at irregular lengths at

high speed. This means that the surface of the discs does not have enough grip on the balls. For that rea-

son, the distance of the discs has to be adjusted.

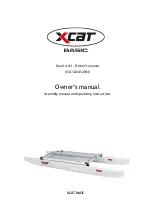

Put the plastic adjusting tube in the release hole found between the discs

(Fig. 13.)

. Loosen first, for ex-

ample, the black imbus “adjusting” screw near the cover- with the bigger allan key found among the ac-

cessories - of he lower motor

(Fig. 14.)

and turn up the motor (gripping its cover) towards the adjusting

tube until the disc touches it.

(Fig. 15.)

Do all this also with the other two motors.

Please note

:

The correct distance is 35-36 mm. This is the diameter of the adjusting tube. The release

mechanism functions perfectly up to a distance of 37-38 mm

.

−

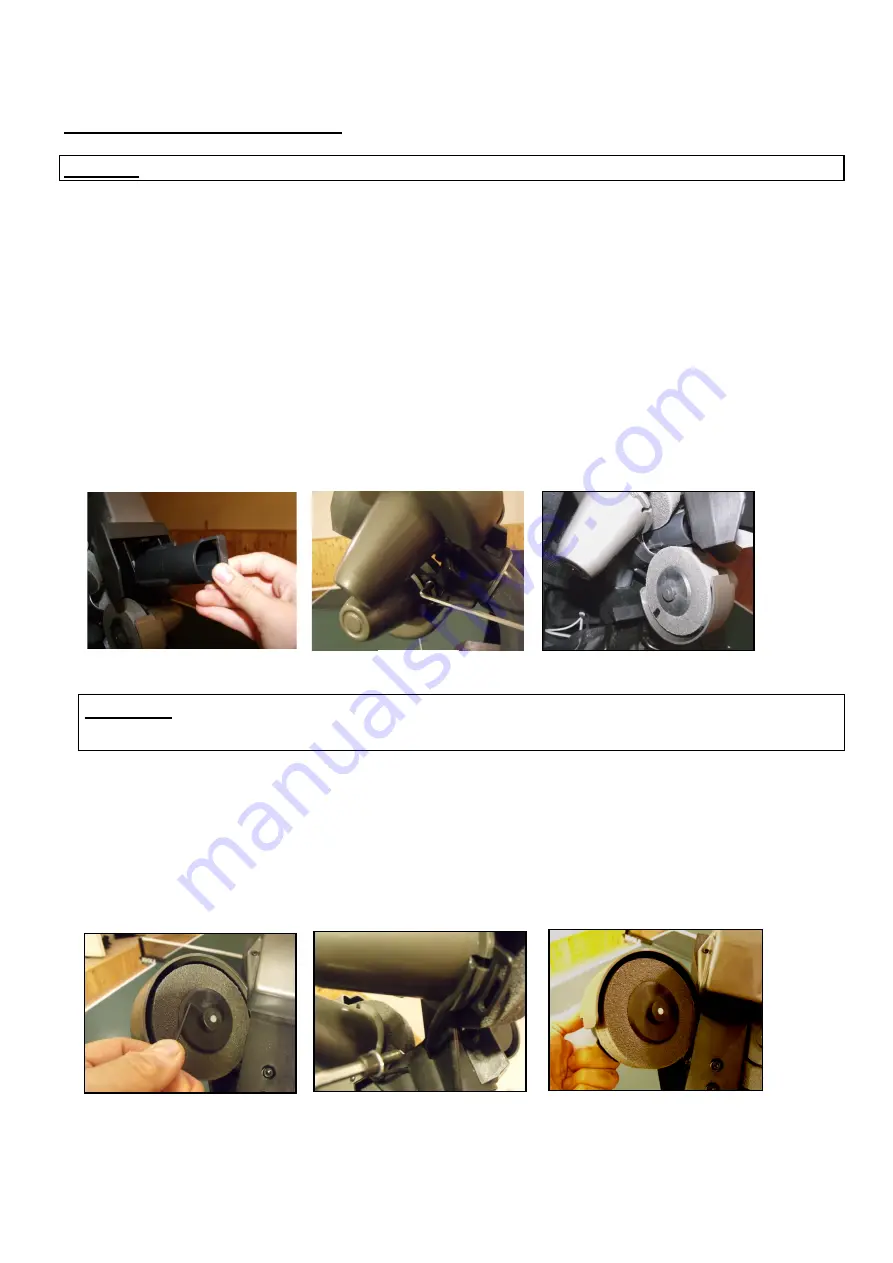

When the distance cannot be adjusted anymore, the ball throw discs have to be replaced. Therefore

loosen the screws

(Fig.16.)

found in the plastic disc holders – with the smaller allan key found among

the accessories - (regarding all 3 discs), then remove the “adjusting screws” found at the two upper

motors (it is not enough only to loosen those)

(Fig. 17.)

Then totally turn up the two upper motors grip-

ping their casings and turning those away from the throwing hole in order to make possible the pull

down of the throw discs from the shafts of the motors.

(Fig. 18.)

Fig. 12.

Fig. 13.

Fig. 16.

Fig. 15.

Fig. 16.

Fig. 13.

Fig. 14.

Fig. 15.

Fig. 17.

Fig. 18.

Fig. 17.

Fig. 18.