burster Italia s.r.l. · Sede legale ed operativa · Via Cesare Battisti, 16/18 · 24035 Curno (BG) · Tel. +39 035 618120 · Fax +39 035 618250

e-mail: [email protected] · http://www.burster.it

C.F. e P.IVA 11048400151 · Capitale sociale Euro 49.920,00 · R.E.A. di Bergamo 276749

Apparecchi di misura di precisione. Sensori e Sistemi

per grandezze elettriche, termiche e meccaniche

3.2

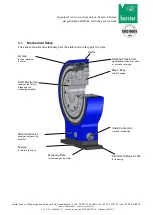

Electrical Setup

The electronics integrated in the sensor consistsof two parts.

The first part is in the stator and has following tasks:

Stabilization of the supply voltage

Electric supply of the rotor electronics through the rotating transformer

Preparation of the measurement signal from the rotor

Transmission of the torque measurement signal to the cable connection

The second part of the electronics is placed in the rotor of the torque sensor

with following functions:

Supply of the SG full bridge with DC voltage

Preparation of the electrical torque measurement signal

Transmission of the measurement signal to the stator

4

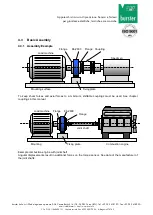

Mechanical Assembly

4.1

Rotor Assembly

Caution:

During the assembly inadmissibly large forces may not act on the sensor or the

couplings. Connect the sensor electrically during the assembly and observe the signal, the

measurement signal may not exceed the limit values.

To avoid falling down, the sensor must be supported during the assembly.

Admissible assembly offset from rotor to stator:

4.2 Stator Assembly

The sensor is installed into the shaft string through flanges. Prior to the assembly, flanges must be

cleaned with solvent (e.g. acetone), they must be free of foreign particles. The surface of the flange must

have an evenness of minimum 0,02 mm.

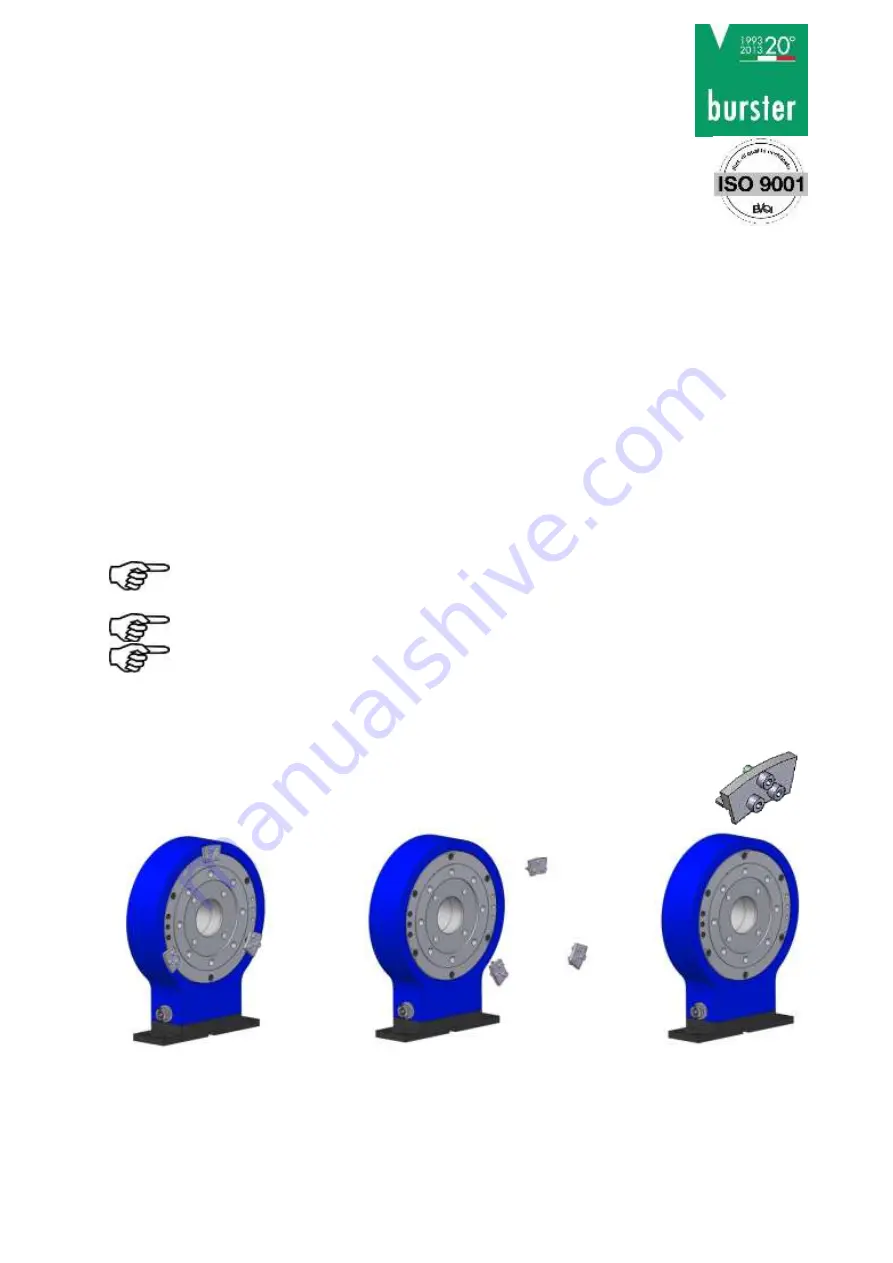

For transportation and easier assembly, the torque sensor is delivered with fixing plates.

The optimal

axial position of Stator to Rotor

is defined by fixing plates.

(per plate 3 screws M4x10)

Mounted Fixing Plates

Removed Fixing Plates

Without Fixing Plates

Tighten screws evenly on the flanges. Torque transmission by surface pressure, only. The installation and

alignment of the torque sensor occurs with mounted fixing plates.

Use appropriate tightening torques for the screws of

strength 10.9

with suitable length. The screws

should be secured with screw locks (e.g. LOCTITE No. 242).