burster Italia s.r.l. · Sede legale ed operativa · Via Cesare Battisti, 16/18 · 24035 Curno (BG) · Tel. +39 035 618120 · Fax +39 035 618250

e-mail: [email protected] · http://www.burster.it

C.F. e P.IVA 11048400151 · Capitale sociale Euro 49.920,00 · R.E.A. di Bergamo 276749

Apparecchi di misura di precisione. Sensori e Sistemi

per grandezze elettriche, termiche e meccaniche

5.2

Cable

Only use a shielded cable with minimum capacity. We recommend measuring cables from our product

range. They have been tested in combination with our sensors and meet the metrological requirements.

5.3

Shielding Connection

In combination with the sensor and the external electronics, the shield forms a Faraday Cage. By this,

electro-magnetic disturbances do not have any influence on the measurement signal.

5.4

Installation of Measuring Cables

Do not lay measuring cables together with control lines or power cables. Always assure that a large

distance is kept to engines, transformers and contactors, because their stray fields can lead to

interferences of the measuring signals.

If troubles occur through the measuring cable, we recommend to lay the cable in a grounded steel

conduit.

5.5

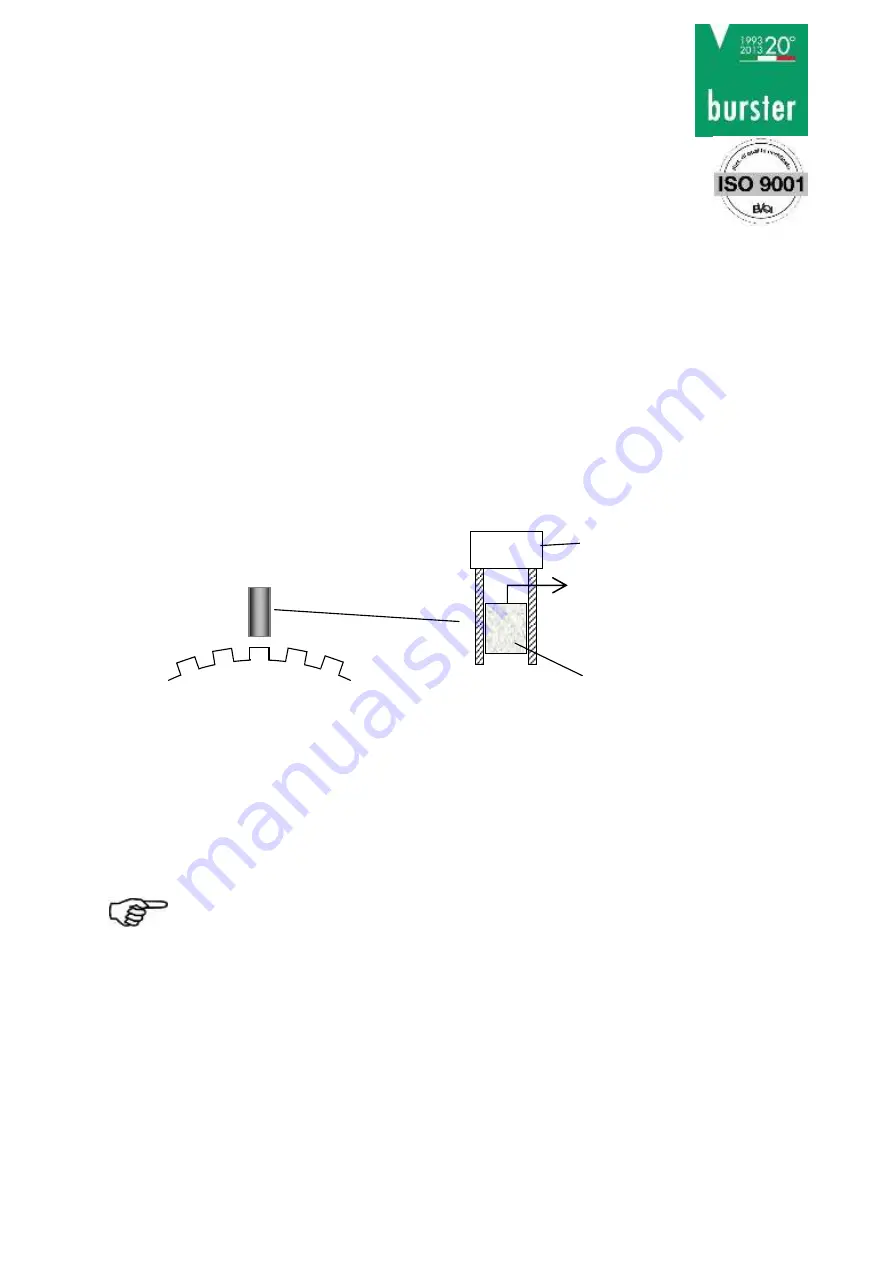

Speed Sensor (Option)

A hall sensor is located between the pulse wheel and the permanent magnet. If a tooth of the pulse wheel

passes the energized hall sensor, the field intensity of the permanent magnet changes. By this, hall

voltage occurs which is processed to a rectangular signal by the integrated evaluation electronics.

6

Measuring

6.1

Engaging

The warming-up period of the torque sensor is approx. 5 min. Afterwards the measurement can be

started.

The warming-up period of the torque sensor is approx. 5 min.

6.2

Direction of Torque

Torque means clockwise torque if the torque acts clockwise when facing the shaft end. In this case a

positive electrical signal is obtained at the output.

Torque sensors by burster can measure both, in clockwise and counter-clockwise direction.

6.3

Static / Quasi-Static Torques

Static and/or quasi-static torque is a slowly changing torque.

The calibration of the sensors occurs statically on a calibration device.

The applied torque can accept any value up to the nominal torque.

Pulse wheel

(ferromagnetic)

N S

Permanent magnet

Hall-probe

Output signal