7

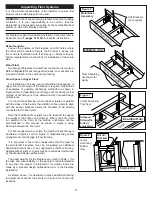

Clearance to Combustibles

The distance to be maintained from the surfaces of the

fireplace to combustibles must be observed. Below is a list of

the most common combustible materials to name a few:

Drywall

Wood flooring

Plywood

Sub-flooring

Wood Framing

Particle board

Mill board

Plywood paneling

Maintain the following minimum clearances:

Unit front, sides, rear

0”

0

Combustible floor

0”

0

Sheathing or trim to opening sides

8” (203 mm)

Combustible sheathing above opening top

8” (203 mm)

Mantel above opening

12” (305 mm)

Opening to side wall

20” (508 mm)

Insulation from firebox

0”

0

Due to high temperatures, never install this fireplace in a

recreational vehicle, in high traffic areas, drafty areas, or

where curtains, furniture, clothing, or other flammable objects

are less than 36” from the front or side and 42” from the top of

the fireplace.

CAUTION: This gas fireplace attains high temperatures. Keep

children and adults away from hot surfaces to avoid ignition of

clothing and/or burns. Even after the fireplace is shutdown it

will remain hot for a time afterward. Allow the surface to cool

before touching it.

Carefully supervise young children when they are in the room

with the fireplace.

All fireplace openings for both combustion air and exhaust

must remain open and unobstructed at all times when the

fireplace is in operation.

The Burntech® fireplace has been designed, tested and

approved for zero clearance to combustible floors.

Be certain that the Burntech® fireplace is installed with the

finished fire brick floor of the fireplace so that it is at least 4-1/2”

(four and a half inches) above the combustible floor system.

Warning to the structural engineer and/or building contractor:

It is your responsibility to be certain that the fireplace can be

properly supported by the combustible floor system on which

the fireplace will rest. Be advised that this engineering equation

will be in addition to any live or dead weights that the floor has

to carry.

Burntech® Fireplace & Chimney Systems

Before Getting Started…

Even if you consider yourself an expert in the field of

fireplace installation, we at

Burntech®

caution you to take the

time to totally familiarize yourself with the instructions to

follow.

We can assure you that there will be information that will

make the installation go smoother and, above all, safer, for

everyone concerned. At the least, reading these procedures will

save you time and, at the most, it will prevent any malfunction

that could result in property damage or serious injury.

Do not start the installation until you have checked out all

the local, regional, state and national rulings, laws and codes

as they apply to fireplaces and fireplace installations. Every

community is different so do not assume that because you

know the requirements for one locality, it will be the same in

the next. Avoid bureaucratic hassles and do your homework

WELL BEFORE you start your project!

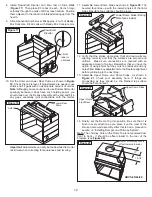

The Burntech® gas fireplace is designed to be installed

with a B-vent metal chimney system, UL 103 chimney.

Such chimney systems are acceptable where any

traditional masonry fireplace has been specified.

Note that the chimney system must always vent to the

outside of the building.

This Burntech® fireplace is intended as a supplemental heat

source only. It is not intended as a primary heat source.

It is the responsibility of the contractor installer (not the

manufacturer) to ensure that adequate combustion air is

provided for proper function of this fireplace. Fireplaces

take up a large volume of replacement air from outside the

house and if the house is of airtight construction, smoke

spillage may occur if proper draft is not achieved.

There are many conditions beyond a manufacturer’s

control when it comes to the operation of the fireplace.

The manufacturer cannot be responsible for “smoke free”

operation, nor can the manufacturer take on the responsibility

for problems with surrounding construction; chimneys that

have not been built at the right heights; system drafts caused

by faulty mechanical systems; adverse weather conditions

or any other inclement environmental situations over which

the manufacturer has no control.

Inspect all fireplace & chimney components for evidence

of damage prior to starting installation. Consult your local

distributor for replacement parts if necessary.

Under no circumstances should you make any adjustments

or modifications to the chimney system during the

installation procedure. If you do, you are not only liable

for negating the warranty, but you could very well cause a

serious malfunction of the fireplace. You must follow these

chimney instructions.

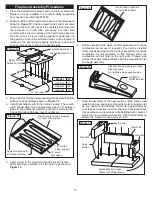

Chimney System Heights

When installed, the maximum overall height of the Fireplace is

40’-0” (forty feet). The minimum installed height of the

completed fireplace is 14’ 0” (fourteen feet), given that the

chimney is straight. If the chimney includes one or more offset

sections, the measurement is 17’ 0” (seventeen feet).

1)

2)

3)

4)

5)

6)