Commissioning the heating system

5

Logamax plus GB162-65/80/100 - Subject to modifications resulting from technical improvements!

16

5.2.2 Setting the DHW temperature

The boiler is factory-set to a DHW temperature of 60 °C.

This setting should prevent any legionella bacteria

present in the system from propagating. However, to be

able to meet the various requirements of different users,

the DHW temperature of your boiler can be adjusted.

If required, the boiler can be set to a lower DHW temper-

ature.

Please be aware that setting the boiler to a lower DHW

temperature will bring a slight risk of contamination by

legionella bacteria. If the DHW system is used on a daily

basis, there is virtually no risk of legionella bacteria prop-

agating.

If the DHW system is not used for a long period (e.g.

during a holiday) and a temperature of less than 60 °C

has been set, it is advisable to flush the hot water

cylinder before using it again.

Flushing means fully opening the hot water tap for some

time, so that fresh water will be supplied to the hot water

cylinder. Another alternative is to set the DHW tempera-

ture dial to the 60 °C position prior to a period of

absence.

Set the DHW temperature dial (fig. 17,

item 1

) to the

required temperature of the hot water in the hot water

cylinder (

fig. 17

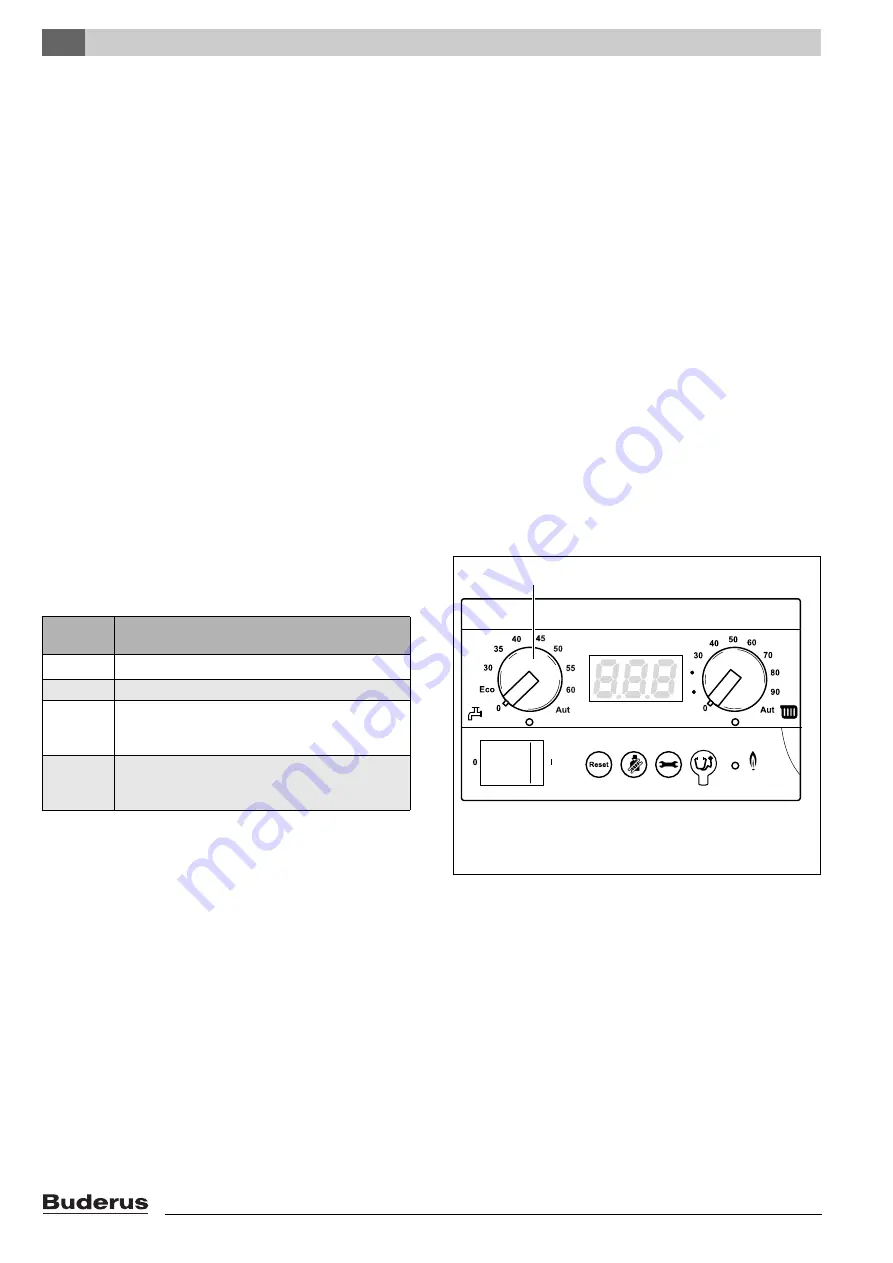

BC10 basic controller

1

Dial

position

Explanation

0

DHW mode is off (possibly only heating mode)

ECO

DO NOT use this setting!

30 – 60

The DHW temperature is set permanently on the

BC10 and cannot be changed with a room con-

troller (e. g. RC35).

Aut

The DHW temperature is set on the room control-

ler (e. g. RC35). If no room controller is connect-

ed, 60 °C is the maximum DHW temperature.

table 4 Settings on the DHW temperature dial