WARNING: Never operate unit without a filter or with filter access door removed. A failure to follow this warning could

result in fire, personal injury, or death.

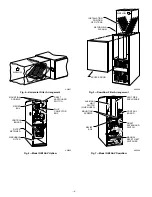

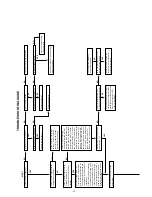

1. Downflow/Horizontal

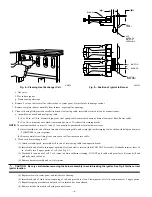

Each furnace requires 2 filters which are installed in the return-air duct. (See Fig. 4 and 5.) To remove filters for cleaning or replacement,

proceed as follows:

a. Disconnect electrical power before removing blower access door.

b. Remove screw from front of door and remove blower access door.

c. Reach up behind top plate, tilt filters toward center of return-air plenum, remove filters, and clean or replace as needed. Replace if torn

or if filter is disposable type.

d. If furnaces are equipped with permanent, washable filters, clean filters with tap water. Spray water through filter in opposite direction

of airflow.

e. Rinse and let dry. Oiling or coating of filters is not recommended or required.

f. Reinstall filters.

g. Replace blower access door.

h. Restore electrical power to furnace.

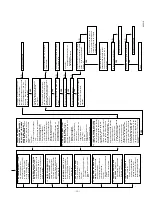

2. Upflow

Each furnace requires 1 or 2 filters which are installed in the blower compartment. (See Fig. 6.) To remove filters for cleaning or

replacement, proceed as follows:

a. Disconnect electrical power before removing access doors.

b. Remove blower and control access doors.

c. Release filter retainer from clip at front of furnace casing. (See Fig. 6.) For side return, clips may be used on either or both sides of the

furnace.

d. Slide filter(s) out.

e. Replace filter if torn or disposable type. If furnace is equipped with permanent, washable filters. Clean filters with tap water. Spray water

through filter in opposite direction of airflow.

f. Rinse and let dry. Oiling or coating of filter is not recommended or required.

g. Reinstall filter(s).

h. Replace blower and control access doors.

i. Restore electrical power to furnace.

B.

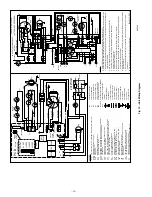

Blower Motor and Wheel

For long life, economy, and high efficiency, clean accumulated dirt and grease from the blower wheel and motor annually.

The following steps should be performed by a qualified service technician.

Some motors have prelubricated sealed bearings and require no lubrication. These motors can be identified by the absence of oil ports on each

end of the motor. For those motors with oil ports, lubricate motor every 5 years if motor is used on intermittent operation (thermostat FAN in

AUTO mode), or every 2 years if motor is in continuous operation (thermostat FAN in ON mode).

NOTE:

Remember to disconnect the electrical supply before removing access doors.

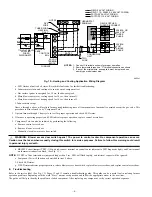

Table 1—Filter Size Information for Downflow/Horizontal Furnaces (In.)

FURNACE

CASING WIDTH

FILTER QUANTITY

AND SIZE

14-3/16

(2) 14 X 20 X 1

17-1/2

(2) 14 X 20 X 1

21

(2) 16 X 20 X 1

24-1/2

(2) 16 X 20 X 1

Table 2—Filter Size Information for Upflow Furnaces (In.)

FURNACE

CASING WIDTH

FILTER QUANTITY AND SIZE

Side Return

Bottom Return

14-3/16

(1) 16 X 25 X 1

(1) 14 X 25 X 1

17-1/2

(1) 16 X 25 X 1

(1) 16 X 25 X 1

21

(1) 16 X 25 X 1

(1) 20 X 25 X 1

24-1/2

(2) 16 X 25 X 1

(1) 24 X 29 X 1

—3—

Summary of Contents for GB1AAV

Page 15: ...15...