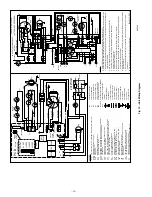

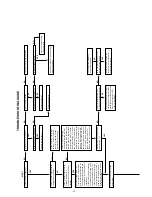

Fig.

12—Unit

Wiring

Diagram

A95335

PCB

BL

OWER

O

FF

DE

LAY

SE

LEC

T

IO

N CH

AR

T

90

SEC

135

SEC

180

SEC

225

SEC

GVR

H

I/L

O

RE

L

A

Y

SE

C-

1

SE

C-

2

PL

1

3

2

1

6

5

4

9

87

LE

D

TEST/TWIN

BL

OWER

OF

F

DE

LAY

G

R

Y

W

C

HU

M

HS

IR

ID

R

B

L

W

R

BL

OWER

SP

EED

SE

LEC

T

FU

1

C

OOL

HE

AT

L2

PL

3

PL

2

VA

C

120

L1

PR

1

1

2

1

2

3

PR

2

24 VA

C

-3A

FU

SE

SP

AR

E-

2

SP

AR

E-

1

EA

C-

1

EA

C-

2

C

1.5 A

MP

12

PL

5

WHT

BL

K

WHT

WHT

BLK

BLK

HS

I

BL

K

WHT

WHT

(C

OM

)

RE

D

(

L

O)

BL

U

(M

ED

LO

)

NO

TE

#

8

OL

ST

ART

BL

W

M

YE

L (

M

ED

H

I)

BL

K

(

H

I)

BR

N

BR

N

TRAN

BL

U

RE

D

BL

K

WHT

WHT (

C

OM

)

GR

N

CA

P

RE

D

NO

TE

#5

RE

D

OR

N

F

U

S

E

D

DI

SC

ON

NE

C

T

SWI

T

CH

(

W

HE

N REQ

’D

)

NO

TE

#4

FU

2

BL

K

WHT

GR

N

GR

N

JB

LEGEND

AL

S

A

U

X

IL

IA

RY

LI

M

IT

SWI

T

CH

,

OV

ER

TEM

P

. -

M

ANU

A

L

RE

SET

,

SPS

T-

(N

.C

.)

BL

W

R

BL

OWER

M

O

TOR

R

E

LA

Y,

SP

ST-

(N

.O

.)

BL

W

M

BL

OWER

M

O

TOR

C

A

P

C

AP

AC

IT

O

R

CP

U

M

IC

RO

PRO

C

E

S

S

O

R

AN

D

CI

RC

UI

TRY

D

S

S

D

RA

F

T

SA

F

E

G

U

A

R

D SW

IT

CH

EA

C-

1

E

L

E

CT

RO

NI

C AIR

C

L

EA

NE

R CO

NNE

CTI

O

N (115

V

A

C 1.

5

A

M

P

M

A

X

.)

EA

C-

2

E

L

E

CT

RO

NI

C AIR

C

L

EA

NE

R CO

NNE

CTI

O

N (C

OM

MO

N)

FL

FU

SI

BLE LI

NK

FR

S

F

LA

ME

R

O

LL

OU

T S

W

.

-M

AN

UA

L R

ESE

T,

S

PST-

(N

.C

.)

F

S

E

F

LAM

E

PR

OV

IN

G ELE

C

T

R

OD

E

FU

1

F

U

SE,

3

A

M

P

, AU

TOM

O

TIV

E

BLAD

E TYP

E

,

FA

CTO

R

Y

I

N

S

T

ALL

E

D

F

U

2

F

US

E

OR

C

IR

C

U

IT

BR

E

A

K

E

R

CU

RR

E

N

T

I

N

T

E

RR

UP

T

D

E

VI

CE

(F

IE

LD I

N

ST

ALLE

D &

S

U

P

P

LI

ED)

G

V

G

AS VA

LVE-

R

E

DU

ND

ANT

O

PER

ATO

R

S

G

V

R

G

AS VA

LVE RE

LAY

, DP

ST-

(N

.O

.)

HI

/L

O

B

L

O

WER

M

O

TOR

S

PEE

D CH

ANG

E

RE

LAY

, SPD

T

HS

I

H

OT SU

RFA

C

E I

G

N

ITOR (

115 VAC

)

HS

IR

HO

T SU

RFA

C

E I

G

N

ITO

R RE

LAY

, SPS

T-

(N

.O

.)

HU

M

24V

AC

HU

M

ID

IFI

ER

C

O

N

N

EC

TI

ON

(

.5

A

M

P

.

MA

X.

)

ID

M

INDU

CE

D DRA

FT MO

TO

R

ID

R

INDU

CE

D DRA

FT RE

LAY

, SPS

T-

(N

.O

.)

IL

K

B

LO

W

E

R AC

CE

S

S

PA

N

E

L

IN

TE

R

L

O

C

K

SW

IT

CH

, SP

ST

-(

N

.O.

)

JB

JU

N

C

TI

ON

B

O

X

LE

D

L

IG

H

T

-E

M

ITT

IN

G DI

OD

E FOR

S

T

AT

US CO

DE

S

LG

PS

LO

W G

AS

PR

ES

SUR

E

SWIT

CH

,

SPS

T-

(N

.O

.)

LS

LI

MI

T SWI

T

CH

, AU

TO RE

SET

, SPS

T(

N.

C.

)

O

L

AU

TO

-R

ESE

T IN

TER

N

AL M

O

TO

R O

VER

LOA

D

TEM

P

. SW.

P

C

B

P

RI

NT

E

D

CI

RC

UI

T

B

O

A

R

D

P

L

1

9

-C

IR

CU

IT

CO

NN

EC

T

O

R

P

L

2

2

-C

IR

CU

IT

PC

B CO

NN

E

C

T

O

R

P

L

3

3

-C

IR

CU

IT

ID

M C

O

N

N

E

C

T

O

R

PL5

2

-C

IR

C

U

IT

H

S

I/

P

C

B CO

NN

EC

TOR

PR

S

P

R

ESS

UR

E S

W

IT

C

H

, S

PST

-(

N.

O

.)

TE

ST/

T

W

IN

C

O

M

PO

NEN

T

TEST

& TW

IN

TER

M

IN

A

L

TR

AN

TR

ANS

F

O

R

M

E

R-115V

AC/

24VA

C

JU

NC

TI

ON

UN

M

A

RK

ED TE

RM

IN

AL

PC

B TER

M

IN

A

L

FA

CTO

R

Y

WI

RI

NG

(115VA

C

)

FA

CTO

R

Y

W

IRI

NG

(

24VA

C

)

FI

ELD

WI

RI

NG

(115VA

C

)

FI

ELD

W

IRI

NG

(

24VA

C

)

CO

ND

UC

TO

R

ON

PC

B

FI

ELD

W

IRI

NG

TE

RM

IN

AL

F

IE

L

D GR

OU

ND

EQ

UI

PM

EN

T G

R

O

U

N

D

FI

ELD

SP

LI

C

E

PLU

G

RE

CEP

TAC

LE

L1

NE

UTR

A

L

L1

BLW

R

H

I/L

O

TO 11

5V

A

C

FI

E

L

D DI

S

C

ONNE

CT

NOTE

#4

EQ

UI

PM

EN

T G

R

O

U

N

D

SP

ARE

-2

HE

AT

SP

ARE

-1

C

OOL

NO

TE

#8

CO

M

HS

IR

EA

C-

1

ST

ART

OL

CO

M

HI

M

E

D HI

ME

D

L

O

LO

BLW

M

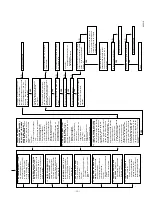

SCH

E

MATIC DIA

G

R

A

M

(NAT

URAL

GAS &

P

R

OPANE

)

EA

C-

2

1

1

HS

I

2

PL5

2

PL2

3

PL3

PR

2

115V

AC

PR

1

TR

AN

24VA

C

1

2

ID

R

T

E

S

T

/T

WIN

FU

1

NO

TE

#6

CA

P

L2

PL1

GV

2-C

1-M

3-P

NO

TE

#5

8

FS

E

9

6

5

CP

U

HS

IR

ID

R

BLW

R

Y

G

C

R

W

GV

R

-2

SE

C-

1

H

I/L

O

GV

R

GV

R

-1

SE

C-

2

NOT

ES:

32

2869

-101

REV

. C

1.

If

any

of t

he

or

ig

in

a

l equ

ip

m

e

n

t w

ire

is

r

epl

a

ced

use

wi

re

r

a

ted

for

1

0

5

°C

.

2.

In

duce

r (I

DM

) an

d b

low

er

(

B

L

W

M

) mo

tor

s co

nta

in i

n

te

rn

a

l aut

o-

re

set

the

rm

a

l o

ver

lo

a

d

sw

itche

s (

O

L)

.

3.

Bl

o

w

e

r

mo

tor

sp

eed

sel

e

cti

ons

ar

e f

o

r ave

ra

g

e

con

d

iti

o

n

s, se

e i

n

st

al

la

tion

in

str

u

ct

io

ns f

o

r de

tai

ls

o

n

op

tim

u

m

spe

ed

sel

e

cti

o

n.

4.

U

se o

n

ly

co

ppe

r w

ir

e

bet

we

en

th

e d

isco

nn

ect sw

itch

an

d th

e f

u

rn

a

ce j

u

n

cti

on

bo

x (

JB)

.

5.

T

h

is

w

ir

e

m

u

st

be

con

nect

ed

to f

u

rn

a

ce sh

eet

me

tal

fo

r con

tr

o

l to

de

tect

flam

e.

6.

R

e

p

la

ce o

n

ly

w

ith

a 3

am

p

fuse

.

7.

Ye

llo

w

lead

no

t o

n

a

ll m

o

to

rs

.

8.

Bl

o

w

e

r-

o

n d

e

la

y,

gas

hea

ting

45

seco

nds,

coo

lin

g o

r

hea

t p

u

m

p

2

seco

nd

s.

9.

Bl

o

w

e

r-

o

ff d

e

la

y,

gas

hea

ting

90

, 13

5,

180

o

r 2

2

5

seco

nds,

coo

lin

g o

r

hea

t p

u

m

p

9

0

se

con

d

s.

(1

3

5

se

cond

s on

ly

on

som

e

mo

del

s)

1

0

.

Ig

n

itio

n

-lo

cko

u

t wi

ll o

ccu

r a

ft

e

r fo

u

r co

n

se

cu

tive

u

n

su

cce

ssfu

l t

ria

ls-fo

r-ig

n

iti

o

n

.

C

o

n

tro

l w

ill a

u

to

-re

se

t

af

ter

th

re

e h

o

u

rs.

1

1

.

W

h

e

n

u

se

d

a

u

xilia

ry lim

it switch

(AL

S

) is o

n

d

o

wn

flo

w

mo

d

e

ls o

n

ly

. W

h

e

n

u

se

d

FL

is o

n

u

p

flo

w

mo

d

e

ls o

n

ly.

12

.

S

o

m

e

m

o

d

e

ls

m

a

y h

a

ve

spad

e

qui

ck co

nn

ect t

e

rm

in

al

s.

BLK

OM

SW

2

SW

1

OM

2

3

4

7

1

OM

HU

M

ID

M

IL

K

DS

S

ALS

PR

S

IL

K

L1

NE

UTR

A

L

ID

M

(W

H

E

N US

E

D

)

NO

TE

#11

NO

T US

ED

NO

T US

ED

NO

T US

ED

GR

N

2-

C

FS

E

1-

M

3-

P

GV

BL

U

YE

L

PR

S

DS

S

AL

S

(W

HE

N US

E

D

)

NOTE

#12

WH

T

FR

S1

FR

S2

LS

FL

(W

H

E

N US

E

D

)

(N

OT

ON

A

L

L

MO

DE

L

S

)

NO

TE

#9

FR

S1

FR

S2

LS

FL

(W

H

E

N US

E

D

NO

TE

#12

—10—

Summary of Contents for GB1AAV

Page 15: ...15...