42

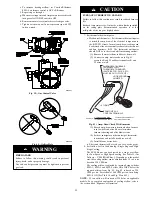

furnace blower motor BLWM will drop the blower

airflow to 65 percent of low--cooling airflow for a

maximum of 10 minutes each cooling cycle or until

the R--to--G circuit closes or the demand for

dehumidification is satisfied. Low--cooling airflow is

the true on--board CF (continuous fan) selection as

shown in Fig. 42.

b. When the R--to--Y/Y2 circuit is closed, R--to--G circuit

is open, and there is a demand for dehumidification,

the furnace blower motor BLWM will drop the blower

airflow to 65 percent of high--cooling airflow for a

maximum of 10 minutes each cooling cycle or until

the R--to--G circuit closes or the demand for

dehumidification is satisfied. High--cooling airflow is

based on the A/C (air conditioning) selection shown in

Fig. 42.

c. When the “call for cooling” is satisfied and there is a

demand for dehumidification, the cooling blower--off

delay is decreased from 90 seconds to 5 seconds.

5.

Continuous Blower Mode

When the R--to--G circuit is closed by the thermostat, the

blower motor BLWM will operate at continuous blower

airflow. Continuous blower airflow selection is initially

based on the CF (continuous fan) selection shown in Fig.

42. Factory default is shown in Fig. 42. Terminal EAC--1

is energized as long as the blower motor BLWM is

energized.

During a call for heat, the furnace control CPU will

transition the blower motor BLWM to continuous blower

airflow, heating airflow, or the mid--range airflow,

whichever is lowest. The blower motor BLWM will

remain ON until the main burners ignite then shut OFF

and remain OFF for the blower--ON delay (25 seconds in

heat), allowing the furnace heat exchangers to heat up

more quickly, then restarts at the end of the blower--ON

delay period at heating airflow.

The

blower

motor

BLWM

will

revert

to

continuous--blower airflow after the heating cycle blower

off--delay is completed.

When the thermostat “calls for low--cooling”, the blower

motor BLWM will switch to operate at low--cooling

airflow. When the thermostat is satisfied, the blower motor

BLWM will operate an additional 90 seconds at cooling

airflow before transitioning back to continuous--blower

airflow.

When the thermostat “calls for high--cooling”, the blower

motor BLWM will operate at high cooling airflow. When

the thermostat is satisfied, the blower motor BLWM will

operate an additional 90 seconds at high--cooling airflow

before transitioning back to continuous--blower airflow.

When the R--to--G circuit is opened, the blower motor

BLWM will continue operating for an additional 5

seconds, if no other function requires blower motor

BLWM operation.

Continuous Blower Speed Selection from Thermostat

To select different continuous--blower airflow from the

room thermostat, momentarily turn off the FAN switch or

push button on the room thermostat for 1--3 seconds after

the blower motor BLWM is operating. The furnace control

CPU will shift the continuous--blower airflow from the

factory setting to the next highest CF selection airflow as

shown in Fig. 42. Momentarily turning off the FAN switch

again at the thermostat will shift the continuous--blower

airflow up one more increment. If you repeat this

procedure enough you will eventually shift the

continuous--blower airflow to the lowest CF selection as

shown in Fig. 42. The selection can be changed as many

times as desired and is stored in the memory to be

automatically used following a power interruption.

NOTE

: If the blower--off delay is set to the maximum (SW1--7

and 8 are ON), the adjustable continuous--fan feature is locked

(i.e., fan speed cannot be changed from its current setting).

6.

Heat pump

See Fig. 27 -- 28 for thermostat connections.

When installed with a heat pump, the furnace control auto-

matically changes the timing sequence to avoid long blow-

er off times during demand defrost cycles. Whenever

W/W1 is energized along with Y1 or Y/Y2, the furnace

control CPU will transition to or bring on the blower mo-

tor BLWM at cooling airflow, heat airflow, or the mid--

range airflow, whichever is lowest. The blower motor

BLWM will remain on until the main burners ignite then

shut OFF and remain OFF for 25 seconds before coming

back on at heating airflow. When the W/W1 input signal

disappears, the furnace control begins a normal inducer

post--purge period while changing the blower airflow. If

Y/Y2 input is still energized the furnace control CPU will

transition the blower motor BLWM airflow to cooling air-

flow. If Y/Y2 input signal disappears and the Y1 input is

still energized the furnace control CPU will transition the

blower motor BLWM to low--cooling airflow. If both the

Y1 and Y/Y2 signals disappear at the same time, the blow-

er motor BLWM will remain on heat airflow for the select-

ed blower--OFF delay period. At the end of the blower--

OFF delay, the blower motor BLWM will shut OFF unless

G is still energized, in which case the blower motor

BLWM will operate at continuous blower airflow.

7.

Component test

The furnace features a component test system to help diag-

nose a system problem in the case of a component failure.

To initiate the component test procedure, ensure that there

are no thermostat inputs to the control and all time delays

have expired. Turn on setup switch SW1--6. (See Fig. 23)

NOTE

: The component test feature will not operate if the control

is receiving any thermostat signals or until all time delays have

expired.

The component test sequence is as follows:

a. The furnace control CPU turns the inducer motor ON

at 50% torque and keeps it ON through step c.

b. After waiting for 15 seconds of inducer only

operation, the furnace control CPU turns the hot

surface ignitor ON for 15 seconds, then OFF.

c. The furnace control CPU then turns the blower motor

BLWM on at mid--range airflow for 15 seconds, then

OFF.

d. After shutting the blower motor OFF the furnace

control CPU switches the inducer OFF

.

NOTE

: The EAC terminals are energized when the blower is

operating.

After the component test is completed, 1 or more status codes

(11, 25, 41 or 42) will flash. See component test section or

Service Label (Fig. 38) for explanation of status codes.

NOTE

: To repeat component test, turn setup switch SW1--6 to

OFF and then back ON.

Wiring Diagrams

Refer to Fig. 45 for wiring diagram.

Troubleshooting

Refer to the service label. (Fig. 38), and wiring diagram (Fig. 45)

can be a useful tool in isolating furnace operation problems. The

Guide will help to identify the problem or failed component.

After replacing any component, verify correct operation

sequence.